Blog

Tombstone CNC Machining:Versatile CNC Router for Custom Work

The Tombstone CNC Machining, also known as a stone CNC router or granite engraving machine, is a highly automated tool designed for carving and engraving various materials, including marble, granite, quartz, bluestone, jade, artificial stone, ceramic, glass, and plastic. In the world of stone processing, this machine is essential for achieving high precision and intricate designs, making it ideal not only for tombstone carving but also for a wide array of applications such as kitchen countertops, sculptures, and architectural features.

Composition of Versatile Tombstone CNC Machining

Robust Construction for Enhanced Stability

The foundation of any effective CNC machine is its construction. Our CNC tombstone machine features a lathe bed welded with thick channel steels and square tubes. This robust design is complemented by high-temperature tempering treatment and Vibrating Stress Relief (VSR) processes. These techniques effectively reduce residual stress, ensuring excellent stability and preventing deformation during prolonged use. Such stability is crucial for maintaining accuracy over long operational periods, making it ideal for intricate engraving work.

High-Speed Water Cooling Spindle

Equipped with a high-speed water cooling spindle, the tombstone cnc machining ensures consistent performance even during extended operations. The water cooling system not only keeps the spindle temperature in check but also enhances cutting efficiency. The spindle’s high performance and the machine’s advanced subdivision driver allow for precision cutting and engraving, ensuring that every detail of the design is executed flawlessly.

Efficient Cooling and Dust Management

Efficiency is further enhanced by a well-designed water tank and a double water cooling system that supports high-performance work. This dual cooling system helps maintain optimal operating temperatures while reducing wear on the machine components.

Moreover, the CNC engraving machine incorporates a special three-axis dust-proof system. This innovative feature protects the guides from dust and debris, enhancing the machine’s longevity and operational efficiency. A clean working environment is vital for achieving high-quality finishes, making this dust-proof system a significant advantage.

User-Friendly Software for Easy Operation

One of the standout features of the tombstone cnc machining is its practical and easily learned software. This software allows operators to conveniently check the moving path of the tool, adjust the processing depth of the Z-axis, and control the motor speed. Such user-friendly software is essential for both novice and experienced users, streamlining the engraving process and minimizing the learning curve.

Tombstone CNC Machining Versatile Applications

Stone Types and Materials

The CNC stone engraving machine is capable of working with various materials, including:

- Granite

- Marble

- Quartz stone

- Ceramic

- Glass

This versatility makes it suitable for a wide range of applications, including:

Kitchen and Bathroom Installations

Ideal for creating stunning kitchen countertops, shower plates, and tea trays, the CNC machine excels in precision cutting and edging. Its ability to handle materials like quartz and granite allows for elegant and durable surfaces in both residential and commercial settings.

Tombstones and Memorials

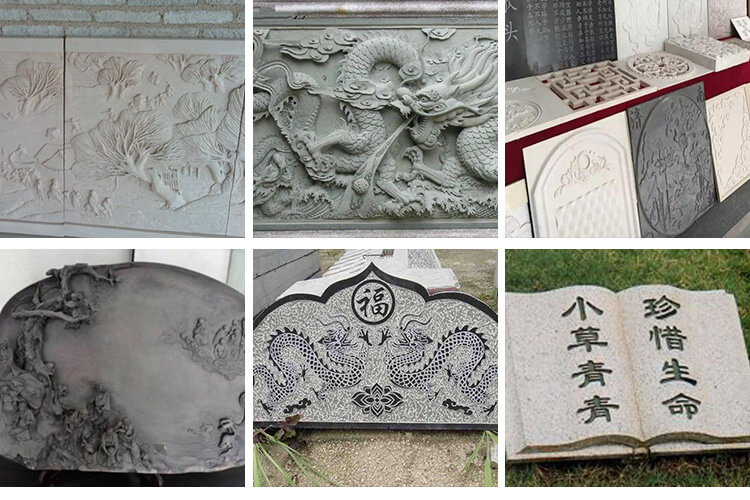

For the funeral industry, the CNC engraving machine is invaluable. It can create intricate designs and lettering on tombstones and monuments, ensuring that memorials are not only beautiful but also personalized.

Tombstone Making CNC Machine Artistic Sculptures

Whether creating bas-reliefs or more complex sculptures, the CNC machine can produce detailed artistic works. Its capabilities extend to grooving and lettering, allowing artists and craftsmen to explore their creativity fully.

Tombstone CNC Machine Construction and Industrial Applications

The machine’s utility isn’t limited to artistic endeavors. It is also suitable for industrial applications, including drilling, sanding, and edge finishing. This versatility makes it an excellent choice for various construction and building projects.

Benefits of Tombstone Engraving CNC Machining

Precision and Accuracy

The CNC technology employed in these machines allows for exceptional precision. Operators can achieve detailed engravings and cuts that manual methods simply cannot match.

Increased Efficiency

With features like high-speed spindles and efficient cooling systems, the CNC Tombstone Stone Engraving Machine operates at high speeds while maintaining quality. This efficiency leads to faster turnaround times for projects.

Flexibility in Design

The ability to create intricate designs digitally means that modifications can be made quickly and easily. This flexibility is a significant advantage for custom projects where client specifications may change.

Reduced Labor Costs

By automating many of the processes involved in stone carving and engraving, businesses can reduce labor costs. The machine’s efficiency means fewer workers are needed, allowing companies to allocate resources more effectively.

How to Choose the Right Tombstones For CNC Machining

When selecting a CNC stone engraving machine, consider the following factors:

- Material Compatibility: Ensure the machine can handle the specific types of stone and materials you plan to work with.

- Machine Specifications: Look for features like spindle speed, cooling systems, and software capabilities.

- User-Friendliness: Choose a machine with intuitive software that matches your team’s skill level.

- After-Sale Support: Opt for a manufacturer that offers comprehensive support and training to ensure smooth operation.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.