Blog

High-Precision CNC Machine for Stone Cutting and Engraving

In the world of stone cutting and engraving, precision is key. High-precision CNC machines for stone cutting and engraving are revolutionizing the industry by providing unmatched accuracy, speed, and versatility.Whether you’re working with granite, marble, or other natural stones, having the right equipment can make all the difference. CNC machine for stone cutting and engraving uses a computer-controlled system to automate the process of cutting, shaping, and engraving stone materials with extraordinary precision. These machines are equipped with advanced tools, allowing operators to create intricate designs and smooth finishes that would be difficult or impossible to achieve by hand. The high precision offered by these machines makes them ideal for various applications, including:

- Monuments and Tombstones: Detailed engravings and carvings for personalized memorials.

- Architectural Stonework: Custom-cut stones for facades, flooring, and decorative elements.

- Interior and Exterior Design: Engraving stone countertops, tiles, and other design elements.

- Sculpture: Creating complex, artistic stone pieces with fine details.

Key Features of High-Precision CNC Stone Cutting Machines

5-Axis Cutting Capabilities

High-end CNC stone machines often feature 5-axis capabilities, allowing for multi-dimensional cutting and engraving. This means they can work from almost any angle, providing exceptional freedom for detailed and intricate designs. It’s especially beneficial for sculptors and artisans looking to create 3D engravings or complex stone carvings.

High-Speed and Efficiency

Traditional stone cutting methods can be time-consuming and labor-intensive. CNC machines significantly reduce production time by automating the process, ensuring consistent results with minimal human intervention. Advanced technology, such as diamond-coated tools and automatic tool changers, contributes to both speed and precision, making these machines perfect for high-volume production.

Precision Control

CNC machines operate through computer programming, which ensures that every cut, carve, and engraving is done to exact specifications. This level of control means that there’s little to no room for error. Whether you’re cutting granite for a countertop or engraving delicate patterns on marble, the result is always consistent, and the quality is top-notch.

Durability and Versatility

These machines are designed to handle a variety of stones, including hard materials like granite and marble, as well as softer materials like limestone. Built with heavy-duty frames and advanced cooling systems, CNC machines are durable enough to withstand long working hours, even when working with tough stones.

User-Friendly Software Integration

Modern CNC machines are integrated with CAD/CAM software, enabling stoneworkers to design intricate patterns and directly translate those designs into machine commands. This software allows for seamless transition from design to production, making it easier for both experienced professionals and beginners to use the machine effectively.

Benefits of High-Precision CNC Machines for Stone Cutting

- Enhanced Accuracy: Achieve flawless cuts and engravings with minimal human error.

- Customization: Create unique, detailed designs that meet client specifications.

- Cost Efficiency: Increase production speed while reducing material waste and labor costs.

- Consistency: Produce uniform results in large batches, ideal for high-volume projects.

Versatility: Work with a wide range of stone materials for various applications, from decorative to functional.

Versatility: Work with a wide range of stone materials for various applications, from decorative to functional.

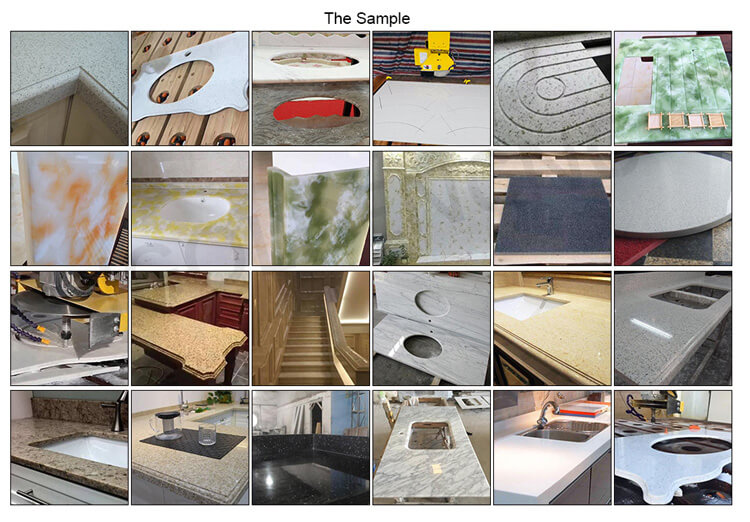

Applications of CNC Machines for Stone Cutting and Engraving

Tombstones and Monuments

CNC machines for tombstone engraving offer the precision necessary to carve intricate designs, text, and graphics on granite and marble. Whether you’re creating a custom memorial plaque or an elaborate tombstone, these machines can handle delicate engraving with exceptional accuracy.

Architectural Stonework

For architects and builders, CNC stone routers are perfect for creating custom-cut stone elements for facades, flooring, countertops, and other architectural features. The ability to precisely cut intricate designs means that architects can push creative boundaries while ensuring that all elements are fabricated to exact dimensions.

Stone Sculpting

Artists and sculptors use CNC machines to create 3D stone sculptures. The machine’s multi-axis cutting ability allows for complex geometric forms and detailed sculptures, making it a go-to tool for modern stone artistry.

Decorative Engraving

CNC stone engraving machines can create beautiful patterns on stone tiles, countertops, and slabs. Whether you’re adding a decorative edge to a countertop or engraving a logo or design, the level of detail achievable is unparalleled.

Why Choose a High-Precision CNC Machine for Stone?

For professionals in the stone industry, investing in a high-precision CNC machine is a game changer. It offers efficiency, cost-effectiveness, and unparalleled precision, all of which are essential for achieving top-quality results in stone cutting and engraving. Whether you are in the business of crafting memorials, designing custom architectural elements, or producing decorative pieces, a CNC machine ensures that you can meet your client’s demands with ease.

FAQ: High-Precision CNC Machines for Stone

1. What tools are used for CNC cutting and engraving stone?

Diamond-tipped tools are ideal for CNC cutting and engraving stone, especially because materials like granite and marble are both hard and abrasive. These tools cut through stone with high precision and durability, which helps prevent tool wear and material damage. By using diamond-tipped tools, operators can achieve cleaner cuts and longer-lasting equipment.

2. Can a CNC machine engrave intricate designs in stone?

Yes, CNC machines are capable of engraving intricate designs and patterns in stone. The precision and accuracy of CNC machining allow for the creation of detailed engravings, such as memorials, monuments, and decorative stonework.

3. What are the challenges of CNC cutting and engraving stone?

Some of the main challenges of CNC cutting and engraving stone include tool wear, heat generation, and dust management. Proper tool selection, cutting parameters, and cooling systems are essential to overcoming these challenges.

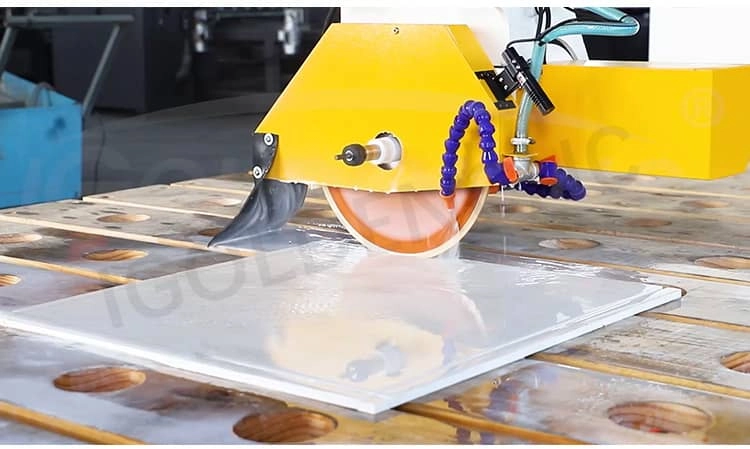

4. Is a water cooling system necessary when cutting and engraving stone?

Yes, a water cooling system is essential when cutting and engraving stone to dissipate heat and reduce friction. Water helps to prevent thermal damage to the stone and flushes away dust and debris from the cutting area.

5. What industries use CNC-machined stone components?

CNC-machined stone components are used in a variety of industries, including construction (for countertops, flooring, and architectural features), memorials and monuments, and decorative stonework. These materials are prized for their durability, beauty, and versatility.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.