Blog

Wholesale Stone CNC Router:Cutting for Granite and Marble

As the stone processing industry evolves, CNC technology has become essential for enhancing production efficiency and cutting precision. With the growing demand for bulk purchases and large-scale production, wholesale Stone CNC Router is gaining popularity in the market. These high-precision machines not only cut hard stones like granite and marble accurately but also boost productivity, meeting both custom and high-volume production needs. Whether you’re a stone manufacturer, contractor, or artisan, choosing the right Stone CNC Router can streamline your workflow, save time, and cut costs.This article will explore the advantages of wholesale Stone CNC Routers and their widespread applications in granite and marble cutting.

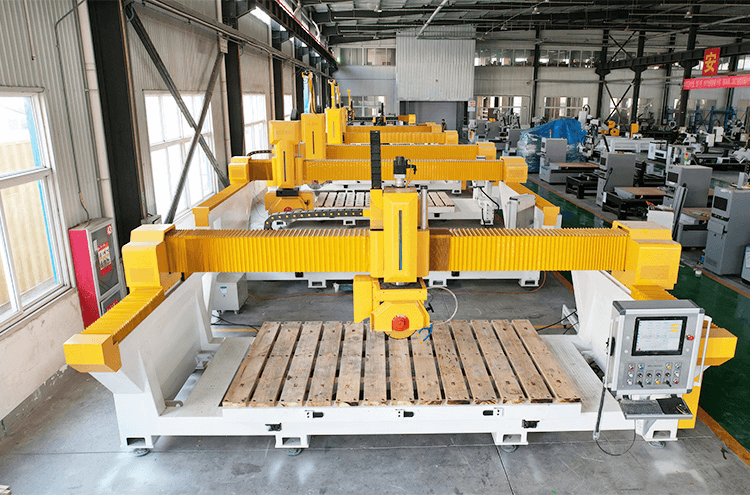

Wholesale Stone CNC Router

How Stone CNC Routers Work

- The process of using a stone CNC router involves several key steps:

- Design: The first step is to create a digital design of the stone component or product using CAD software. This design contains all the necessary dimensions and specifications for the stone piece.

- Programming: The CAD file is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program contains the instructions for the CNC router, including tool paths, cutting speeds, and feed rates.

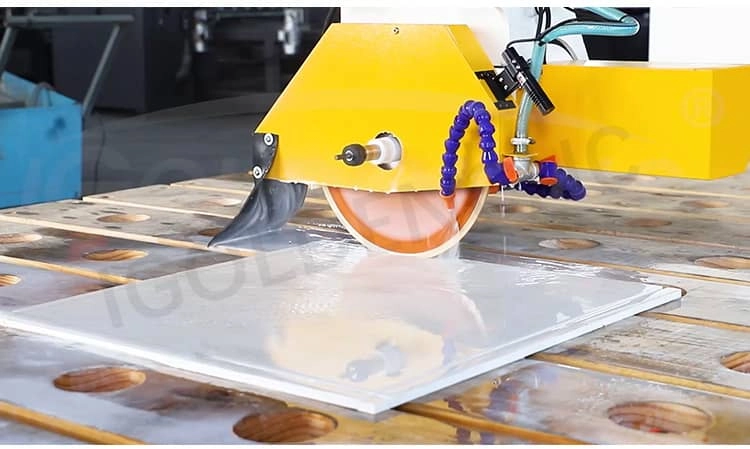

- Machining: The CNC router is set up with the appropriate cutting tools, usually diamond-tipped tools for granite and marble. The machine follows the programmed instructions to cut, carve, or shape the stone material. The router moves in multiple axes to achieve the desired geometry.

- Finishing: After the initial machining, the stone component may undergo additional finishing processes, such as polishing or edge profiling, to achieve the desired surface finish and appearance.

Advantages of Wholesale Stone CNC Router

When it comes to large-scale stone cutting, investing in wholesale Stone CNC Routers offers a variety of key advantages that contribute to both cost savings and enhanced productivity. Let’s explore some of the key benefits:

Precision and Accuracy

One of the primary benefits of using CNC routers for stone cutting is the high level of precision they provide. Traditional methods, such as manual cutting or using standard saws, often result in inconsistencies. In contrast, CNC routers can achieve tight tolerances and intricate designs with ease, ensuring that each piece of stone is cut exactly as required. This level of accuracy is particularly important when working with expensive materials like granite and marble, where even a small mistake can lead to significant financial loss.

Increased Productivity

CNC routers can operate continuously with minimal supervision, allowing for round-the-clock production. This automation increases the output rate of stone cutting, enabling manufacturers to meet larger orders in a shorter time frame. For businesses involved in wholesale stone production, this efficiency directly translates to higher profit margins and the ability to handle more significant, high-volume projects.

Customization and Flexibility

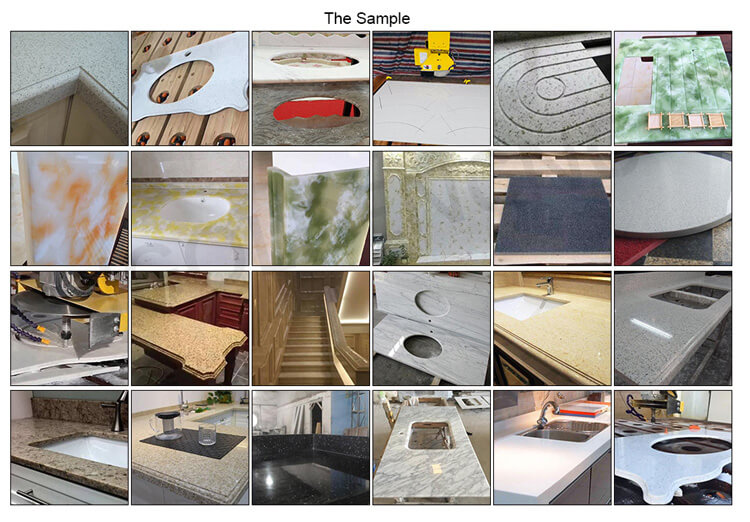

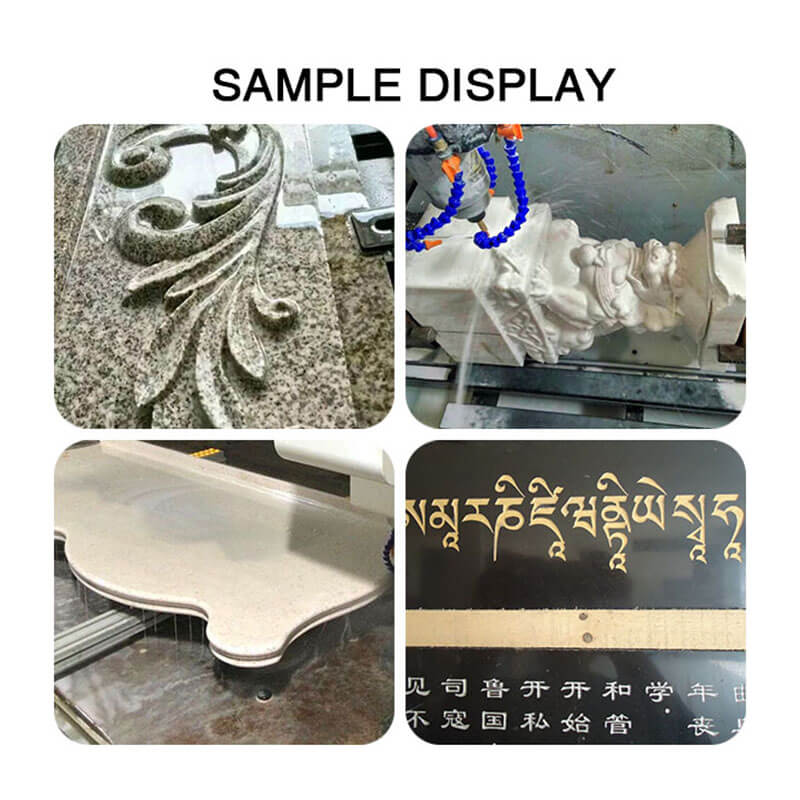

Stone CNC routers are capable of creating a wide variety of designs, from basic cuts to more complex, customized engravings. This flexibility makes them suitable for a broad range of applications, including countertops, sculptures, gravestones, and architectural elements. The ability to modify designs through software means that manufacturers can respond to customer demands quickly, creating unique products without the need for expensive molds or tools.

Reduced Labor Costs

Traditional stone cutting and engraving require skilled laborers to operate heavy machinery and ensure precision. With CNC routers, much of the manual labor is eliminated. Once programmed, the machine can carry out tasks autonomously, reducing the need for multiple operators and minimizing human error. This leads to reduced labor costs and a more streamlined operation.

Lower Waste and Material Costs

Another major advantage of CNC routers is their ability to minimize material waste. The precision of these machines means that cuts are made with minimal excess, which helps to preserve valuable materials like granite and marble. This not only cuts down on costs but also helps companies maintain a more sustainable production process by reducing scrap.

Applications of Stone CNC Router in Granite and Marble Cutting

Stone CNC Routers are incredibly versatile machines that can cut large slabs of granite and marble into smaller, precise pieces for applications like countertops, tiles, and architectural panels. They also allow users to create intricate engravings and detailed patterns. These machines have transformed the production of tombstones and memorial monuments by enabling fast, accurate carving of text, symbols, and images on stone surfaces. As a result, businesses can reduce labor time, increase output, and maintain exceptional quality for both individual and large-scale production.

Why Choose Wholesale Stone CNC Router?

For businesses looking to invest in CNC technology for stone cutting, purchasing wholesale Stone CNC Routers offers several advantages. Buying in bulk reduces the overall cost per machine, which makes high-end technology more accessible for companies of all sizes. In addition, wholesale suppliers often offer better warranty packages, customer support, and after-sales services, ensuring that businesses receive ongoing support as they integrate CNC routers into their operations.

Furthermore, buying wholesale provides the opportunity to scale operations. Whether upgrading existing equipment or expanding production capacity, wholesale purchases allow businesses to obtain multiple machines at a competitive price, ensuring they are well-equipped to handle larger orders and growing demands.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.