Blog

Transform Your Stone with CNC Cut Stone

Stone has been a cornerstone of human civilization for millennia. From ancient monuments to modern-day architecture, stone has shaped our buildings, sculptures, and infrastructure. Historically, cutting stone required immense skill and painstaking labor, often limiting the complexity and precision of designs. However, the advent of CNC (Computer Numerical Control) technology has radically transformed how stone is shaped and cut, making intricate designs, faster production, and minimal waste possible.

CNC cut stone technology has become a game-changer in the stone industry, providing unmatched precision, versatility, and efficiency. Whether you’re working with granite, marble, limestone, or other materials, CNC stone cutting allows for high-quality, complex, and customized results.

What is CNC Stone Cutting?

At its core, CNC stone cutting is a technology that utilizes computer-controlled machines to cut, carve, and engrave stone with a high level of accuracy. Unlike traditional stone cutting methods, which rely on manual tools and labor-intensive processes, CNC machines are automated and follow pre-programmed instructions from CAD (Computer-Aided Design) software. This enables the machine to create precise cuts and intricate designs without the errors or inconsistencies that can occur with manual work.

CNC machines for stone cutting typically use diamond-tipped blades or water jets to cut through the material. These machines can work with a variety of stones, including hard materials like granite and quartz, as well as softer stones like marble or sandstone. The ability to program specific designs allows the machine to perform tasks like cutting straight lines, creating curves, engraving text, or even crafting three-dimensional shapes.

Key Advantages of CNC Stone Center

Precision Beyond Compare

One of the most significant advantages of CNC stone cutting is its incredible precision. CNC machines are capable of cutting stone to extremely tight tolerances, which is essential for applications where accuracy is critical. Whether you’re creating custom countertops, intricate sculptures, or architectural elements, the level of control offered by CNC technology ensures flawless results every time.

The high level of precision also makes CNC stone cutting ideal for complex designs that would be challenging or impossible to achieve with traditional methods. Whether it’s fine detailing for monuments or customized engravings for memorials, CNC machines can handle the most intricate patterns with ease.

Speed and Efficiency

In contrast to traditional stone cutting, which is often slow and labor-intensive, CNC machines can complete tasks at significantly faster speeds. A task that might take days with manual tools can often be completed in a matter of hours using CNC technology. This efficiency reduces the overall production time and allows for faster turnaround on projects, which is especially beneficial in high-demand environments such as construction, interior design, or monument making.

Moreover, the automated nature of CNC stone cutting ensures that each cut is consistent, reducing the time spent on adjustments or rework. With CNC, there’s no need to worry about human error or the variation between different workers, which is often the case in traditional stone cutting methods.

Customization at Its Best

Another major benefit of CNC stone cutting is its ability to handle customization with ease. Whether you’re designing a one-of-a-kind countertop, a personalized memorial, or a bespoke piece of art, CNC technology allows you to create unique, tailor-made pieces. The machine can cut, engrave, and shape stone into any form, from intricate carvings to complex geometric patterns, based on the specifications you provide.

This level of customization opens up endless possibilities for both artists and manufacturers. You can easily adapt designs as needed and even modify the size, shape, or details without losing quality. This flexibility is a significant advantage over traditional methods, which often require more time and effort to achieve similar results.

Minimal Waste and Increased Sustainability

CNC stone cutting is more efficient in terms of material usage compared to traditional cutting methods. The precision of CNC machines allows for better optimization of the stone, meaning less material is wasted during the cutting process. Additionally, because the cuts are so accurate, you can maximize the use of every piece of stone, turning even small offcuts into usable materials.

This efficiency not only saves money on material costs but also helps reduce environmental impact. By minimizing waste, CNC stone cutting promotes more sustainable practices in industries that rely heavily on stone, such as construction and manufacturing.

How CNC Stone Router Works: A Step-by-Step Overview

To fully understand the impact of CNC stone router, it’s essential to explore how the process works. Here’s a simplified breakdown of how CNC technology is used to cut and shape stone:

1. Designing the Project

The first step in CNC stone cutting is creating or importing a design. This is done using CAD software, which allows designers to create precise blueprints for the project. These designs can range from simple shapes to complex patterns or even three-dimensional models. CAD software enables designers to visualize the final result and make any necessary adjustments before sending the design to the CNC machine.

2. Transferring the Design to the CNC Machine

Once the design is finalized, it is converted into a machine-readable format, typically a G-code or other numerical instructions. This code tells the CNC machine exactly how to move, what speed to operate at, and how deep to cut into the stone. The CNC machine then interprets these instructions and prepares to cut the stone according to the design.

3. Setting Up the Stone

Before cutting begins, the operator places the stone onto the CNC machine’s work surface and securely clamps or fixes it in place to prevent any movement during the cutting process. Some CNC machines have advanced positioning systems that can automatically align the stone, ensuring optimal cutting alignment.

4. Cutting and Shaping the Stone

The CNC machine uses a variety of tools to cut and shape the stone, depending on the design. These tools can include diamond-tipped saws, rotary bits, and water jets. The machine moves according to the pre-programmed design, performing tasks like cutting, engraving, or carving the stone with high accuracy. For some projects, multiple passes or different tools are required to achieve the final result.

5. Finishing and Polishing

After the cutting process, the stone may undergo additional finishing steps to achieve the desired texture, smoothness, or shine. CNC machines can also be equipped with polishing heads or grinders that can smooth rough edges or polish the surface to a high gloss. The final result is a clean, precise, and aesthetically pleasing stone piece ready for use.

6. Quality Control

Once the cutting and finishing are complete, the stone is inspected to ensure it meets the required specifications. CNC machines provide high repeatability and consistency, but quality control is still essential to ensure every piece is perfect.

Applications of CNC Stone Cutting

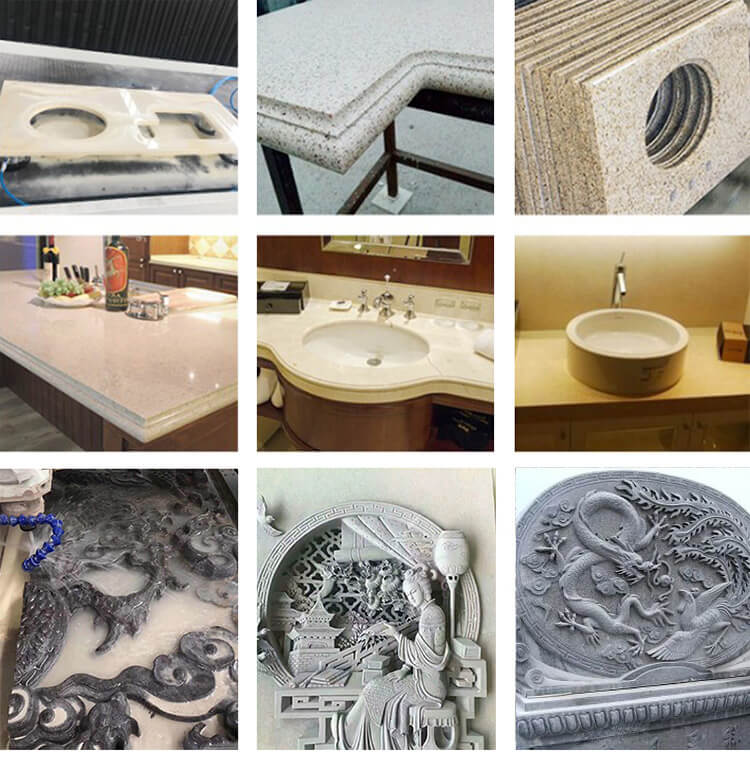

The versatility and precision of CNC stone cutting make it ideal for a wide range of industries and applications. Some of the most common uses of CNC stone cutting include:

1. Countertops and Kitchen Design

CNC stone cutting is widely used to create custom countertops from materials like granite, marble, and quartz. With CNC technology, designers can create precise cuts that fit seamlessly into kitchens and bathrooms. The operator can also use the machine to add intricate edges, custom designs, and decorative elements to countertops, giving homeowners a truly unique piece.

2. Architectural Stonework

In architecture, CNC stone cutting is used to create intricate details for building facades, columns, arches, and other architectural elements. The ability to create complex patterns and shapes with high accuracy has made CNC technology a vital tool in modern architecture, allowing for both aesthetic and functional designs.

3. Monuments and Memorials

CNC machines are commonly used to create monuments, gravestones, and memorial plaques. The ability to engrave detailed text, images, and designs onto stone surfaces has revolutionized the memorial industry. Families can now commission highly personalized memorials that reflect the personality of their loved ones.

4. Sculpture and Art

CNC stone cutting has become a valuable tool for artists looking to create intricate sculptures and stone art. Whether it’s a small decorative piece or a large-scale installation, CNC technology allows artists to execute their designs with incredible precision and detail. This has opened up new possibilities for creative expression, as complex designs can now be translated into stone with ease.

Conclusion: Embrace the Future of Stone Cutting

CNC stone cutting has dramatically changed the way we approach stonework, offering precision, speed, and customization that were once unimaginable. Whether you’re a contractor, artist, or business owner, CNC technology can help you create beautiful, functional, and complex stone pieces with unmatched accuracy. By embracing CNC stone cutting, you can not only enhance your production capabilities but also explore new creative possibilities that will set your work apart.

As the stone industry continues to evolve, CNC technology will remain at the forefront of innovation, allowing businesses and artisans alike to push the boundaries of design and craftsmanship. Whether for residential, commercial, or artistic applications, CNC stone cutting is the key to transforming stone into works of art and functional masterpieces.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.