Blog

Top 5-Axis CNC granite cutting machines for precision stone cutting

Welcome to the future of stone cutting with our 5-Axis CNC granite cutting machines. Designed for precision and efficiency, these advanced tools revolutionize how you cut granite and other materials. Discover how our technology can enhance your projects, providing superior accuracy and speed while minimizing waste. Explore the ultimate solution for all your stone cutting needs

What is a 5-Axis CNC Granite Cutting Machine?

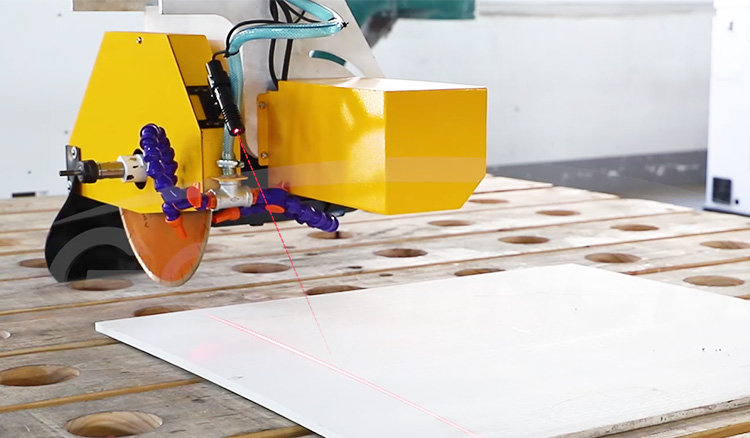

The 5-axis CNC granite cutting machine is a computer-controlled cutting tool that can move a cutting head or tool in five different axes simultaneously,and can perform 360° infrared fully automatic cutting. This allows for more complex and precise cuts compared to traditional 3-axis machines, which can only move along the X, Y, and Z axes.

In the context of granite other stone cutting, a 5-axis CNC granite cutting machine can cut intricate shapes, curves, and angles that would be difficult or impossible to achieve with manual cutting methods or simpler machines. This makes it ideal for creating custom countertops, architectural features, and detailed stone carvings.

Key Features of a 5-Axis CNC Granite Cutting Machine

- Precision Cutting: The ability to move in five axes allows for highly accurate and intricate cuts, reducing waste and ensuring that each piece of granite is cut to exact specifications.

- Versatility: These machines can handle a wide range of materials in addition to granite, including marble, quartz, and other natural stones.

- Automated Operation: With CNC (Computer Numerical Control), the machine can be programmed to perform complex cuts automatically, reducing the need for manual labor and minimizing human error.

- Increased Efficiency: By automating the cutting process and allowing for more complex cuts, 5-axis CNC granite cutting machines can significantly speed up production times.

- Durability: Built to handle tough materials like granite, these machines are designed for long-term use and can withstand the rigors of industrial applications.

How Does a 5-Axis CNC Granite Cutting Machine Work?

The cnc machine granite operates by using a combination of rotary and linear motions. Here’s a breakdown of how each axis works:

- X-axis: Moves the cutting tool horizontally, left to right.

- Y-axis: Moves the tool forward and backward.

- Z-axis: Moves the tool up and down.

- A-axis: Rotates the tool around the X-axis.

- B-axis: Rotates the tool around the Y-axis.

By working in these five dimensions, the machine can cut granite into almost any shape or design. The CNC controller interprets a digital design file, often created in CAD (Computer-Aided Design) software, and translates it into precise movements of the cutting tool.

Benefits of Using a 5-Axis CNC Granite Cutting Machine

1. Enhanced Precision

One of the primary benefits of using a 5-axis CNC machine is the precision it offers. The ability to move in five directions simultaneously allows for more complex and accurate cuts, which is especially important when working with expensive materials like granite.

2. Increased Productivity

Because these machines can perform multiple operations in a single setup, they can significantly reduce production time. This is particularly beneficial for industries that need to produce large quantities of granite products quickly and efficiently.

3. Reduced Waste

With precise cuts and automated operation, cnc machine for granite help minimize material waste. This is not only cost-effective but also environmentally friendly, as it reduces the amount of granite that ends up in landfills.

4. Versatility

These machines are not limited to cutting granite. They can also be used to cut other types of stone, as well as metals, plastics, and composites. This makes them a versatile tool for a wide range of industries, from construction to aerospace.

5. Lower Labor Costs

By automating the cutting process, 5-axis CNC granite cutting machines reduce the need for skilled labor. This can lead to significant cost savings, especially for businesses that need to produce large volumes of granite products.

Applications of Granite cnc machine Machines

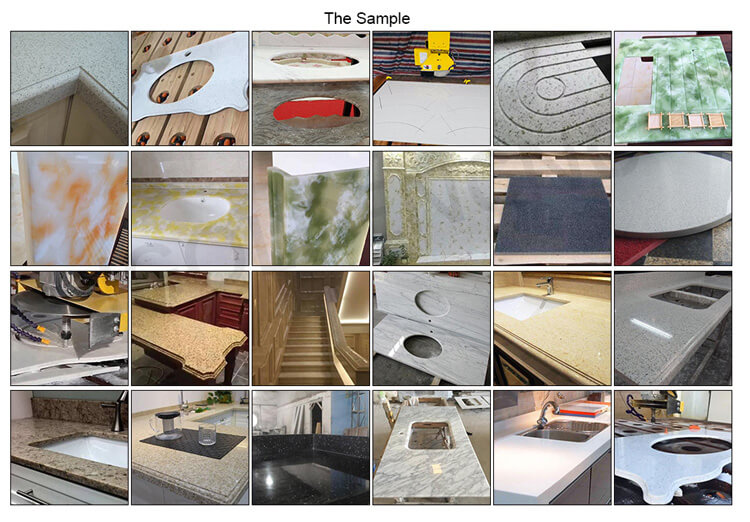

1. Countertop Fabrication

One of the most common applications for 5-axis CNC granite cutting machine is in the fabrication of kitchen and bathroom countertops. The precision of these machines allows for custom shapes, cutouts for sinks, and intricate edge profiles.

2. Architectural Features

From columns and balustrades to intricate stone carvings, granite cnc machines are often used to create architectural features that require a high level of detail and precision.

3. Monuments and Memorials

Granite is a popular material for monuments and memorials due to its durability and aesthetic appeal. 5-axis CNC granite cutting machines can create detailed engravings and custom shapes, making them ideal for this application.

4. Interior Design

High-end interior designers often use 5-axis CNC granite cutting machines to create custom stone features, such as fireplace surrounds, wall panels, and flooring inlays.

5. Industrial Applications

In addition to decorative and architectural uses, 5-axis CNC granite cutting machines are also used in industrial applications where precision cutting of hard materials is required, such as in the aerospace and automotive industries.

Factors to Consider When Choosing a 5-Axis CNC Granite Cutting Machine

When selecting a 5-axis CNC granite cutting machine for your business, there are several factors to consider:

1. Machine Size

The size of the machine will determine the size of the granite slabs you can work with. Make sure to choose a machine that can accommodate the dimensions of the materials you plan to cut.

2. Cutting Speed

Different machines have different cutting speeds, which can affect production times. If you need to produce large quantities of granite products quickly, look for a machine with a high cutting speed.

3. Software Compatibility

Most 5-axis CNC granite cutting machines use CAD/CAM software to create and execute cutting programs. Ensure that the machine you choose is compatible with the software you use or plan to use.

4. Durability and Maintenance

Granite is a tough material, so you’ll want a machine that is built to last. Look for machines made from high-quality materials and with a reputation for durability. Also, consider the maintenance requirements of the machine.

5. Cost

While 5-axis CNC granite cutting machines can be a significant investment, they can also lead to long-term cost savings by reducing waste and labor costs. Be sure to factor in the potential return on investment when considering the cost.

Frequently Asked Questions (FAQ)

1. What is the difference between a 3-axis and a 5-axis CNC granite cutting machine?

The 3-axis CNC machine can only move the cutting tool along the X, Y, and Z axes, while a 5-axis CNC granite cutting machine can move along two additional axes (A and B), allowing for more complex and precise cuts.

2. Can a 5-axis CNC granite cutting machine cut other materials besides granite?

Yes, 5-axis CNC granite cutting machines can cut a wide range of materials, including marble, quartz, metals, plastics, and composites.

3. How much does a 5-axis CNC granite cutting machine cost?

The cost of a 5-axis CNC granite cutting machine can vary widely depending on the size, features, and brand. Prices typically range from $100,000 to $500,000 or more.

4. Is it difficult to operate a 5-axis CNC granite cutting machine?

While 5-axis CNC granite cutting machines are more complex than 3-axis machines, they are typically operated using CAD/CAM software, which simplifies the process. However, proper training is essential to ensure safe and efficient operation.

5. How long does it take to cut a slab of granite with a 5-axis CNC granite cutting machine?

The cutting time depends on the complexity of the design and the size of the slab. Simple cuts can take just a few minutes, while more intricate designs may take several hours.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.