Blog

Innovative CNC Stone Cutting for Accurate

Stone cutting has evolved from traditional methods into an era of precision and efficiency, thanks to CNC stone cutting machines. With unmatched accuracy, CNC technology has become the preferred choice for architects, designers, and fabricators. This blog explores the benefits, applications, and features of CNC stone cutting, showcasing why it’s a game-changer for the stone industry.

What is CNC Stone Cutting and how does it work?

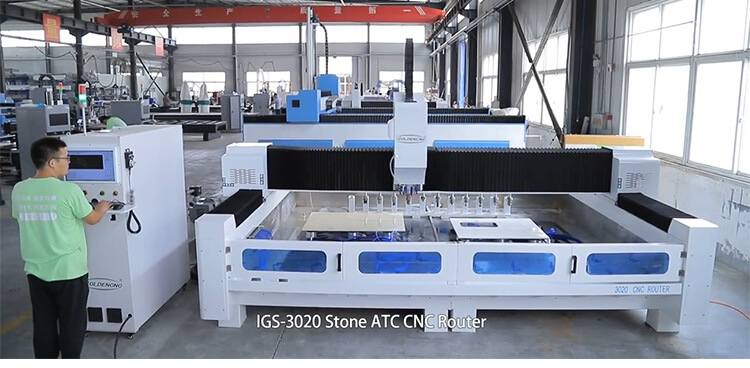

CNC stone cutting & polishing is used for cabinets artificial stone, quartz stone, granite, marble carving, cutting, polishing, drilling, engraving. CNC stone cutting involves the use of automated machines to shape, carve, and engrave stone materials. These machines execute pre-programmed designs with exceptional precision, reducing manual errors.

CNC stone cutting is a process that has been applied to cutting technologies for many different materials, including woods, metals, and plastics. A CNC stone engraving machine operates by engraving the stone with a diamond-tipped blade or a laser beam, which removes small chips of stone until the desired shape or pattern is achieved. The cutter head moves in three dimensions, allowing for more complex shapes to be carved out of the stone. It also produces a high-quality surface finish.

Advantages and Disadvantages of CNC Stone Cutter

Advantages of CNC Stone Cutter

CNC stone cutting offers remarkable speed and efficiency, allowing for the processing of large volumes of stone in minimal time. This capability is particularly advantageous for high-volume or large-scale projects, ensuring timely production. Additionally, CNC machines provide uniformity and precision, making them ideal for projects requiring exact specifications or intricate designs. Although the initial investment in CNC equipment can be high, the cost-effectiveness of these machines becomes evident over time. By reducing manual labor and increasing productivity, businesses can lower long-term operational costs. Moreover, CNC machines enable the creation of complex designs that are challenging to achieve through traditional methods, offering greater design flexibility.

Disadvantages of CNC Stone Cutter

Despite its benefits, CNC stone machine has notable drawbacks. The high initial investment for purchasing, installing, and maintaining CNC equipment can be a barrier for small businesses or projects with limited budgets. Additionally, operating these machines requires technical expertise and training in both machine technology and the software that powers their programming. Another downside is the loss of artisan touch, as the precision of CNC machines may lack the personal or artistic nuances typically associated with hand-carved work.

Applications of CNC Stone Machines

Construction and Architecture

CNC machines are used to create stone facades, intricate columns, and precise flooring patterns. Their ability to handle complex geometries is ideal for modern architectural designs.

Memorial and Monument Industry

Gravestones and memorial plaques often require detailed engravings, which CNC machines can achieve with ease and uniformity.

Interior Design

CNC stone machine brings life to countertops, sinks, and decorative panels, meeting custom specifications with a flawless finish.

Art and Sculptures

Artists utilize CNC machines for intricate sculptures and detailed stone art, enabling innovative designs that would be difficult to achieve manually.

Features of Advanced CNC Stone Cutting Machines

- 5-Axis Cutting:This capability allows for cutting in complex angles and 3D geometries, expanding creative possibilities.

- High-Power Spindles:Equipped with durable spindles, CNC machines can efficiently cut through hard stones like granite and quartz.

- Integrated Software:Modern CNC machines come with intuitive software, enabling designers to create and modify patterns before execution.

- Dust and Water Control Systems:To ensure a safe and clean workspace, CNC machines are equipped with dust extraction systems and water cooling mechanisms.

Steps to Using a CNC Stone Router

- Design Creation:Begin by creating the design in CAD (Computer-Aided Design) software. This serves as the blueprint for the machine.

- Material Preparation:Secure the stone on the machine’s worktable, ensuring it is stable and properly aligned.

- Programming and Calibration:Upload the design to the CNC system and calibrate the machine to ensure precision.

- Execution:Initiate the cutting process. The CNC machine will follow the programmed path to carve or engrave the stone.

- Finishing Touches:Once the cutting is complete, remove the material for polishing or additional detailing.

CNC Stone Cutting Machine brings you money

Choosing the Right CNC Stone Cutting Machine

When selecting a CNC stone router, key factors include:

- Worktable Size: Ensure it accommodates your typical project dimensions for seamless operation.

- Software Compatibility: Opt for machines with user-friendly and versatile design software to simplify programming.

- Durability: Prioritize robust build quality, especially if working with hard stones like granite.

- Support and Maintenance: Select brands known for reliable customer support and easy maintenance.

How CNC Stone Cutting Enhances Your Home

CNC stone cutting technology provides multiple benefits for home construction and enhancement:

- Innovative Design: Computer-aided design enables endless possibilities for creating unique and intricate patterns.

- Efficient Customization: Reduced labor costs and faster processing make custom stone-cut designs more affordable and accessible.

- Streamlined Quality Production: Automated cutting ensures precise results from quarrying to installation, delivering high-quality stone with less manual effort.

Ready To Enhance Your Home With Custom Stone Features?

CNC stone router is a process that allows for more accuracy and efficiency when it comes to cutting stone. It opens up a world of possibilities for computer-aided custom design for your stone surfaces in addition to easing the stone working process during home construction.

Conclusion

CNC stone cutting machines have revolutionized the stone fabrication industry. Their precision, efficiency, and versatility make them indispensable for projects ranging from architectural masterpieces to delicate sculptures. Whether you’re a professional in the industry or an aspiring designer, CNC stone cutting can elevate your craft to the next level.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.