Blog

CNC Stone Tools: Precision Tools for Cutting, Carving & Engraving

In stoneworking, precision is everything. Whether you’re cutting intricate patterns, carving detailed images, or engraving text on materials like granite, marble, or limestone, the tools you use can make or break your results. CNC stone tools offer the perfect solution to achieve high-quality stone craftsmanship. These tools, guided by computer numerical control (CNC) systems, enable professionals to perform delicate operations with incredible accuracy and speed.

In this blog, we’ll explore the various CNC stone tools, their benefits, applications, and how they’ve transformed stone cutting, carving, and engraving.

What is CNC Stone Tool?

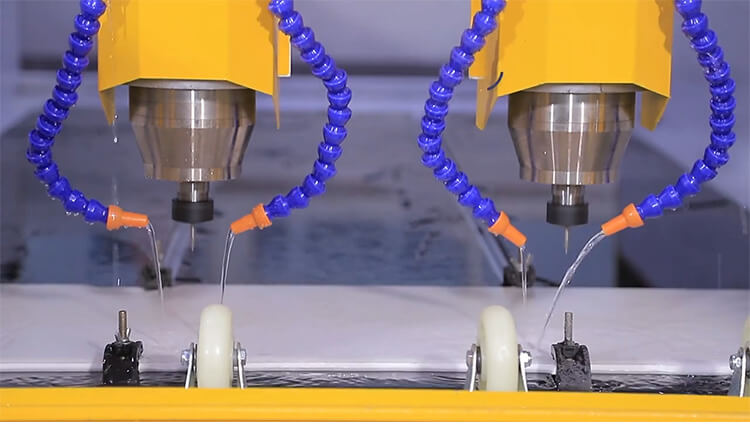

CNC stone tools are specialized tools designed for cutting, shaping, and engraving hard stones such as granite, marble, and limestone. These tools are mounted on CNC machines, which are controlled by computer software to execute precise operations based on digital designs. The tools themselves are made from durable materials like diamond or carbide, ensuring they can withstand the pressure of cutting through tough stone.

With CNC stone tools, artisans can achieve detailed and consistent results that manual methods can’t replicate. These tools are indispensable for industries that require high precision, such as memorial stone carving, architectural stonework, and artistic sculpting.

Types of CNC Stone Tools

Several types of CNC stone tools are available, each serving different purposes depending on the project at hand. Below are the most commonly used tools:

1. Diamond Tools

Diamond tools are a go-to choice for cutting and shaping hard stones like granite and marble. The diamond coating on the tools makes them exceptionally sharp and long-lasting. These tools are ideal for intricate cuts and ensuring smooth, clean edges.

Popular diamond tools include:

- Diamond Blades: Used for cutting through stone with maximum efficiency.

- Diamond Grinding Wheels: Perfect for finishing and smoothing stone surfaces.

- Diamond Router Bits: Excellent for carving detailed designs and patterns.

Diamond tools allow for high-precision cuts, minimizing the risk of chipping and damage, ensuring your projects turn out as expected.

2. Carbide Tools

Carbide tools are more affordable than diamond tools but still offer excellent performance for CNC stone carving. They are especially effective for softer stones like limestone and soapstone. Carbide tools come in various shapes, allowing for fine detailing and engraving.

For softer materials, carbide tools offer a balance between cost-effectiveness and performance, making them popular in many stoneworking applications.

3. Milling Cutters

Milling cutters are designed for more complex carving tasks. These cutters come in a range of shapes, such as flat, ball nose, and corner radius. Milling cutters are commonly used for detailed stonework, from carvings to complex 3D shapes.

These tools are crucial for CNC stone carving, as they can create intricate designs and shapes that other tools might not be able to achieve.

4. Router Bits

Router bits are incredibly versatile tools for carving, engraving, and shaping stone. With a variety of shapes and sizes, they’re great for creating patterns, adding textures, or carving text. Router bits are often used for detail work and for adding depth to stone surfaces.

They’re indispensable for creating customized designs and engraved messages on stone, making them highly sought after for personalized stone products.

Benefits of CNC Stone Tool

1. Unmatched Precision and Accuracy

The key advantage of using CNC stone tool is their precision. CNC machines follow digital designs with extreme accuracy, ensuring every cut, engraving, and carving is consistent and flawless. Whether you’re creating a memorial plaque with precise text or carving a decorative stone with intricate patterns, CNC technology guarantees a level of detail that would be difficult to achieve by hand.

2. Increased Speed and Efficiency

Using CNC stone tools allows for faster production times compared to traditional methods. These machines can complete tasks with minimal human intervention, which speeds up the entire process. This is especially useful for businesses that need to complete high-volume orders.

Additionally, CNC tools help reduce material waste, as the precision of the cuts ensures there’s little to no excess stone removed.

3. Versatility for Various Applications

Another benefit of CNC stone tool is their versatility. These tools can carve, cut, and engrave a wide variety of stones, including granite, marble, limestone, and more. Whether you’re working on large-scale architectural projects or small decorative items, CNC tool provide the flexibility to handle any task.

4. Cost Savings Over Time

Although the initial investment in CNC machines and tools may seem high, the long-term cost savings are significant. CNC tools reduce the need for manual labor, which lowers overhead costs. Furthermore, the precision of the cuts minimizes errors, reducing waste and the cost of reworking faulty pieces.

Applications of CNC Stone Tool

CNC stone tools are widely used in various industries, each requiring precise, customized stonework. Some common applications include:

1. Monuments and Memorials

The monument industry relies heavily on CNC stone tools for engraving memorials, tombstones, and other stone markers. CNC machines ensure that every inscription, image, and design is accurately replicated, providing families with high-quality, lasting tributes. These tools also allow for greater customization, making it easier to create personalized memorials.

2. Architectural Stonework

In architectural stonework, CNC stone tools are used to carve detailed columns, facades, staircases, and other elements. The precision of CNC tools allows architects to create elaborate designs with smooth finishes and clean edges, which are essential for the aesthetic appeal and structural integrity of buildings.

3. Artistic Sculpting

Artists use CNC stone tools to bring their creative visions to life. Whether it’s sculpting a marble statue or carving abstract stone art, these tools offer the precision needed to create complex shapes and designs. CNC technology gives artists the freedom to explore more detailed and innovative works of art, while ensuring that each piece is crafted with perfect symmetry.

4. Custom Stone Furniture and Decorative Items

CNC stone tools are also ideal for creating stone furniture and decorative pieces. From countertops and sinks to tabletops and decorative sculptures, CNC tools allow designers to carve custom patterns, shapes, and textures into the stone. These tools enable the creation of highly personalized and unique pieces that add value to any space.

How to Maintain CNC Stone Machines

Maintaining your CNC stone machines is essential to keep them performing at their best. Here are some tips to ensure their longevity:

- Clean regularly: Stone dust and debris can accumulate, so it’s essential to clean the tool and the CNC machine regularly.

- Sharpen as needed: Tools like diamond blades and router bits may lose their sharpness over time. Regularly check and replace worn-out tools.

- Lubricate moving parts: Ensure the CNC machine is well-lubricated to prevent friction and wear, ensuring smooth operation and extending the machine’s life.

Conclusion

CNC stone tools have transformed the stone industry by offering unparalleled precision, speed, and versatility. Whether you’re working on monument engraving, architectural stonework, artistic sculpting, or custom stone furniture, CNC machines ensure that every detail is captured perfectly. By adopting CNC technology, stoneworkers can achieve higher productivity, meet customer demands for customization, and maintain exceptional quality.

The future of stone cutting, carving, and engraving is bright with CNC stone tool, as these innovations continue to push the boundaries of what’s possible in stone craftsmanship.

FAQ

1. What types of stones can CNC stone tools be used with?

CNC stone tools are designed to handle a variety of stones, including granite, marble, limestone, and soapstone. The tools are adaptable to different material hardness levels, making them suitable for both soft and hard stones.

2. How do CNC stone tools compare to traditional methods?

CNC stone tools offer greater precision, speed, and consistency compared to traditional methods. They also reduce human error, making it easier to replicate designs across multiple pieces.

3. Are CNC stone tools easy to use?

Most CNC stone tools are designed to be user-friendly, with intuitive software that guides the carving and engraving process. Training is typically available for beginners, and most systems offer step-by-step instructions for setup.

4. How can I extend the life of my CNC stone tool?

Regular cleaning, sharpening, and lubrication of your CNC tool is essential for maintaining their performance. Be sure to follow the manufacturer’s guidelines for tool care to maximize their lifespan.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.