Blog

Creative CNC Stone Fabrication for Professional Stone Processing

In the world of stone processing, precision, efficiency, and creativity are the core attributes that differentiate ordinary designs from extraordinary ones. CNC stone fabrication is revolutionizing the stone industry, offering unparalleled accuracy and versatility for professionals involved in marble, granite, and other stone processing applications. Whether you’re creating intricate designs for monuments, countertops, or sculptures, a high-quality CNC stone fabrication machine can help you achieve results that were previously unimaginable.

What is CNC Stone Fabrication?

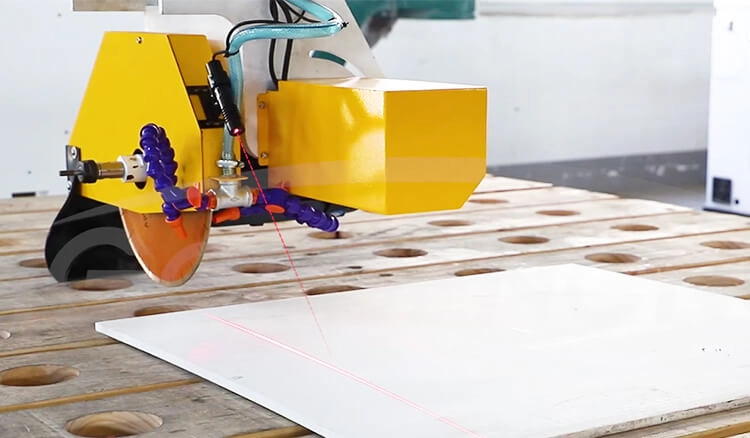

CNC (Computer Numerical Control) stone fabrication refers to the use of computer-controlled machinery to cut, shape, carve, and engrave stone materials with precision. Unlike traditional methods that rely on manual labor, CNC machines use automated programming to execute complex designs with unmatched accuracy. This technology is widely used in industries such as architecture, interior design, construction, and monument making.

By using CNC stone fabrication machines, professionals can save time, reduce errors, and streamline production processes. These machines can work with a variety of stones, including granite, marble, limestone, and other materials, offering flexibility for diverse projects.

Key Benefits of CNC Stone Cutting and Engraving

1. Precision and Accuracy

CNC stone fabrication machines are designed for precision cutting, which ensures that each piece of stone is crafted to exact specifications. With the ability to create intricate patterns, curves, and designs, these machines reduce the risk of human error, delivering perfect results every time. Whether you are carving fine details or cutting large slabs, CNC technology guarantees consistency.

2. Increased Productivity

Manual stone processing can be slow and labor-intensive. CNC machines, on the other hand, operate with speed and efficiency, significantly reducing production time. The automated nature of CNC stone Machining means that tasks that once took hours can now be completed in a fraction of the time. This increased productivity can be a game-changer for businesses, allowing them to take on more projects and deliver faster turnaround times.

3. Complex Design Capability

One of the standout features of CNC stone fabrication is its ability to execute complex designs. Whether you’re working on a highly detailed sculpture or intricate inlays for countertops, CNC machines can handle the complexity with ease. With multi-axis functionality, these machines can make 3D cuts, engravings, and relief designs that would be difficult or impossible to achieve manually.

4. Cost Efficiency

While the initial investment in CNC stone fabrication machines may be higher than manual tools, the long-term savings are significant. These machines reduce material waste, lower labor costs, and minimize errors that could result in costly rework. In addition, the increased efficiency of CNC machines translates to faster project completion, allowing businesses to serve more clients and generate more revenue.

Key Features of CNC Stone Engraving Machines

When considering a CNC stone engraving machine, there are several features to keep in mind to ensure the machine is capable of handling your unique needs:

1. Multi-Axis Capabilities

Most modern CNC stone machines are equipped with multi-axis capabilities, typically ranging from 3 to 5 axes. This allows for complex cutting and carving, such as creating three-dimensional shapes, curves, and detailed designs. The more axes a machine has, the more versatile it becomes in handling intricate tasks.

2. High-Speed Spindles

The spindle is the part of the CNC machine that holds the cutting tool, and its speed directly affects the quality of the cuts. High-speed spindles ensure that stones are cut quickly and efficiently while maintaining a high level of precision. A powerful spindle is essential for cutting through dense materials like granite or marble, which require more force.

3. Dust and Waste Collection Systems

Stone fabrication creates a lot of dust and debris, which can affect both the machine’s performance and the operator’s health. Modern CNC stone processing machines come equipped with dust collection systems that ensure a clean working environment. These systems not only improve air quality but also extend the life of the machine by preventing debris from accumulating in sensitive parts.

4. Advanced Control Software

The software that controls CNC machines is critical to the precision of the cuts. Programs like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) allow operators to create detailed designs and convert them into machine-readable instructions. Look for a machine that supports advanced software, offering flexibility in design and ease of use.

Applications of CNC Stone Processing

CNC stone processing machines are used in a wide range of industries for various applications. Some of the most common uses include:

1. Monument and Memorial Work

CNC machines are ideal for carving intricate designs on memorial stones, tombstones, and monuments. The high level of detail and precision required for such work makes CNC machines an indispensable tool for stone sculptors and memorial craftsmen. With the ability to carve portraits, engravings, and complex patterns, these machines can produce custom designs that honor loved ones with exceptional detail.

2. Architectural Stonework

From columns and facades to decorative stone elements, CNC stone machines are widely used in architectural stonework. These machines can create intricate moldings, relief carvings, and other decorative features that enhance the aesthetic value of buildings. Whether for new construction or restoration projects, CNC machines deliver high-quality results with precision.

3. Countertops and Flooring

CNC stone fabrication is essential in the production of custom stone countertops, backsplashes, and flooring. With CNC technology, stone fabricators can create precise cuts and edges that fit perfectly into kitchen or bathroom layouts. Additionally, CNC machines can engrave unique patterns and designs into countertops, making them stand out as works of art.

4. Sculpture and Art

Stone sculpture is an ancient art form that has been revolutionized by CNC technology. Modern CNC stone machines allow sculptors to produce fine art and sculptures with incredible detail. These machines enable artists to create intricate pieces without the manual labor traditionally required, giving them more time to focus on their designs.

Conclusion

CNC stone fabrication is a game-changing technology for the stone industry. It brings precision, efficiency, and creativity to the table, enabling professionals to craft complex, high-quality stone products quickly and consistently. Whether you’re working on a memorial, architectural feature, or custom countertop, CNC stone fabrication machines can provide the tools you need to elevate your craftsmanship.

Investing in the right CNC stone machine can take your stone fabrication business to the next level, offering enhanced productivity, versatility, and superior quality. As the stone industry continues to evolve, embracing innovative technologies like CNC stone fabrication is crucial for staying competitive and delivering the best results for your clients.

FAQ

1. What materials can be processed with a Engraving machine?

CNC stone fabrication machines can process a variety of stone materials, including granite, marble, limestone, and quartz. Some machines can also work with softer materials like soapstone or sandstone, depending on the capabilities of the machine.

2. How does a machine improve accuracy?

CNC machines use computer-controlled programming to guide the cutting tools, allowing for precise and repeatable cuts. This eliminates the risk of human error and ensures that each piece of stone is cut according to exact specifications.

3. What are the benefits of using multi-axis CNC machines for stone Cutting?

Multi-axis machines allow for more complex cuts and carvings, such as 3D designs and intricate details. This provides greater flexibility and creativity for projects, allowing fabricators to achieve a higher level of detail than with standard 3-axis machines.

4. Is CNC stone fabrication cost-effective?

While the initial cost of a CNC stone fabrication machine may be high, it is a cost-effective solution in the long run. These machines increase productivity, reduce material waste, and lower labor costs, ultimately improving the profitability of stone fabrication businesses.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.