Blog

Have you seen stone cnc machines with a variety of functions?

Stone CNC machines have revolutionized the way the stone cutting, engraving, and sculpting industries operate. These advanced machines bring unparalleled precision, speed, and versatility to stone processing, making them indispensable tools in industries like construction, monument making, art, and interior design. But have you ever wondered about the variety of functions these machines can offer? Let’s dive deep into how stone CNC machines with diverse functions can help businesses achieve higher productivity and craftsmanship in stonework.

The Rise of Stone CNC Machines

CNC (Computer Numerical Control) technology has transformed various industries by automating processes that once relied on manual labor. In the stone industry, CNC machines are now essential for a wide range of tasks, from cutting raw stone to creating intricate carvings. What makes these machines stand out is their ability to perform multiple functions with high precision and repeatability, eliminating human error and significantly reducing labor costs.

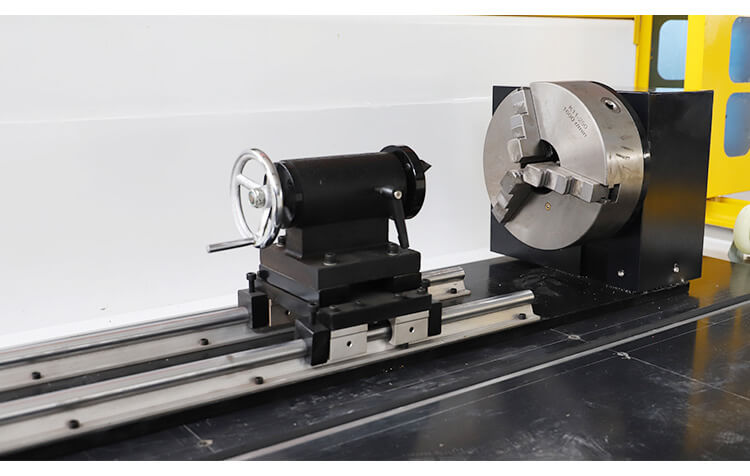

Unlike traditional stone cutting methods, which are limited by manual labor and hand tools, Stone CNC Granite Marble Carving Machines allow for automation and fine control over the stonework process. This opens up a vast range of creative and practical applications, making it ideal for professionals and businesses in various stone-related industries.

Multi-Functionality of Stone CNC Machines

Stone CNC machines are designed to perform a wide range of functions, from cutting and milling to engraving and sculpting. The versatility of these machines makes them a valuable asset for both large-scale manufacturing and small-scale artisan workshops.

1. Precision Cutting

One of the primary functions of stone Computer Numerical Control machines is precision cutting. These machines use diamond-tipped tools and water jets to slice through hard materials like granite, marble, and sandstone with extreme accuracy. The cutting process is controlled by a computer, ensuring that each piece is cut to the exact specifications, whether it’s for countertop fabrication, stone panels, or custom sculptures.

Stone CNC routers can also cut complex shapes, angles, and curves that would be incredibly difficult or impossible to achieve using traditional cutting methods. Whether it’s intricate design patterns or large-scale architectural elements, the precision of CNC cutting ensures that every detail is perfectly executed.

2. Stone Engraving and Carving

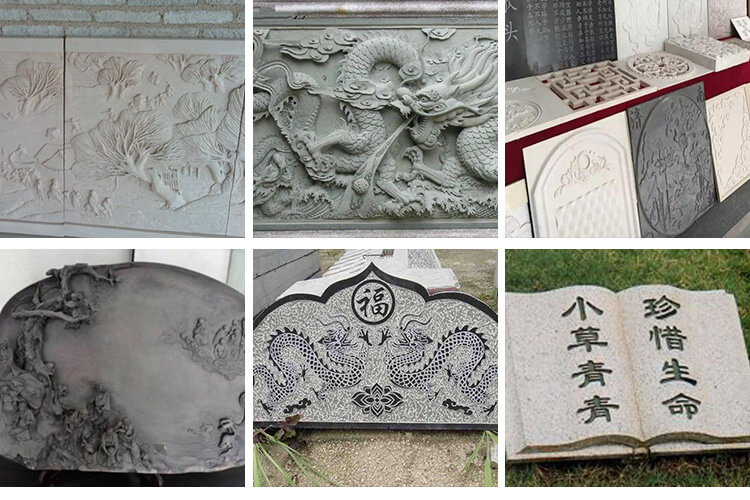

Another remarkable feature of stone CNC machines is their ability to perform intricate engraving and carving. With the right tools, these machines can carve delicate patterns, logos, and text into stone surfaces with impeccable detail. This makes them especially popular for tombstone engraving, custom memorials, and decorative stone elements for homes and businesses.

The carving function on stone CNC machines is controlled with advanced software that allows designers to map out intricate patterns, images, or lettering directly on the machine. The machine follows these digital instructions to carve the stone with precision, leaving behind a beautifully detailed work of art.

3. 3D Stone Sculpting

For stone artists and sculptors, CNC machines have brought the possibility of 3D stone sculpting to life. These machines can carve complex 3D shapes out of solid stone blocks, making them ideal for producing statues, busts, and other detailed sculptures. The versatility of stone CNC machines allows sculptors to explore new forms and abstract designs that would be hard to achieve by hand.

Moreover, 3D stone sculpting through CNC technology can reduce the time and effort required to complete a sculpture, enabling artists to focus more on creativity and less on repetitive tasks. With multiple axes of movement and specialized cutting tools, CNC machines can achieve smoother curves and more precise details than traditional hand carving.

4. Polishing and Finishing

Stone CNC machines are not just limited to cutting and carving—they are also equipped with polishing and finishing capabilities. After the initial cutting or carving process, a CNC machine can apply the perfect finish to the stone surface, ensuring that it meets the desired aesthetic standards. The polishing function removes any rough edges or scratches, giving the stone a smooth, glossy finish.

This function is particularly important for countertops, tiles, and flooring, where a polished surface is crucial for both visual appeal and durability. The high precision of the CNC machine ensures that the polishing is even across the entire surface, maintaining the stone’s natural beauty.

5. Drilling and Boring

Another useful function of stone CNC machines is drilling and boring. These machines can drill precise holes of various sizes into stone, whether it’s for plumbing, electrical installations, or decorative features. Stone CNC machines can also create channels, grooves, and cavities, all of which are common in stone construction, such as in the fabrication of sinks, fireplace surrounds, or stone panels.

The CNC machine’s ability to drill with high precision ensures that the holes and grooves are perfectly aligned and evenly spaced, preventing any imperfections in the final stone product.

6. Custom Fabrication

One of the most exciting features of stone CNC machines is their ability to create custom stone products. Whether it’s a one-off sculpture, a custom countertop, or unique architectural elements, CNC technology allows for the production of highly detailed, tailored products. Designers and businesses can submit digital designs, and the CNC machine will turn them into a physical product with incredible accuracy.

Custom stone fabrication is particularly beneficial for industries like interior design, where bespoke designs and unique aesthetics are in high demand. Additionally, CNC machines can handle both small and large projects, making them adaptable to different business needs.

Benefits of Using Stone CNC Machines

The integration of stone CNC machines into stoneworking processes offers several key benefits that enhance both the efficiency and quality of the work produced.

1. Increased Productivity

Stone CNC machines significantly reduce the time and labor required to complete stone projects. Tasks that would take days or weeks using traditional methods can now be completed in hours. Automation also allows businesses to complete more orders in a shorter period, which is especially beneficial for large-scale production.

2. Precision and Consistency

The ability to work with highly accurate digital designs ensures that each piece is cut or carved with extreme precision. Whether you’re producing a single custom design or a batch of identical pieces, the machine will perform each task with consistency, reducing human error and eliminating imperfections.

3. Cost Efficiency

Although stone CNC machines can be a significant initial investment, they ultimately save money by reducing the need for manual labor, increasing production speed, and decreasing material waste. Additionally, the automation provided by CNC machines means fewer mistakes and fewer costly reworks.

4. Creative Flexibility

Stone CNC machines give designers, sculptors, and manufacturers the ability to execute more complex and creative designs. With the ability to cut, carve, and sculpt with extreme precision, designers have the freedom to bring their creative visions to life, all while maintaining consistent high-quality results.

5. Reduced Labor Costs

Manual stone cutting and carving can be labor-intensive, requiring skilled artisans to perform the work by hand. With CNC machines, businesses can reduce the reliance on highly specialized labor and streamline their operations, making it easier to scale up production.

Conclusion

Stone CNC machines are versatile, powerful, and indispensable tools in the modern stoneworking industry. With a wide array of functions—from precision cutting and engraving to sculpting and polishing—these machines offer the flexibility and accuracy needed to create a diverse range of stone products. Whether you’re producing custom carvings, polished countertops, or 3D sculptures, a CNC stone machine can dramatically improve both the quality and efficiency of your work.

For businesses in the stone industry, investing in a high-quality CNC stone machine can help unlock new possibilities for creativity, precision, and productivity. Whether you’re in the business of construction, monument making, or custom stone art, these machines offer unmatched capabilities for producing top-notch products at competitive speeds.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.