Blog

Those CNC Stone Router Machines You Didn’t Know About

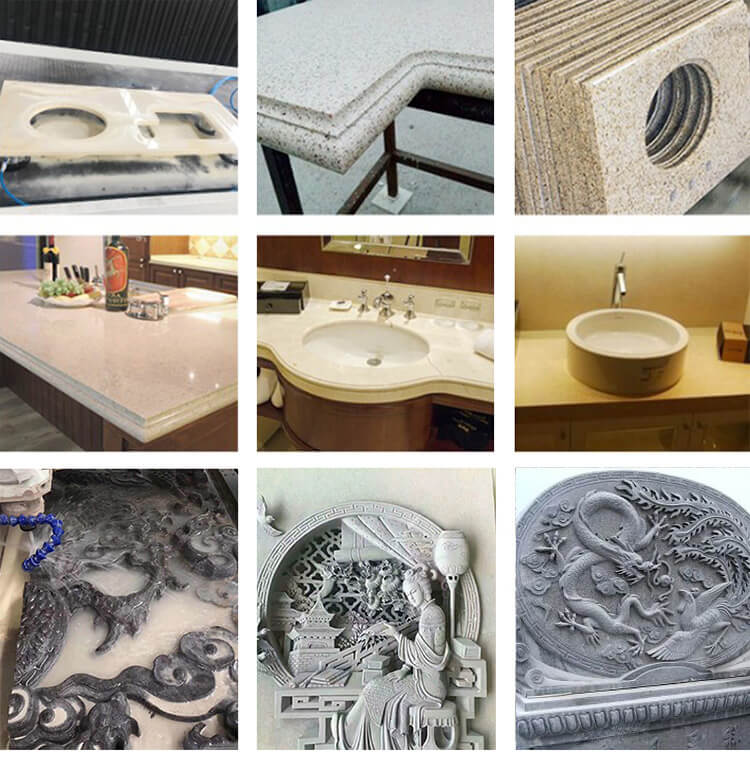

In the world of stone fabrication, precision and efficiency are key. Whether you are working with granite, marble, or limestone, a CNC stone router machine is the perfect tool to deliver high-quality, intricate designs with impeccable accuracy. However, many people still don’t realize just how versatile and powerful these machines are. In this blog, we will explore the different types of CNC stone router machines, their features, benefits, and applications, and why they are essential for modern stonework and fabrication.

What is a CNC Stone Router Machine?

CNC stone router machines are advanced computer-controlled machine used to cut, carve, and engrave stone materials with precision. The acronym “CNC” stands for Computer Numerical Control, which means the machine’s movements are governed by pre-programmed instructions from a computer, resulting in highly accurate and repeatable operations. These machines are equipped with rotary spindles and high-speed tools that can handle hard stone materials like granite, marble, quartz, and even ceramics.

CNC stone routers are available in various configurations, from basic 3-axis machines to more advanced models with 4, 5, or even 6 axes. The more axes the machine has, the greater its versatility and ability to perform complex, multi-dimensional tasks.

The Different Types of CNC Stone Router Machines

There are several different types of CNC stone router machines, each designed to cater to specific needs and tasks. Let’s take a closer look at the different types:

1. 3-Axis CNC Stone Router Machines

The 3-axis CNC stone router machine is the most common type of machine used for stone cutting and engraving. It operates along three axes — the X, Y, and Z axes — allowing for basic cutting and engraving of stone surfaces. These machines are typically used for tasks like engraving patterns, cutting stone tiles, and creating flat designs on stone slabs. While 3-axis routers are versatile, they are limited to working on a flat surface.

2. Bridge-Type CNC Stone Router Machines

Bridge-type CNC stone router machines are known for their large worktables and robust construction. They feature a fixed bridge structure that supports the cutting head, which moves along the X, Y, and Z axes. These machines are particularly useful for large-scale stone cutting and engraving projects, such as countertops, monuments, and large sculptures. Their rigid design ensures greater stability and accuracy during heavy-duty operations.

3. 5-Axis CNC Stone Router Machines

The 5-axis CNC stone router machine offers even more versatility and precision by adding another rotational axis. With this extra freedom of movement, a 5-axis machine can carve and engrave highly intricate designs, including undercuts and overhangs that would be difficult to achieve with a 3- or 4-axis machine. This type of CNC machine is ideal for professional stoneworkers and businesses that require top-level precision for creating custom stone sculptures, architectural elements, and high-end design projects.

Features of CNC Stone Router Machines

CNC stone router machines come with several features that make them indispensable for modern stonework. Here are some of the key features to consider when choosing a machine:

1. Powerful Spindle Motors

The spindle motor is one of the most important components of any CNC stone router machine. For stone applications, powerful spindle motors with high torque are essential to handle the hardness of materials like granite and marble. High-speed spindles ensure faster cutting and smoother finishes.

2. Precision Control

Precision is crucial when working with stone, and CNC machines provide this in spades. These machines use advanced control systems and feedback loops to ensure that the cutting tool follows the exact path specified in the design file, whether it’s a simple engraving or an intricate sculpture.

3. Advanced Software Integration

CNC stone router machines are typically integrated with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, which allows users to design and modify stonework before sending it to the machine for execution. The software ensures that the design is translated into machine code with accuracy, enabling flawless execution.

4. Tool Changing Capabilities

Many advanced CNC stone routers come with automatic tool changers (ATC) that allow for quick and seamless switching between tools without manual intervention. This feature is particularly beneficial when working with different materials or performing multi-step operations, such as engraving, cutting, and polishing.

5. Multi-Axis Movement

As mentioned earlier, the number of axes a machine has impacts its ability to perform complex operations. 3-axis machines are limited to basic movements along flat surfaces, while 5-axis and higher machines offer unparalleled flexibility for creating intricate 3D designs and sculptures.

Benefits of CNC Stone Router Machines

Using a CNC stone router comes with numerous advantages, particularly in terms of precision, speed, and efficiency. Let’s take a look at some of the key benefits:

1. Unmatched Precision

CNC machines offer precision that is difficult to achieve manually. Whether you are engraving detailed patterns, cutting stone slabs, or carving sculptures, CNC stone routers ensure accuracy with every cut. This level of precision allows businesses to create high-quality products consistently, which is crucial for gaining customer satisfaction and trust.

2. Faster Production Time

CNC stone routers drastically reduce the time needed to complete stone projects. Unlike manual carving or cutting, which requires a significant amount of time and effort, CNC routers can complete tasks quickly and efficiently, increasing overall production capacity. This is especially important for businesses that deal with high volumes of orders or complex designs.

3. Consistency in Quality

Once a design is programmed into the CNC machine, it can be replicated as many times as needed with the same quality and precision. This consistency ensures that large batches of stone products, such as tiles, panels, or gravestones, are made to identical specifications.

4. Versatility in Applications

Whether you’re cutting stone for interior decoration, carving intricate patterns, or producing functional pieces like countertops or monuments, CNC stone routers are versatile machines that can handle a wide range of tasks. From simple engraving to complex 3D sculptures, these machines can handle almost any stonework project with ease.

5. Reducing Labor Costs

Manual stonework can be labor-intensive and requires skilled artisans to produce quality results. CNC stone routers reduce the need for specialized labor, as the machine can perform the tasks that would typically take a team of workers. This helps businesses save on labor costs and allocate resources to other areas of production.

Applications of Stone CNC Router

CNC stone router machines are widely used across various industries that rely on stonework. Here are some common applications:

1. Monument and Gravestone Manufacturing

CNC stone routers are commonly used for engraving and carving gravestones, memorial plaques, and monuments. The machines allow for intricate text and design engraving with exceptional detail, providing a personalized touch for memorialization.

2. Stone Furniture and Countertops

CNC machines are ideal for creating custom stone countertops and furniture pieces. The precision cutting capabilities allow for smooth, clean edges and tailored designs, making them popular for kitchens, bathrooms, and commercial spaces.

3. Architectural Stonework

CNC stone routers are essential in the creation of custom architectural stonework, such as moldings, columns, and decorative wall panels. These machines enable stoneworkers to replicate traditional designs or create entirely new styles with ease.

4. Art and Sculpture

CNC stone routers are also used by artists and sculptors to carve detailed, large-scale sculptures in stone. Whether it’s abstract art or realistic figures, these machines allow artists to create complex shapes and details that would be difficult to achieve with manual tools.

Conclusion

CNC stone router machines are transforming the stone fabrication industry by enabling businesses to achieve high levels of precision, speed, and versatility. From cutting granite slabs to engraving intricate designs on marble and other stone materials, these machines are essential for professional stoneworkers, architects, and artists.

With a wide range of options, from 3-axis machines to advanced 5-axis systems, there’s a CNC stone router machine for every need. By investing in a CNC stone router, businesses can increase productivity, reduce labor costs, and consistently produce high-quality stone products. Whether you’re in the monument-making business or the stone sculpture industry, these machines offer the perfect solution for all your stone cutting, carving, and engraving needs.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.