Blog

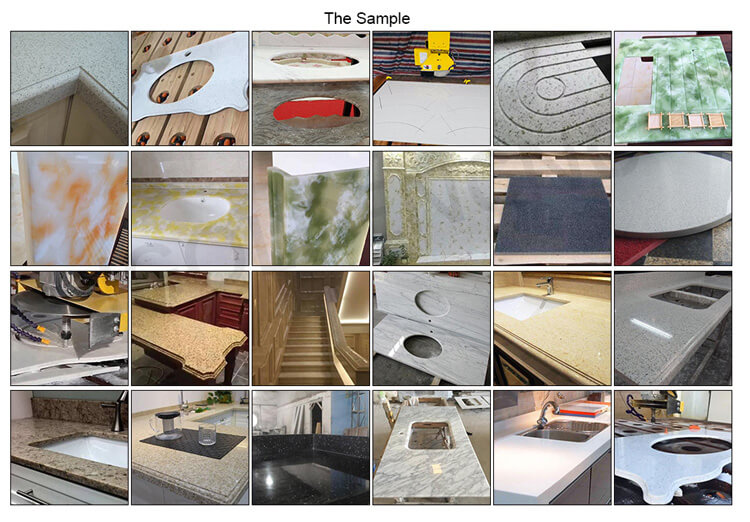

3D CNC Router/Machine Stone Granite Engraving Machine

In the stone engraving industry, the precision and efficiency of a 3D CNC router granite engraving machine are paramount. Whether working with granite, marble, or other types of stone, having the right equipment can significantly enhance the quality of your work. Today, the 3D CNC router has become a revolutionary tool for professionals tackling granite engraving and various stone-related projects.

3D CNC Router Stone Granite Engraving Machine

The CNC (Computer Numerical Control) machine marks a significant advancement in manufacturing. It operates through a computer program that directs the movement of cutting tools, effectively eliminating the variability associated with traditional manual stone cutting methods.

Typically, these machines feature multiple axes—X, Y, and Z—allowing for three-dimensional manipulation of the stone workpiece. The X-axis manages left-to-right movements, the Y-axis controls forward-and-backward movements, and the Z-axis oversees vertical adjustments, enabling intricate shapes and designs.

The term “stone CNC machine” encompasses both stone CNC routers and machining centers, commonly referred to as CNC stone cutting machines, stone carving machines, or marble engraving machines. These machines can carve, cut, drill, and process various materials, including marble, granite, bluestone, and sandstone. For guidance on selecting the best and most affordable stone CNC machine, consult our latest buyer’s guide.

High-Performance Granite Carving Cutting Machine

The granite carving cutting machine is designed for efficient processing and shaping of stone materials, including granite, marble, and quartz. These machines employ advanced technologies to cut, shape, polish, and finish stone products for various applications, such as construction and interior design.

The granite CNC machining center is specifically engineered to create stone kitchen sinks, countertops, and basins. It combines multiple functions, including edging, polishing, drilling, milling, and custom shape cutting. With its intelligent one-button operation, it simplifies tasks like conventional blanking, 45° bevel cutting, and curve cutting.

Stone Processing Center

A granite machining center, often referred to as a CNC router for stone, is a dedicated machine crafted for cutting, shaping, and finishing stone materials. It integrates CNC technology with various tools to streamline the stone processing workflow. These centers are widely used in the stone fabrication industry for cutting slabs, shaping countertops, engraving intricate designs, and polishing surfaces.

3D CNC Granite Machine

The 3D CNC granite machine is a cutting-edge, high-precision stone CNC machining center designed for various types of stone, including sintered stone and ceramic surfaces. It enables complex carving for kitchen tops and table edges. This type of CNC machining center serves as an automated stone cutting tool or a specialized large-scale CNC router, featuring components like granite engraving bits, stone spindles, and advanced processing systems. It efficiently cuts and polishes materials such as quartz, marble, and granite.

3D CNC Granite Cutting Router

The CNC granite cutting machine is a specialized tool primarily used in the stone fabrication sector. This advanced machine is engineered to cut large stone slabs into precise shapes and sizes, making it essential for achieving high-quality finishes. It features a robust bridge structure, a diamond blade, and a motorized system that guides the blade across the stone surface with exceptional accuracy.

The marble CNC machine is a versatile solution tailored for diverse stone applications, catering to both commercial and artistic needs. CNC marble and granite bridge cutters are designed for cutting natural stones, including granite and ceramics. Equipped with a CNC stone saw, these machines excel in special-shaped cutting, polishing, and drilling. They are often referred to as stone bridge saw cutting machines, stone bridge saws for quartz, and tile bridge saws.

4 Axis Marble Bridge Saw

The 4 Axis CNC marble cutting machine is versatile, used for cutting materials such as stone, granite, and ceramic tiles. With four axes of movement, it allows for precise and efficient cutting in multiple directions, enhancing flexibility and versatility for creating intricate shapes and angles.

5 Axis CNC Granite Engraving Machine

The 5 Axis CNC granite engraving machine is an advanced automatic stone machining tool designed to process pentahedron-shaped curved surfaces using five-axis linkage control, which includes three linear moving axes and two rotating axes. Developed by IGOLDENCNC, this innovative machine addresses the unique cutting requirements of the stone machining industry. It offers a range of processing modes, including cutting, milling, engraving, and drilling. The bridge saw is characterized by its multifunctionality, compact design, and ease of operation.

Applications of Granite Engraving Machine Technology in Medicine and Stone Granite Field

Medical Models:In medicine, 3D printing technology enhances the visualization and understanding of the human body. From anatomical models for surgical planning to educational models for medical students, high-precision 3D-printed models play a crucial role. Examples include detailed organ models, skeletal models with accurate joint articulations, and vascular models with intricate branching patterns.

Custom Prosthetics and Orthotics:The demand for personalized medical devices, such as prosthetics and orthotics, has grown significantly. 3D printing enables manufacturers to create devices tailored to each patient’s specifications. Whether it’s a uniquely shaped prosthetic limb or an orthotic brace designed for specific postural issues, 3D printing ensures devices meet individual comfort requirements.

Drug Delivery Systems:3D printing is also advancing novel drug delivery systems, producing dosage forms with complex geometries. Capsules with multiple compartments for sequential drug release and implants with controlled-release mechanisms represent new ways to optimize drug therapy and enhance patient compliance.

Tissue Engineering and Regenerative Medicine:Researchers leverage 3D printing technology to create scaffolds for tissue engineering and regenerative medicine. By fabricating structures with specific architectures and cell-friendly materials, 3D printing enables the engineering of functional tissues and organs in the laboratory, paving the way for revolutionary treatments.

Advantages of Using a 3D CNC Router for Granite Engraving Machine

Using a 3D CNC router for granite engraving provides several advantages over traditional methods. These machines are not only faster and more efficient but also allow for greater precision and consistency in the final product.

1. Precision and Accuracy

CNC routers offer high precision due to computerized controls, allowing fine adjustments to the cutting tool. This ensures every design detail is executed perfectly, especially important when working with hard materials like granite.

2. Increased Efficiency

Traditional stone engraving methods can be labor-intensive and time-consuming. A CNC router can complete tasks in a fraction of the time, leading to higher production rates and enabling larger projects.

3. Versatility

The 3D CNC router can engrave a variety of materials beyond granite, making it a versatile tool for any workshop. Whether working with marble, limestone, or metal, a high-performance CNC router can handle the job.

4. Consistency

The computer-controlled engraving process ensures consistent results every time, which is vital for businesses that need to produce large quantities of engraved products with the same design.

5. Cost-Effectiveness

While the initial investment in a high-performance CNC router may be significant, long-term savings can be substantial. These machines reduce labor costs associated with stone engraving, leading to lower operating expenses over time.

Choosing the Right 3D CNC Router for Granite Engraving Machine

When selecting a 3D CNC router for granite engraving, consider several factors:

Machine Size:Choose a CNC router based on the size of the projects you plan to work on. If engraving large pieces of granite, opt for a machine with a larger work area.

Spindle Power:The spindle is crucial for cutting, so select a machine with a powerful spindle designed for stone engraving.

Precision and Accuracy:Ensure the CNC router offers fine control over the cutting tool, allowing detailed adjustments to the design.

Cooling System:Engraving stone generates significant heat, so choose a router with an effective cooling system, such as a water-cooling system, to prevent overheating.

Software Compatibility:Finally, confirm that the CNC router is compatible with the software you plan to use. Most come with proprietary software, but compatibility with other design programs is essential.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.