Blog

Stone CNC Machine for Perfect Finishes

In the world of stone carving and machining, precision is everything. Whether it’s creating intricate sculptures, countertops, or architectural features, a stone CNC machine is the key to achieving flawless results. These machines bring cutting-edge technology into traditional stonework, making processes faster, more efficient, and highly accurate. Using a stone CNC machine can improve the quality of your work, and investing in a CNC machine can greatly improve your business.

What is a Stone CNC Machine?

Stone CNC machine is a computer-controlled system that is designed to cut, carve, and engrave stone with precision. CNC stands for Computer Numerical Control, meaning the machine follows precise instructions given by computer software to perform specific tasks. This automation allows for a level of accuracy that manual methods simply cannot match.

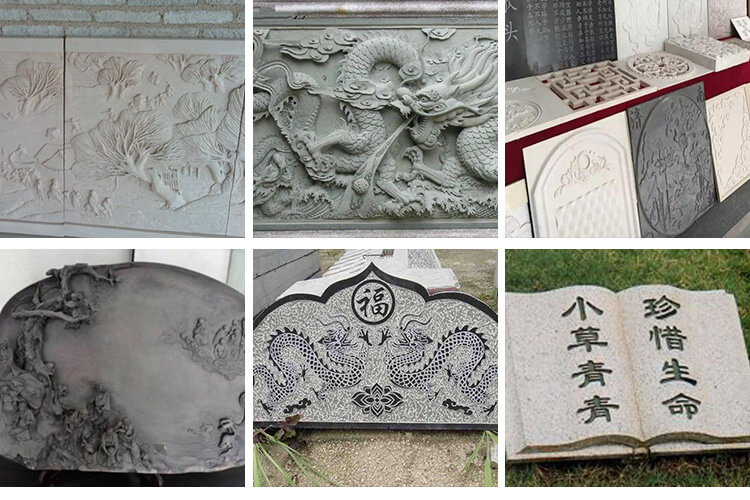

Stone CNC machines come in various types, including routers and mills, with some models offering 3, 4, or even 5-axis capabilities. These machines can work with a variety of materials, including granite, marble, limestone, and even synthetic stones, to create everything from simple engravings to complex, three-dimensional sculptures.

The Advantages of Using a Stone CNC Machine

1. Precision and Accuracy

The most obvious benefit of using a stone CNC machine is the precision it offers. Manual carving, engraving, or cutting stone can be incredibly challenging and time-consuming, especially when aiming for high levels of detail. With a CNC machine, your designs are created with millimeter accuracy, ensuring consistent results with every project. This is especially useful for businesses that require repetitive tasks, such as cutting countertops or engraving gravestones.

The ability to work with complex 3D designs also sets CNC machines apart from traditional methods. Whether you’re creating intricate patterns or highly detailed stone sculptures, the CNC machine can bring your vision to life without compromising on quality.

2. Increased Efficiency and Productivity

The automation of a stone CNC machine means faster production times and higher output. Once you input your design into the system, the machine does the rest. This significantly reduces the time spent on manual labor, allowing your business to take on more projects and increase revenue.

Moreover, CNC machines often operate 24/7 with minimal supervision. Once set up, they can continue to work on multiple pieces simultaneously, maximizing productivity and keeping costs low.

3. Cost-Effective in the Long Run

While the initial cost of purchasing a stone CNC machine might seem high, it is a sound investment for businesses looking to scale. The automation process reduces labor costs, lowers material wastage, and improves production efficiency. Over time, these savings will far outweigh the initial purchase price.

Additionally, the precision of CNC machines helps minimize errors during production. With less rework and waste, you’ll save money in the long term. The machines also require minimal maintenance, further reducing operational costs.

4. Versatility Across Various Applications

Stone CNC machines are incredibly versatile, making them useful in a variety of industries. Whether you’re in the construction, monument, or artistic stone carving sector, these machines can handle it all. Some of the most common applications include:

- Monument and Tombstone Engraving: Whether it’s a traditional or contemporary design, CNC machines offer the precision needed for memorial stone engraving.

- Countertop Fabrication: With the ability to cut and shape granite, marble, and other hard stones, CNC machines are perfect for creating countertops with intricate designs.

- Architectural Features: From columns to ornate stone carvings, CNC machines can carve intricate architectural features that are both functional and aesthetically pleasing.

- Sculpture and Artwork: Artists and sculptors can use CNC machines to create highly detailed sculptures and relief carvings, offering a level of artistry that manual tools simply cannot replicate.

Key Features to Look for in a Stone CNC Machine

When selecting a stone CNC machine, it’s crucial to evaluate several factors to ensure you choose the right one for your business. The number of axes is an essential consideration. Stone CNC machines come in 3-axis, 4-axis, or 5-axis CNC stone machining center. A 3-axis machine is suitable for basic cutting, engraving, and carving tasks. For more complex shapes and deeper carvings, a 4-axis machine offers additional rotational capabilities. However, if you’re looking for maximum flexibility and the ability to work on all sides of the stone, a 5-axis machine is ideal for creating intricate 3D shapes with precision.

Additionally, the software compatibility of the machine plays a significant role in its functionality. Machines that work with popular CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) programs, such as AutoCAD, Rhino, and Mastercam, allow for seamless design-to-production workflows, ensuring the accuracy of your designs. The quality of cutting tools is also vital for achieving smooth, precise cuts. Look for machines that are compatible with diamond-tipped tools to guarantee high-quality finishes on your stone materials.

Machine Stability and Durability for High-Precision Work

The stability of the CNC machine is critical for precise stone cutting and carving. A solid, stable frame made from durable materials like steel or cast iron ensures minimal vibration during operation. This reduces errors and ensures smoother, more accurate cuts. Stone CNC machines are subjected to significant forces during operation, so choosing a machine with a sturdy construction will not only enhance cutting precision but also extend the longevity of the machine. Machine stability is a key factor in producing consistent, high-quality results across various stone projects.

Maintenance and Care for Your CNC Stone Machine

While stone CNC machines are generally low-maintenance, it’s important to follow a regular maintenance routine to ensure longevity and optimal performance. Here are some tips:

- Regular Cleaning: Stone cutting generates dust and debris, which can clog up the machine. Clean the machine regularly to keep it running smoothly.

- Lubrication: Ensure the moving parts of the machine are well-lubricated to prevent friction and wear over time.

- Check for Wear and Tear: Regularly inspect the machine for any signs of wear, especially on cutting tools. Replacing worn-out parts will ensure the machine continues to produce high-quality results.

- Calibration: Periodically recalibrate the CNC machine to ensure it maintains its accuracy and precision.

Conclusion

Stone CNC machine can revolutionize the way you approach stone carving, cutting, and engraving. The precision, efficiency, and versatility it offers can drastically improve your production capabilities and the quality of your work. Whether you’re creating complex sculptures, countertops, or architectural features, a CNC machine can help you achieve perfect finishes with minimal effort.

If you’re in the market for a stone CNC machine, it’s essential to choose a machine that suits your specific needs and budget. Look for key features like the number of axes, software compatibility, and cutting tools to make the best decision for your business.

By incorporating a stone CNC machine into your production process, you can stay ahead of the competition, improve your workflow, and deliver top-notch stonework to your clients every time.

FAQ

1. How accurate are stone CNC machines?

Stone CNC machines are incredibly accurate, capable of producing cuts and carvings down to millimeter precision. This level of detail ensures high-quality results, especially for intricate designs.

2. What types of stone can a CNC machine cut?

CNC machines can cut a variety of stones, including granite, marble, limestone, and sandstone. They are also capable of working with synthetic stones and composites.

3. How long does it take to complete a project with a CNC stone machine?

The time required for a project depends on its complexity and size. However, CNC machines can complete tasks much faster than manual methods, improving production time significantly.

4. Do CNC stone machines require a lot of maintenance?

CNC stone machines are relatively low-maintenance. Regular cleaning, lubrication, and tool replacement are all that’s needed to ensure the machine runs efficiently.

5. Can I use the same CNC machine for both cutting and engraving stone?

Yes, many stone CNC machines are versatile enough to handle both cutting and engraving tasks. Ensure that your machine has the appropriate tooling and software to perform both functions.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.