Blog

Top Stone CNC Router for Professional Stone Carving&Sculpting

In the world of professional stoneworking, precision, efficiency, and reliability are essential. Whether creating intricate carvings or shaping raw materials into beautiful sculptures, a stone CNC router has become an indispensable tool for artisans and manufacturers alike. With advanced capabilities, these machines ensure high-quality results for materials such as marble, granite, and sandstone.

This guide will explore the key features, benefits, and applications of stone CNC routers, helping you choose the best machine for your professional needs.

What Is a Stone CNC Router?

A stone CNC router is a computer-controlled cutting and engraving machine specifically designed for stone materials. Unlike manual methods, which can be time-consuming and less precise, these routers automate the carving and sculpting process. Using advanced software, they translate digital designs into detailed physical creations, making them perfect for both functional and decorative projects.

Stone CNC routers are widely used in industries such as architecture, monument production, interior design, and fine art. They handle tasks ranging from engraving inscriptions to sculpting complex three-dimensional shapes.

Key Features of Stone CNC Routers

- Robust Construction:Stone CNC routers feature heavy-duty frames made from materials like cast iron or steel. These provide the durability needed to handle hard materials like granite and marble while minimizing vibrations for precise cuts.

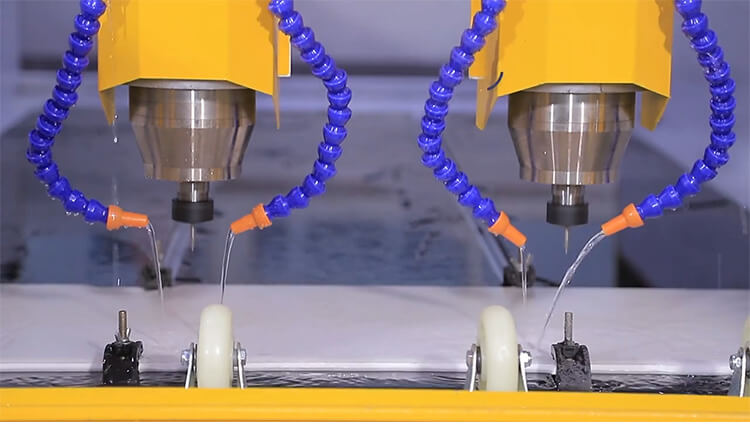

- Advanced Cutting Tools:Equipped with diamond-tipped tools and high-speed spindles, stone CNC routers can perform intricate engraving, cutting, and polishing tasks with ease.

- Versatile Functionality:These machines support a range of operations, including 2D engraving, 3D carving, edge shaping, and surface polishing.

- CAD/CAM Software Compatibility:Integrated software allows users to create custom designs, load pre-made templates, or convert scanned images into carving instructions.

- Cooling and Dust Systems:Water cooling systems protect tools from overheating during continuous operation. Additionally, dust collection systems maintain a clean working environment and reduce wear and tear.

Benefits of Using a Stone CNC Router

1. High Precision and Accuracy

Stone CNC routers offer unparalleled precision, making them ideal for detailed projects such as inscriptions, patterns, and relief sculptures.

2. Improved Efficiency

By automating carving and cutting processes, these machines significantly reduce production times, enabling higher output.

3. Custom Design Capabilities

With CAD/CAM software, users can create and reproduce complex custom designs, enhancing the uniqueness and value of their products.

4. Cost-Effectiveness

Despite the initial investment, stone CNC routers save costs in the long term by minimizing material waste and labor expenses.

5. Consistent Quality

These machines ensure uniformity in every project, delivering professional results that meet industry standards.

Applications of Stone CNC Router

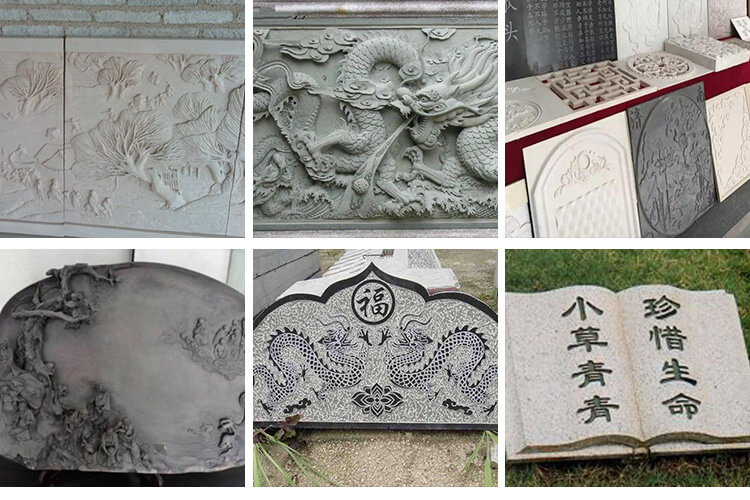

1. Monument and Tombstone Production

Stone CNC routers are widely used to engrave names, dates, and decorative elements on tombstones and monuments.

2. Architectural Stonework

From intricate facades to customized columns and balustrades, these routers help architects bring their visions to life.

3. Interior and Exterior Design

Create custom countertops, backsplashes, and floor inlays with precision and style.

4. Fine Art and Sculptures

Artists and sculptors use stone CNC routers to craft stunning three-dimensional art pieces with detailed features.

5. Signage and Logos

Engrave company logos or decorative text on stone for durable and attractive signage.

How to Choose the Best Stone CNC Router

1. Material Compatibility:Ensure the machine can process the types of stone you frequently use, such as granite, marble, or sandstone.

2. Table Size and Work Area:Select a router with a worktable large enough for your typical projects, whether small plaques or large stone slabs.

3. Spindle Power:Higher spindle power enables the machine to cut harder materials and handle larger projects efficiently.

4. Software Features:Look for user-friendly software that offers flexibility for design creation and file import.

5. Durability and Maintenance:Choose a router with robust construction and easy-to-maintain components to ensure long-term reliability.

IGOLDENCNC has Top Stone CNC Routers

At IGOLDENCNC, we pride ourselves on providing cutting-edge CNC solutions tailored to professional stoneworking. Our stone CNC routers combine advanced technology, durable construction, and user-friendly interfaces to meet the highest industry standards.

What Sets IGOLDENCNC Apart?

-

Extensive Range of Models

We offer a variety of stone CNC routers, from entry-level machines for small workshops to industrial-grade systems for large-scale production. -

Customizable Options

Our routers are customizable to suit specific applications, ensuring optimal performance for your projects. -

Affordable Pricing

We deliver high-quality machines at competitive prices, maximizing your return on investment. -

Comprehensive Support

Our team provides installation assistance, training, and ongoing technical support to help you get the most out of your machine.

The stone CNC router is a game-changer for professionals in the stoneworking industry. Whether you’re carving intricate designs, cutting precise shapes, or engraving text, these machines offer unmatched efficiency and accuracy.By investing in a high-quality stone CNC router from IGOLDENCNC, you can elevate your craftsmanship, expand your service offerings, and meet the demands of clients seeking premium stone products.

Contact us today to learn more about our stone CNC routers and discover how they can transform your stoneworking projects!

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.