Blog

Top CNC Machine for Stone Cutting: Perfect for Marble, Granite & More

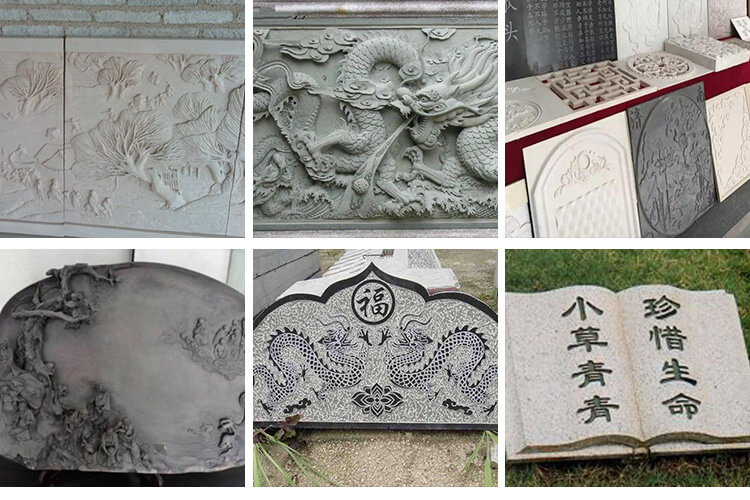

When it comes to cutting and shaping stone materials, CNC machine for stone cutting offer unmatched precision and efficiency. These machines handle everything from delicate engravings to large-scale stone processing, making them ideal for industries like construction, interior design, and monument making. At IGOLDENCNC, we provide top-tier CNC machines designed for cutting marble, granite, quartz, and other stone types. In this article, we’ll highlight the best CNC machines for stone cutting, their benefits, and how they can enhance your business.

What is a CNC Machine for Stone Cutting?

A CNC machine for stone cutting uses computer-controlled technology to guide cutting tools across a stone surface. Unlike manual methods, these machines offer high precision and can execute complex shapes and designs. Industries such as home decor, signage, and monument engraving depend on CNC stone cutters for their accuracy and speed. Benefits of Using CNC Machines for Stone Cutting.

Precision and Accuracy

CNC machines provide precise cuts, achieving exact shapes and designs with minimal error. They excel in creating complex patterns, whether you’re cutting countertops, engraving artwork, or shaping stones for monuments.

Versatility

CNC machines handle various materials, including granite, marble, quartz, and limestone. This versatility makes them suitable for a wide range of projects, from rough cutting to detailed engraving.

Increased Efficiency

CNC machines run faster than manual methods, which reduces production time significantly. They can operate for long hours without compromising quality, improving overall output and reducing costs in the long run.

Cost-Effectiveness

Though the initial investment may be high, CNC machines lower long-term costs. With reduced labor expenses, faster production, and less material waste, businesses can achieve a lower cost per unit over time.

Top CNC Machines for Stone Cutting at IGOLDENCNC

At IGOLDENCNC, we offer several models of CNC machines specifically designed for stone cutting. Below are some of our top machines:

5-Axis CNC Stone Cutting Bridge Saw

The 5-axis CNC stone cutting bridge saw is ideal for cutting large stone slabs with precision. This machine combines the functions of a saw blade and CNC router tools, offering advanced capabilities for cutting and shaping.

Key Features:

- 5-Axis Flexibility: This feature allows the machine to cut stone from multiple angles, making it perfect for intricate shapes and curved edges.

- Material Compatibility: Works with granite, marble, and quartz.

- Advanced Software: The machine comes with user-friendly software to create customized cutting paths.

- High-Speed Cutting: It cuts quickly without sacrificing accuracy, which is ideal for large production runs.

Applications: This machine is perfect for stone processing plants, countertop production, and wall profiling projects.

CNC Stone Engraving Machine

For detailed engraving and carving, the CNC stone engraving machine is a top choice. This machine can execute fine etchings and intricate designs on various stone types, perfect for creating memorials, custom signage, and artistic pieces.

Key Features:

- High-Precision Engraving: It achieves sharp, detailed engravings.

- Wide Material Compatibility: Works with granite, marble, and softer stones like limestone.

- Adjustable Settings: You can modify engraving depths and speeds to suit different projects.

Applications: This machine is ideal for monument engraving, custom signage, and decorative stone designs.

CNC Stone Cutting Router

The CNC stone cutting router is a flexible machine that can both cut and engrave stone. It’s perfect for businesses that need a multi-functional machine that can handle large projects and fine detailing.

Key Features:

- Multi-Purpose: Suitable for both cutting and engraving tasks.

- Multiple Axes: Some models feature 3 to 5-axis capabilities for greater flexibility in shaping stone.

- Durability: Built to last, even under heavy use.

Applications: This machine is commonly used for countertop fabrication, tile production, and decorative stone carving.

Stone CNC Router with Rotary Axis

CNC Bridge Saw for Stone Cutting

The CNC bridge saw for stone cutting is a robust machine that handles large slabs of stone efficiently. It’s designed for businesses that need to cut large quantities of stone quickly without compromising on precision.

Key Features:

- Large Cutting Capacity: Handles large slabs of stone with ease.

- Multiple Functions: Suitable for straight, angled, and curved cuts.

- Heavy-Duty Performance: Built to endure tough materials like granite and marble.

Applications: This machine is perfect for fabricating kitchen countertops, producing large wall cladding pieces, and manufacturing stone monuments.

Why Choose IGOLDENCNC?

At IGOLDENCNC, we provide high-quality CNC machines for stone cutting that help businesses achieve precision, efficiency, and flexibility. Here’s why you should choose us:

- High-Quality Craftsmanship: We build machines to last, ensuring reliable performance for many years.

- Customization: Our machines can be tailored to meet your specific needs, whether you need a machine for small-scale decorative work or large-scale industrial production.

- Global Reach: We serve customers worldwide, offering excellent support and service.

- Competitive Prices: Our prices are among the most competitive in the market, ensuring you get the best value for your investment.

If you’re in the market for a CNC machine for stone cutting, IGOLDENCNC has the perfect solution for you. We offer a wide selection of CNC machines that cater to different stone cutting applications. Contact us today for the latest prices and learn how our machines can help you streamline your stone processing operations.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.