Blog

High-Quality China CNC Stone Engraving Bits for Precision Carving

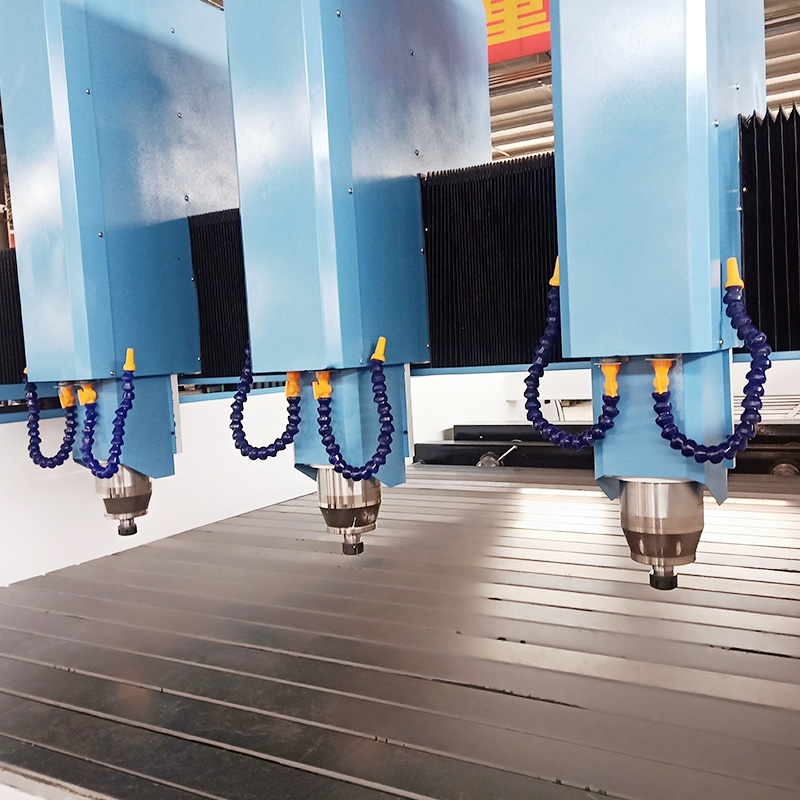

CNC (Computer Numerical Control) technology has revolutionized the stone engraving industry, offering precision, speed, and consistency that were previously unattainable through traditional methods. Whether you’re working with marble, granite, or other types of stone, the quality of your engraving tools can make all the difference. In this blog, we’ll explore the importance of using high-quality CNC stone engraving bits from China, the benefits they offer, and how they contribute to precision carving in stone.

Why Choose CNC Stone Engraving Bits from China?

China is one of the leading manufacturers of CNC tools, including high-quality stone engraving bits. With decades of expertise in manufacturing precision tools, Chinese suppliers provide CNC bits that are both affordable and reliable. Here’s why CNC stone engraving bits from China are an excellent choice:

1. Affordability

China has established itself as a global manufacturing hub, offering competitive prices due to its cost-efficient production processes. Whether you’re buying in bulk or purchasing a single tool, Chinese manufacturers are known for providing high-quality tools at a fraction of the cost compared to Western manufacturers.

2. Advanced Technology

CNC engraving bits made in China are equipped with cutting-edge technology to ensure consistent performance. The tools are made with advanced manufacturing techniques, including laser engraving, diamond coating, and high-precision grinding, which results in sharp, durable, and high-performance tools.

3. Wide Range of Options

China offers a wide variety of CNC stone engraving bits that cater to different types of stone and specific engraving needs. Whether you need a bit for fine detailing, heavy-duty carving, or intricate designs, Chinese suppliers provide multiple options to suit your requirements.

4. Quality Control Standards

Many Chinese manufacturers adhere to international quality standards, such as ISO 9001, ensuring that their CNC stone engraving bits meet global specifications. These bits are tested for precision, durability, and performance, making them reliable for both small-scale and industrial stone carving operations.

Types of CNC Stone Engraving Bits

Choosing the right engraving bit is crucial for achieving the desired result in stone carving. Different bits are suited to different types of stone, engraving techniques, and design intricacies. Here are some common types of CNC stone engraving bits available:

1. Ball Nose Bits

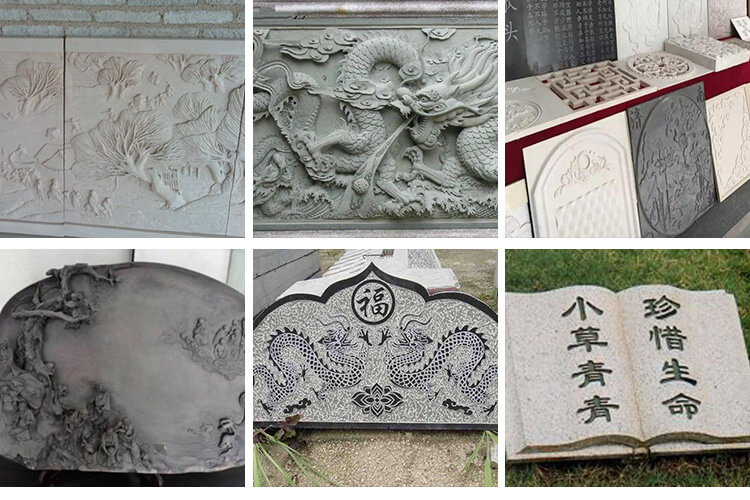

Ball nose bits are used for creating smooth, rounded shapes in stone. They’re perfect for engraving curved surfaces and intricate designs. These bits are commonly used for detailed carving and are ideal for precision stonework in statues, monuments, and decorative items.

2. Flat End Bits

Flat end bits are designed for straight, sharp engraving lines and are often used for creating geometric shapes, text, or detailed engravings. These bits provide high accuracy, especially for deep cuts and fine detailing.

3. V-Bits

V-bits are often used for engraving sharp, angular details. They are particularly useful for creating decorative borders, lettering, and symbols in stone. V-bits are versatile tools that can create both fine and deep engravings, making them an essential part of any stone engraving operation.

4. Diamond-Coated Bits

Diamond-coated CNC stone engraving bits are designed for heavy-duty carving in harder stones such as granite. The diamond coating ensures that the bit stays sharp longer and offers superior cutting power, making it ideal for precise, high-performance engraving. These bits are also highly resistant to wear and can withstand high levels of heat generated during engraving.

5. Carbide-Tipped Bits

Carbide-tipped bits offer excellent precision and durability. These bits are commonly used in CNC stone engraving machines for cutting and carving soft to medium-hard stones. The carbide tips offer superior wear resistance, ensuring that the bits maintain their sharpness for longer periods, even under continuous use.

6. Tapered Bits

Tapered bits are used for detailed engraving in narrow spaces or creating delicate designs. These bits have a gradual taper, making them ideal for deep, intricate cuts. Tapered bits can be used to create ornate designs in stone, such as jewelry, portraits, or intricate patterns.

Benefits of Using High-Quality CNC Stone Engraving Bits

When you invest in high-quality CNC stone engraving bits, you’re ensuring precision, efficiency, and durability in your stone carving projects. Here are some of the key benefits:

1. Precision and Accuracy

High-quality CNC stone engraving bits allow for precise, detailed carving with minimal error. This is especially important when working on intricate designs or when a high level of detail is required. Accurate carving leads to professional results and minimizes the need for rework.

2. Enhanced Durability

Well-made CNC stone engraving bits, particularly those with diamond coatings or carbide tips, offer longer tool life. This reduces the frequency of tool changes, allowing for continuous, high-performance work and lower long-term costs.

3. Better Finish

High-quality engraving bits provide a cleaner, smoother finish on the stone surface. This is especially important when working with decorative elements, custom stone designs, or memorial engravings, where surface quality and aesthetics are paramount.

4. Improved Cutting Speed

High-performance engraving bits enable faster cutting speeds without compromising on precision. This is critical for businesses that rely on CNC stone engraving for commercial production, where speed is important to meet deadlines and client expectations.

5. Reduced Tool Wear and Tear

Investing in premium CNC stone engraving bits helps to reduce premature wear and tear on the tools. This leads to fewer breakdowns and maintenance issues, ensuring smoother operations and less downtime.

Choosing the Right CNC Stone Engraving Bits for Your Projects

When selecting CNC stone engraving bits, consider the following factors:

1. Type of Stone

Different types of stones have different hardness levels and properties. For example, granite requires carbide-tipped or diamond-coated bits for effective carving, while softer stones like marble may only need high-speed steel bits.

2. Project Type

Depending on your project, you’ll need to select the appropriate engraving bit. Intricate designs and detailed carvings may require a finer bit, such as a ball nose or tapered bit, while larger, deeper cuts might need a flat end or V-bit.

3. Size of the Workpiece

Ensure that the engraving bits you choose are compatible with the size of your CNC machine and the workpiece. Some bits may be too large or too small for certain tasks, so consider the scale of your project before making a selection.

4. Engraving Style

Different bits offer different engraving effects. Choose a bit that matches the style you’re aiming for, whether it’s fine detailing, bold lines, or decorative patterns.

Conclusion

High-quality CNC stone engraving bits are essential tools for achieving precision, efficiency, and professional results in stone carving. By choosing the right bits for your specific stone type and project requirements, you can enhance your engraving capabilities and produce stunning, intricate designs. China has become a leading source of affordable, reliable, and high-performance CNC stone engraving bits, offering a wide range of options for professionals in the stone carving industry. Whether you’re a small-scale artisan or a large-scale manufacturer, investing in top-quality CNC stone tools will elevate your craftsmanship and ensure success in your stonework projects.

FAQ

1. What is the difference between carbide and diamond-coated CNC stone engraving bits?

Carbide bits are durable and provide excellent precision for medium-hard stones, while diamond-coated bits are best for hard stones like granite, offering superior wear resistance and longer life.

2. Can I use CNC stone engraving bits on all types of stone?

Not all engraving bits are suitable for every type of stone. It’s essential to choose the right bit based on the hardness and composition of the stone you’re working with. Softer stones like marble require different bits compared to harder stones like granite.

3. How long do CNC stone engraving bits last?

The lifespan of your CNC stone engraving bits depends on several factors, including the type of material you’re engraving, the bit’s quality, and how frequently you use them. High-quality bits, such as carbide or diamond-coated ones, tend to last longer.

4. How do I choose the right CNC stone engraving bit for my project?

When choosing an engraving bit, consider factors such as the type of stone, the level of detail required, and the specific project. For fine details, use smaller bits like ball nose or tapered bits; for larger cuts, use flat end or V-bits.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.