Blog

Stone Engraving CNC Router for Detailed Stone Carving Projects

The Shift to Automation in Stone Engraving

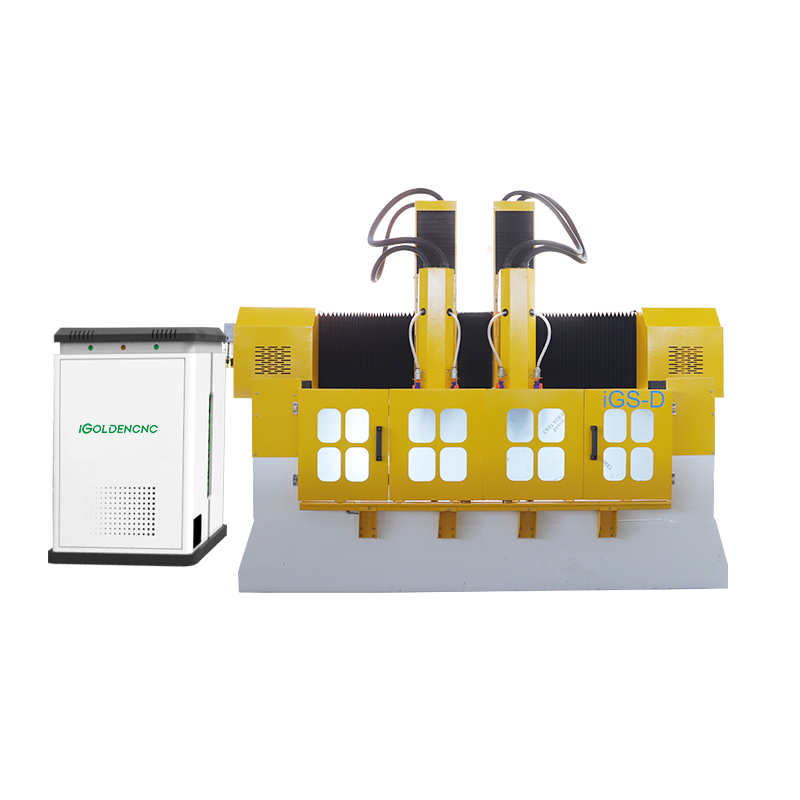

stone engraving CNC router is a computer-controlled machine designed specifically to carve, engrave, or mill stone materials with high precision. These routers use rotary or oscillating tools to carve through a range of stone types, including marble, granite, limestone, and soapstone.

Stone engraving, once dominated by the hands of skilled artisans, has evolved significantly over the years. Manual carving, while deeply rooted in tradition, comes with its own set of challenges: the time required for precision, the physical toll on the artisan, and the risk of errors that could mar a design. Enter the CNC stone engraving machine—a tool that combines artistry with automation.

The transition from hand-carving to CNC engraving has enabled artisans to cut stone with unmatched accuracy, significantly reducing production time. This shift has empowered small businesses and large manufacturers to scale their operations without compromising the quality of their work. What makes CNC technology so powerful is its ability to translate a digital design into a physical object with extreme precision. This means artists can focus more on creativity, while the machine handles the intricacies of execution.

Why Choose a CNC Stone Carving Machine?

The stone engraving CNC router is a versatile tool used in various industries. Its precision, speed, and ability to work with multiple materials make it an invaluable asset for a wide range of stone engraving projects. With the myriad of options available in the market, it’s essential to understand what sets CNC stone engraving apart from traditional methods and other machinery options. Here’s why it’s rapidly becoming the go-to solution for stone projects:

1. Precision Beyond Human Ability

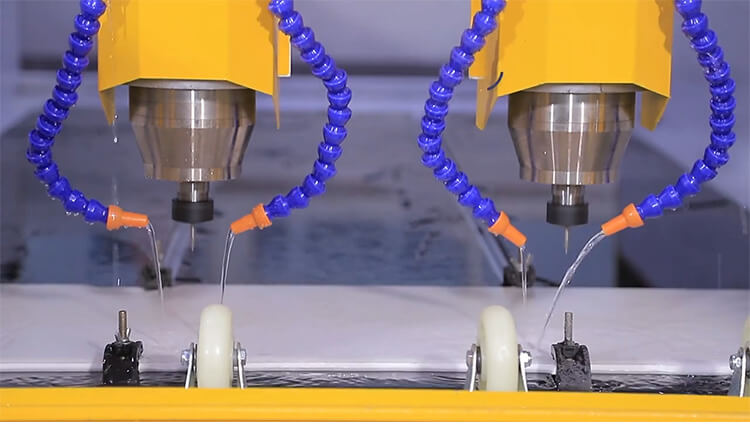

One of the most significant advantages of CNC stone engraving is the unmatched precision it offers. Where human hands can only go so far, a CNC machine can engrave incredibly fine details with perfect repeatability. Whether it’s carving a delicate pattern or engraving text, the machine can replicate the design flawlessly, ensuring that each piece meets the exact specifications.

2. Time Efficiency

Carving stone by hand is not only labor-intensive but also time-consuming. A skilled artisan can spend hours, days, or even weeks on a single piece. With CNC stone engraving, the process becomes much faster. The machine can run continuously, churning out intricate designs in a fraction of the time. This increased speed allows businesses to handle larger volumes of work without sacrificing quality.

3. Versatility for Various Stone Types

Different stones come with their own challenges. Hard materials like granite require more force, while softer stones like marble may need different handling techniques. CNC stone engraving machines are versatile, capable of working with a range of stone materials—each machine is customizable with different tool sets designed to handle the specific needs of the material. This versatility makes CNC engraving a practical choice for any stoneworking business or artist.

4. Cost-Effective in the Long Run

While the initial investment in a CNC stone engraving machine may be significant, the return on investment (ROI) is compelling. The efficiency, speed, and precision that CNC engraving offers can drastically reduce labor costs. Additionally, the reduced likelihood of errors means less waste and fewer resources spent on correcting mistakes. In the long run, this makes CNC engraving a cost-effective solution for businesses and individual artisans alike.

Types of Stone Engraving Projects Perfect for CNC Machines

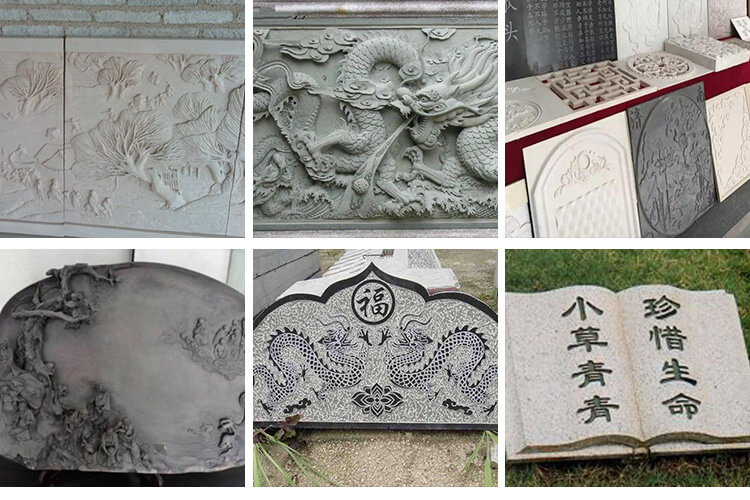

CNC stone engraving machines are perfect for a wide variety of stone projects. From decorative carvings to industrial applications, these machines can tackle any task with precision and efficiency.

Monuments and Gravestones

Perhaps one of the most recognized uses of CNC stone engraving is in the creation of monuments, gravestones, and memorial plaques. These products often require detailed engraving, from intricate floral designs to personalized inscriptions. Using a CNC stone engraving machine, memorial makers can create complex designs consistently across multiple projects. Whether it’s a simple text or a full-scale, highly detailed design, the CNC machine can provide the necessary precision, making it easier to meet client expectations.

Architectural Detailing

For architectural projects, stone is often used as a foundational material in structures like columns, arches, and facades. CNC stone engraving machines are ideal for these projects, offering the ability to carve detailed and unique elements that enhance the aesthetic value of the structure. Custom designs, logos, and intricate carvings can be precisely cut into stone, adding a personal touch to public and private buildings alike.

Stone Signage and Branding

Incorporating stone signage into a business or property adds both durability and elegance. With CNC stone engraving, businesses can create professional signage with logos, names, and branding messages. These engraved stone signs are not only visually appealing but also resistant to the elements, making them ideal for outdoor placement.

Artistic Sculptures and Custom Pieces

Artists who specialize in stone have also embraced CNC engraving machines for their ability to create highly detailed and intricate sculptures. From classical busts to contemporary designs, CNC machines allow artists to explore new dimensions of creativity. These machines can also handle the fine details that are difficult to achieve by hand, ensuring that sculptures maintain their artistic integrity throughout the carving process.

Home Décor and Custom Gifts

Stone engraving isn’t limited to large-scale projects. Many artisans use CNC stone engraving machines to produce smaller, customized items like stone coasters, decorative pieces, and personalized gifts. Whether for home décor or corporate giveaways, CNC machines provide the precision necessary for intricate designs on smaller stone surfaces, adding a unique, personal touch.

How to Choose the Right CNC Stone Engraving Machine

Selecting the right CNC stone engraving machine for your projects depends on several factors, from the type of work you plan to do to your budget. Here are a few key points to consider:

Machine Size and Capacity

Depending on your business or artistic needs, the size of the machine is an important factor. Larger machines can handle bigger slabs of stone, while smaller ones may be more suited for intricate, detailed work on smaller pieces. Consider your typical project sizes and select a machine that will meet those requirements.

Tool Compatibility

Different types of stone require different tools for engraving. For example, harder materials like granite will require specialized diamond tools. Look for a machine that offers flexibility in terms of tooling, so you can easily switch between different materials and techniques.

Software Integration

Most CNC stone engraving machines come with their own software, but compatibility with popular CAD software like AutoCAD or Rhino can significantly improve your workflow. Be sure the machine’s software supports the designs you wish to create and offers intuitive controls for easy programming.

Support and Warranty

Given the investment in a CNC engraving machine, it’s essential to choose a manufacturer that offers strong customer support and a reliable warranty. Having access to technical support when issues arise can prevent costly downtime and ensure the machine remains operational for years to come.

Conclusion: Elevate Your Stone Engraving Projects

CNC stone engraving machines have revolutionized the way stone carving is done. Offering unmatched precision, speed, and versatility, these machines have become indispensable tools for artisans, businesses, and monument makers alike. Whether you’re crafting detailed memorials, architectural elements, or artistic sculptures, the power of CNC technology allows for designs that were once impossible to achieve manually.

By embracing CNC stone engraving, you not only enhance your creative capabilities but also increase your efficiency and profitability. The future of stone carving is bright, and CNC engraving is at the forefront of this evolution—empowering artists and businesses to carve out their unique space in the world of stone craftsmanship.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.