Blog

How to make money with cnc marble carving machine?

The CNC marble carving machine is one of the most powerful tools in the stone industry, offering precision and efficiency for intricate designs. As technology advances, many business owners are discovering new ways to leverage this machine for profit. From artistic creations to commercial projects, CNC marble carving machines are transforming how stonework is done, providing new revenue streams for entrepreneurs. In this blog, we will explore how you can use a CNC marble carving machine to make money, covering essential aspects like market opportunities, techniques, and tips for maximizing profitability.

Understanding the CNC Marble Carving Machine

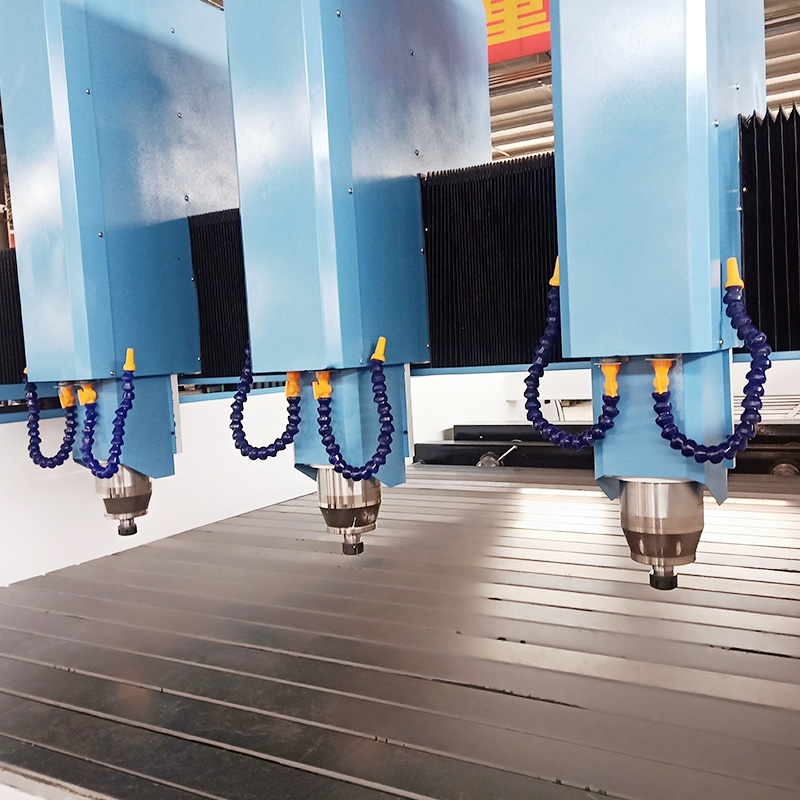

Before diving into ways to monetize your CNC marble carving machine, it’s essential to understand the capabilities and applications of this powerful tool. A CNC (Computer Numerical Control) machine operates through programmed instructions, allowing it to carve, engrave, and cut marble with precision. Unlike manual carving, which can be time-consuming and inconsistent, a CNC marble carving machine delivers perfect results every time.

Key Features of CNC Marble Carving Machines:

- High Precision: Capable of intricate detailing and accurate cuts on marble surfaces.

- Automation: Reduces the need for manual labor and improves efficiency.

- Versatility: Suitable for a wide range of designs, from simple patterns to complex 3D sculptures.

Market Opportunities for CNC Marble Carving

Once you understand the potential of your CNC marble carving machine, it’s time to explore different markets where you can generate income. Here are some of the most profitable avenues for using a CNC marble carving machine:

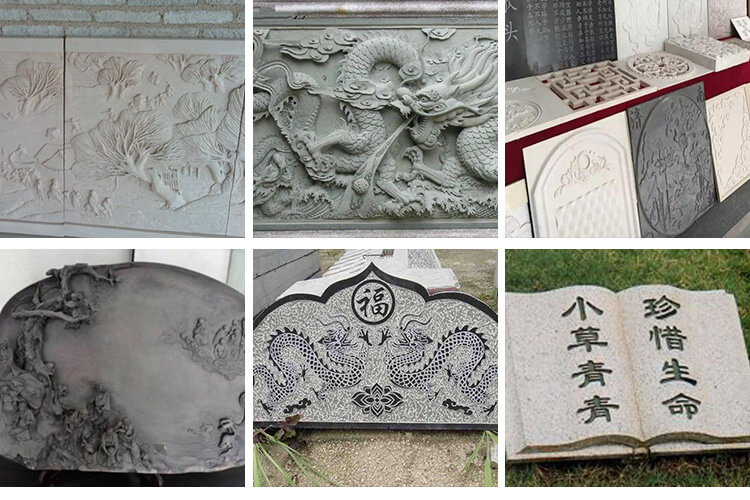

a) Customized Marble Monuments and Tombstones

The demand for customized memorial products, such as tombstones and monuments, is always present. People frequently seek unique and personal designs for their loved ones. With a CNC marble carving machine, you can offer high-quality, custom engraving services for memorial stones.

How to get started:

- Offer personalized engravings and carvings, such as names, dates, quotes, or religious symbols.

- Focus on creating intricate designs that traditional methods cannot achieve.

- Collaborate with funeral homes or cemeteries to establish a reliable supply chain.

b) Marble Sculptures and Artworks

The art world presents a lucrative opportunity for CNC marble carvers. Artists and collectors value marble sculptures, which can be used for home décor, public installations, or galleries. With the precision of a CNC machine, you can create highly detailed sculptures that would be challenging to produce by hand.

How to get started:

- Learn 3D design software such as AutoCAD or Rhino to create detailed sculptures.

- Develop your own signature style to stand out in the market.

- Partner with galleries or art exhibitions to showcase and sell your creations.

c) Marble Signage and Engraving for Businesses

Businesses often need custom signage for their storefronts, lobbies, or corporate offices. A CNC marble carving machine can create sophisticated, long-lasting signage with precise logos, company names, and other essential details. This can be a profitable niche, especially in high-end markets or commercial sectors like hotels, restaurants, and law firms.

How to get started:

- Offer services for creating engraved logos, building nameplates, or directional signs.

- Market to businesses in upscale areas or those wanting to create a luxurious, professional appearance.

- Provide customized services for both indoor and outdoor signage.

d) Marble Flooring Inlays and Decorative Features

Many interior designers and homeowners look for luxurious, unique flooring options that include marble inlays or detailed borders. CNC marble carving machines can precisely cut these inlays, creating sophisticated patterns and designs for custom flooring projects.

How to get started:

- Collaborate with interior designers, architects, or flooring companies.

- Offer a variety of patterns, shapes, and styles to suit different design preferences.

- Market your services through home improvement exhibitions or online platforms.

How to Maximize Profitability with CNC Machine Marble Cutting

While the CNC marble carving machine offers many revenue-generating opportunities, maximizing its potential requires more than just having the right equipment. Here are some tips to help you increase your profitability:

a) Invest in High-Quality Materials

The quality of the marble you use directly affects the final product’s appearance and durability. To attract high-end clients, invest in premium marble that will showcase your craftsmanship. Working with superior materials can also command higher prices for your services.

b) Master Design Software

To unlock the full potential of your CNC marble carving machine, mastering design software is essential. Tools like AutoCAD, Rhino, or SolidWorks allow you to create detailed designs that the machine can execute flawlessly. The more complex and intricate your designs, the more valuable your services will be.

c) Diversify Your Offerings

Diversification is key to sustaining profitability. While focusing on one niche can be profitable, offering a broad range of services can help you capture more clients. For example, you could combine custom carvings, sculptures, signage, and flooring inlays into a single portfolio, catering to different sectors of the market.

d) Optimize Production Workflow

Efficiency is critical to maximizing profit. With CNC marble carving machines, you can increase your production speed without sacrificing quality. To streamline your workflow:

- Organize your workspace and keep tools well-maintained.

- Pre-program designs and run batch production for high-demand items.

- Keep a stock of popular designs for quicker turnaround times.

e) Target High-End Customers

High-end customers are often willing to pay premium prices for custom-made, unique pieces. Focus on providing exceptional craftsmanship and offering personalized designs. Build a reputation for delivering high-quality, exclusive work, and don’t be afraid to charge a premium for it.

Marketing Your CNC Stone Cutting Machine Business

Once you have identified your market and created a profitable workflow, the next step is marketing your CNC stone cutting machine services. Here are some effective marketing strategies:

a) Build an Online Presence

Create a professional website showcasing your work, including a portfolio of your best projects. Make sure your website is mobile-friendly, easy to navigate, and includes contact information. Also, leverage social media platforms like Instagram and Pinterest to share high-quality images of your carvings and attract a wider audience.

b) Attend Trade Shows and Exhibitions

Trade shows are an excellent way to network with potential clients and partners. Whether you’re showcasing marble sculptures or providing carving services, attending industry exhibitions can help you gain visibility and grow your customer base.

c) Offer Promotional Deals

To attract new clients, consider offering limited-time discounts or package deals. For instance, you could offer a discount on engraving services for first-time customers or bundle multiple services together for a lower price.

Conclusion: Unlocking Profit with CNC Marble Carving Machines

A CNC marble carving machine is an invaluable asset for anyone looking to venture into the stone fabrication or artistic industries. By exploring different markets, offering high-quality products, and utilizing the right tools, you can turn your CNC marble carving business into a lucrative venture. Whether you focus on custom memorials, sculptures, or business signage, the potential to make money is vast with the precision and capabilities of modern CNC machinery.

FAQ:

1. How much does a CNC marble carving machine cost?

The cost of a CNC marble carving machine varies depending on the brand, size, and features. Entry-level machines can start at around $15,000, while high-end models can reach upwards of $50,000. It’s important to choose a machine that fits your business needs and budget.

2. How difficult is it to operate a CNC marble carving machine?

Operating a CNC marble carving machine requires some training and knowledge of design software. However, most manufacturers provide training programs, and once you are familiar with the software and machine operation, it becomes relatively easy to use.

3. Can CNC marble carving machines be used for other materials besides marble?

Yes, CNC marble carving machines can often be used for other materials such as granite, limestone, and even some types of wood. However, the specific capabilities may vary depending on the machine model.

4. How long does it take to complete a marble engraving project?

The time required to complete a marble engraving project depends on the complexity and size of the design. Simple designs may take a few hours, while intricate patterns and larger sculptures may take several days.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.