Blog

Efficient CNC Wooden Kitchen Cabinets Making Machine for Sale

Would you like to invest in a CNC computer cabinet machine for furniture production? Efficient CNC Wooden Kitchen Cabinets Making Machine for Sale. IGOLDEN offers a selection of the most popular furniture CNC machines of 2024, including wood cutting, carving, drilling, grinding, sanding, and laminating machines. We can tailor a complete panel furniture production line to meet the needs of small cabinet shops and large industrial furniture manufacturers. Don’t hesitate any longer – let’s start selecting and purchasing.

Efficient cnc wooden kitchen cabinets making machine

IGOLDEN’s top picks for the most popular furniture CNC machines in 2024, designed for creating semi-custom and custom cabinets. This includes CNC wood cutting machines, carving machines, drilling machines, grinding machines, sanding machines, and laminating machines. We offer customizable complete panel furniture production lines to cater to small cabinet shops as well as large industrial furniture manufacturers. What are you waiting for? Let’s start choosing and buying.

The utilization of CNC technology in the manufacturing of plywood furniture offers numerous benefits. It facilitates efficient production, minimizes material wastage, ensures consistent quality, and enables the creation of intricate and complex designs. CNC routers are capable of producing precise cuts, elaborate patterns, and customized details that would be difficult to achieve manually. Whether it involves crafting chairs, tables, cabinets, shelves or other furniture pieces, CNC technology plays a pivotal role in the production process by empowering furniture makers to efficiently produce high-quality plywood furniture with precision.

This CNC wooden kitchen cabinets making machine is a highly cost-effective CNC router with powerful cutting capabilities. It is capable of milling, drilling, engraving, and cutting work. Its standout feature is the CNC router vacuum table, which automatically absorbs materials using a vacuum pump, eliminating the need for material fixation and thereby improving work efficiency and quality. Alternatively, materials can also be fixed using T-slots if preferred over the auto CNC router vacuum table.

Key Features of CNC Machines for Wooden Kitchen Cabinet Making

When it comes to wooden kitchen cabinet making, not all CNC machines are created equal. High-performance CNC machines designed for woodworking come with specific features that make them ideal for cutting and shaping cabinet components. Some of the key features to look for in a CNC machine for wooden kitchen cabinet making include:

- Powerful Spindles: The spindle is the part of the machine that does the cutting, and it needs to be powerful enough to cut through thick materials like hardwood, MDF, and plywood. Look for machines with high-power spindles designed for woodworking.

- Precision Controls: The ability to make fine adjustments to the cutting tool is crucial for achieving detailed cuts and ensuring that cabinet components fit together perfectly. CNC machines with high precision controls allow for intricate cuts and designs.

- Large Work Area: Depending on the size of the cabinets you plan to produce, you may need a machine with a large work area to accommodate full sheets of material.

- Automatic Tool Changers: Some CNC machines come with automatic tool changers, allowing the machine to switch between different cutting tools without manual intervention. This feature is especially useful for complex cabinet designs that require multiple types of cuts.

- Vacuum Hold-Down System: A vacuum hold-down system helps to secure the material to the machine’s work surface, preventing it from shifting during the cutting process. This ensures that each cut is accurate and consistent.

Benefits of Using a CNC Machine for Wooden Kitchen Cabinet Making

Using a CNC machine for wooden kitchen cabinet making offers numerous advantages over traditional methods. These machines are faster, more efficient, and capable of producing highly detailed and consistent results.

1. Precision and Accuracy

One of the most significant advantages of using a CNC machine for wooden kitchen cabinet making is the level of precision it offers. The computerized controls allow for extremely fine adjustments to be made to the cutting tool, ensuring that every cut is accurate and consistent. This is especially important when producing cabinet components that need to fit together perfectly during assembly.

2. Increased Efficiency

Traditional cabinet-making methods are labor-intensive and time-consuming. A CNC machine, on the other hand, can complete the same tasks in a fraction of the time. This increased efficiency allows for higher production rates, making it possible to take on larger projects or complete more jobs in less time.

3. Consistency

Because the cutting process is controlled by a computer program, a CNC machine can produce consistent results every time. This is especially important for businesses that need to produce large quantities of cabinets with the same design. The machine ensures that each cabinet component is cut to the exact same specifications, reducing the risk of errors and ensuring a perfect fit during assembly.

4. Versatility

A CNC machine is capable of cutting a wide variety of materials, including hardwood, MDF, plywood, and laminates. This makes it a versatile tool for any cabinet-making business. Whether you’re producing custom kitchen cabinets or mass-producing standard designs, a CNC machine can handle the job.

5. Cost-Effectiveness

While the initial investment in a CNC machine may be significant, the long-term savings can be substantial. These machines reduce the amount of labor required for cabinet making, which can lead to lower operating costs over time. Additionally, the increased efficiency and precision offered by CNC machines can help to reduce material waste, further lowering production costs.

Applications of CNC Machines in Wooden Kitchen Cabinet Making

The versatility of CNC machines makes them ideal for a wide range of applications in the kitchen cabinet industry. Some of the most common uses include:

1. Cutting Cabinet Components

One of the primary uses of CNC machines in the kitchen cabinet industry is the cutting of cabinet components. These machines can cut cabinet doors, drawer fronts, shelves, panels, and other components with high precision and consistency. The ability to cut multiple pieces from a single sheet of material helps to reduce waste and maximize efficiency. Additionally, CNC technology allows for intricate designs and customizations, providing flexibility for different styles and specifications, while ensuring uniformity across all pieces.

2. Drilling Holes for Hardware

In addition to cutting cabinet components, we can also use CNC machines to drill holes for cabinet hardware, such as hinges, drawer slides, and handles. We can program the machine to drill holes at precise locations, ensuring that each piece of hardware is installed in the correct position.

3. Creating Decorative Designs

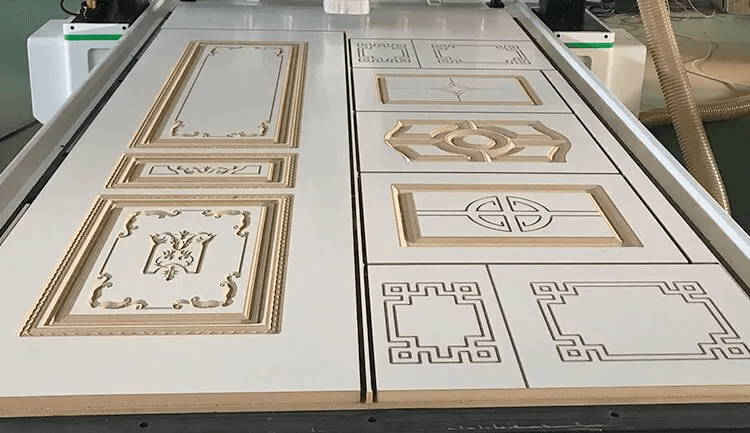

Some CNC machines are capable of creating decorative designs on cabinet doors and drawer fronts. This includes everything from simple grooves and patterns to intricate carvings and raised panel designs. The precision offered by CNC machines allows for the creation of highly detailed designs that would be difficult or impossible to achieve by hand. Furthermore, this capability enables designers to experiment with complex textures, shapes, and finishes, offering a level of customization that enhances the aesthetic appeal of kitchen cabinets while maintaining consistency and quality across multiple units.

4. Edge Profiling

CNC machines can also be used to create edge profiles on cabinet doors and drawer fronts. This includes popular profiles like beveled edges, roundovers, and ogee edges. The machine can be programmed to follow a specific profile, ensuring that each edge is cut to the exact same specifications.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.