Blog

Granite Carving CNC Machine for Professional Stone Engraving

Granite has long been regarded as one of the most durable and aesthetically pleasing materials used in construction, sculpture, and memorial design. Its natural beauty, versatility, and strength make it a preferred choice for a variety of applications, from elegant countertops to timeless memorial stones. In the past, working with granite was a labor-intensive process, requiring significant skill and time. However, with the advent of the granite carving CNC machine, professional stone engraving has become more efficient, precise, and accessible.

Granite carving CNC machine enables users to engrave intricate designs, patterns, and images into granite and other stone materials with a level of accuracy and consistency that was once impossible using traditional hand tools.

What is a Granite Carving CNC Machine?

The granite carving CNC machine is a computer-controlled machine that uses cutting tools such as drills, spindles, and rotary heads to carve, engrave, or mill designs into granite and other stone materials. These machines operate using CNC (Computer Numerical Control) technology, which allows for highly precise movements based on pre-programmed designs. The machine’s operations are controlled by software that converts digital designs into machine-readable instructions, enabling the CNC machine to perform complex cutting and engraving tasks automatically.

Granite carving CNC machines are designed to handle the hardness and toughness of granite, making them ideal for producing professional-grade stone products. They can carve intricate patterns, 3D sculptures, text, logos, and even detailed images into granite surfaces, all with minimal human intervention.

Benefits of Using a CNC Stone Carving

There are several key benefits to using a granite carving CNC machine for professional stone engraving. These advantages contribute to improved efficiency, accuracy, and overall quality in stoneworking.

1. Precision and Accuracy

The most significant advantage of a granite carving CNC machine is its ability to achieve remarkable precision. The CNC system allows for intricate designs to be engraved with high accuracy, eliminating the risk of human error. Whether you’re creating fine text, detailed patterns, or complex 3D sculptures, the machine can reproduce these designs with millimeter-level precision.

Traditional hand carving methods rely on the artisan’s skill and experience, which can lead to inconsistencies, especially in large-scale or mass-production projects. With a granite CNC machine, the machine replicates the same design every time, ensuring uniformity and precision across multiple pieces.

2. Speed and Efficiency

Granite carving using traditional hand tools can be a slow and painstaking process, particularly for detailed or large-scale designs. A granite carving CNC machine, on the other hand, can perform the same tasks much more quickly. The machine can carve at a constant speed, reducing the overall time required to complete a project.

For businesses that need to complete multiple custom stone engravings, a CNC machine offers a significant advantage in terms of productivity. It allows for continuous operation, which increases output without sacrificing quality. This is particularly valuable in commercial applications where timely delivery is essential.

3. Versatility and Customization

4. Reduced Labor Costs

Although the initial investment in a granite carving CNC machine can be significant, the long-term savings can be substantial. Because the machine can work automatically, it reduces the need for manual labor and skilled stone carvers. This leads to lower labor costs and allows businesses to allocate resources to other areas of production. Additionally, the machine’s ability to work continuously can result in faster turnaround times, leading to higher overall efficiency.

5. Consistency and Reproducibility

One of the key challenges with traditional stone engraving is maintaining consistency across multiple pieces. Whether you’re carving several identical memorial stones or producing a batch of custom stone signs, it can be difficult to ensure that each item is exactly the same. With a granite carving CNC machine, consistency is guaranteed.

Once the design is programmed, the machine will replicate it precisely every time, ensuring that all pieces meet the same standards of quality. This is especially beneficial for businesses that need to produce high volumes of engraved stone items in a short period.

Applications of Granite Carving CNC Router

The granite carving CNC machine has found its place in a wide range of industries due to its versatility and precision. Below are some of the most common applications of granite CNC machines in professional stone engraving.

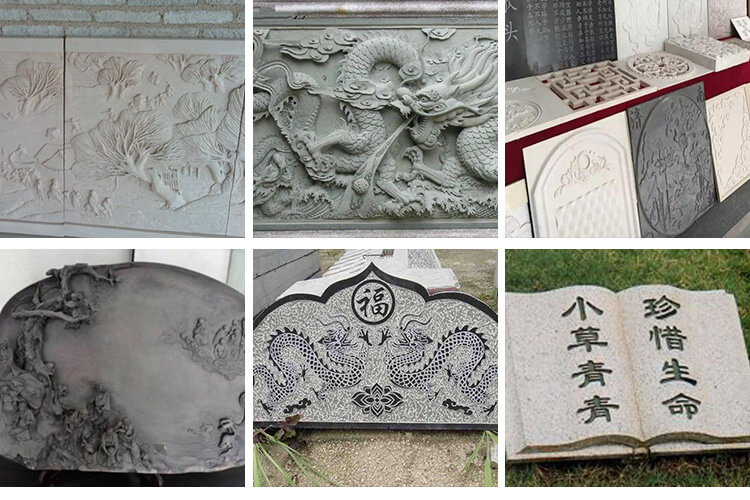

1. Memorials and Gravestones

One of the most popular applications of granite carving CNC machines is the production of memorials, gravestones, and plaques. Stone carvers can use the machine to engrave detailed portraits, text, religious symbols, and decorative elements onto granite headstones with incredible precision.

CNC machines allow for the production of personalized memorials that encapsulate the essence of the departed, making them a perfect option for funeral service businesses. Their capacity to handle diverse stone finishes, like polished and matte, further beautifies the memorials.

2. Custom Signage and Logos

Granite is a popular material for creating custom signage and logos due to its durability and aesthetic appeal. Businesses, universities, parks, and those responsible for monuments use Granite CNC machines to carve company logos, directional signage, and other graphic designs into stone. The machine’s precision ensures that they can perfectly etch logos and text into the granite surface, providing a professional and lasting finish.

Additionally, granite carving CNC machines can be used to create 3D designs and raised lettering, enhancing the overall visual impact of the signage.

3. Architectural Stonework

Granite carving CNC machines are also widely used in architectural stonework. These machines can carve intricate patterns, decorative elements, and structural features into granite for buildings, fountains, and monuments. From columns and pedestals to custom ornamental details, granite CNC machines provide a reliable and efficient way to create complex architectural stone components.

In addition to carving, these machines can be used for shaping and milling granite into the desired size and shape for construction projects.

4. Art and Sculpture

Professional artists and sculptors use granite carving CNC machines to create detailed sculptures and works of art. Whether it’s a portrait bust, an abstract form, or a large-scale sculpture, CNC machines can bring an artist’s vision to life with remarkable detail. The machine allows artists to work with larger pieces of granite and achieve highly detailed results that would be difficult or impossible with traditional carving tools.

Moreover, CNC technology permits the crafting of 3D models, which can be carved from multiple angles to yield lifelike figures and intricate structures.

5. Furniture and Decorative Items

Granite is often used in the creation of high-end furniture pieces and decorative items, such as countertops, tabletops, and vases. Granite carving CNC machines can be used to create intricate patterns and designs on these items, adding a touch of elegance and personalization. Whether you’re creating a custom granite table for a client or designing decorative stone pieces, the precision and versatility of the CNC machine make it an invaluable tool.

Factors to Consider When Choosing a Granite Carving CNC Machine

When selecting a granite carving CNC machine for professional stone engraving, several factors need to be considered to ensure you choose the right machine for your needs.

1. Machine Size and Workspace

The size of the machine and its working area are crucial factors, especially when working with large granite slabs or sculptures. Ensure the machine has a sufficient working area to accommodate your projects, whether they’re large architectural pieces or smaller engraving jobs.

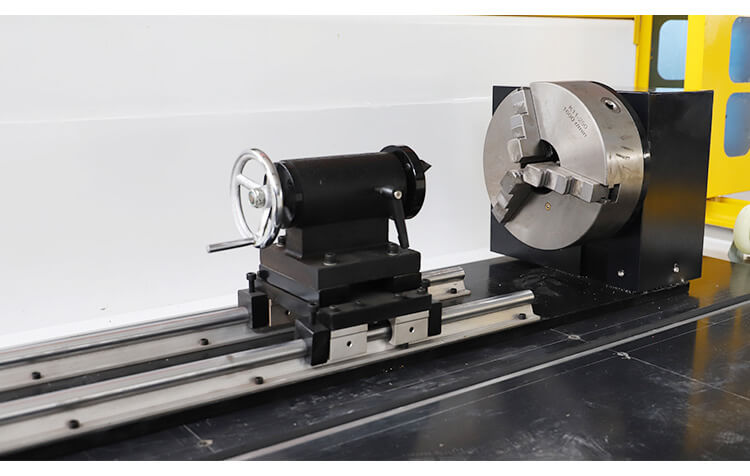

2. Cutting and Engraving Tools

Consider the types of cutting and engraving tools that the CNC machine uses. Some machines are equipped with rotary spindles for detailed engraving, while others use hot wire cutting tools for smoother edges. Make sure the machine is compatible with the types of designs and stone materials you plan to work with.

3. Software Compatibility

A granite carving CNC machine relies on software for design and programming. Ensure that the machine’s software is compatible with common CAD and CAM (Computer-Aided Manufacturing) programs, allowing for seamless design creation and translation to the CNC machine.

4. Speed and Efficiency

Look for a machine that balances cutting speed with precision. The ability to achieve faster processing times without sacrificing quality is important, especially if you’re working on large volumes or tight deadlines.

5. Budget

Granite carving CNC machines can vary widely in price, depending on the features, size, and capabilities. Set a budget based on your business needs, but consider the long-term savings from increased productivity and reduced labor costs.

Conclusion

Granite carving CNC machine is an invaluable tool for professionals in the stone engraving and carving industries. It provides precision, speed and versatility, suiting a wide range of applications from memorials and signage to architectural stonework and sculptures. Investing in a granite CNC machine enables businesses to boost production efficiency, cut labor costs and yield high-quality, consistent results.

Whether you’re a stone carver, architect, or artist,

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.