Blog

CNC Stone Saw for Custom Stone Cutting and Shaping Solutions

The stone industry has witnessed significant technological advancements, with CNC (Computer Numerical Control) machinery leading the charge. Among these innovations, the CNC stone saw stands out as a game-changing tool for custom stone cutting and shaping. Whether you’re working with marble, granite, limestone, or other natural stones, a CNC stone saw offers unmatched precision, efficiency, and versatility.

What is a CNC Stone Saw?

CNC stone saw is a computer-controlled cutting machine used to shape and cut stone with extreme precision. Unlike traditional stone saws that need manual operation, a CNC stone saw fully automates the process. It can cut intricate shapes, patterns, and designs with minimal human intervention. The machine operates based on pre-programmed instructions, ensuring that each cut is consistent and accurate.

Typically, manufacturers equip these saws with powerful diamond blades that can cut through even the hardest stone materials. People use CNC stone saws for a wide range of applications, from basic cutting and shaping to more complex tasks such as engraving, profiling, and edge finishing.

Key Features of CNC Stone Saws

Advantages and Versatility

One of the major advantages of CNC stone saws is their high precision. The computer-controlled system ensures that each cut is made to exact specifications, which is particularly crucial for custom stone cutting projects. This level of precision minimizes material waste and reduces the need for rework, ultimately saving both time and money. CNC stone saws are also incredibly versatile, capable of cutting a variety of stone types, including granite, marble, sandstone, and more. In addition to straight cuts, these machines can perform angled cuts and intricate designs, such as curves and circles, with ease.

CNC stone saws automate the cutting process, making them much faster and more efficient compared to traditional manual cutting methods. This automation allows operators to process large volumes of stone quickly, improving overall production efficiency. With reduced setup time and faster cutting speeds, CNC stone saws are ideal for projects that require both precision and speed.

Safety and Cost Efficiency

CNC stone saws come equipped with advanced safety features that help protect operators. Since the machines are automated, there is less direct interaction between the operator and the cutting blade, reducing the risk of accidents. Many CNC stone saws are designed with safety sensors, dust collection systems, and emergency stop buttons to ensure a safe working environment.

By reducing manual labor and improving efficiency, CNC technology significantly lowers labor costs. Operators can focus on programming and overseeing operations rather than performing the cutting tasks themselves. This, combined with the machine’s high speed and precision, results in substantial cost savings for stone cutting businesses, allowing them to allocate resources more effectively and boost profitability.

Applications of CNC Stone Saws

Key Applications of CNC Stone Saws

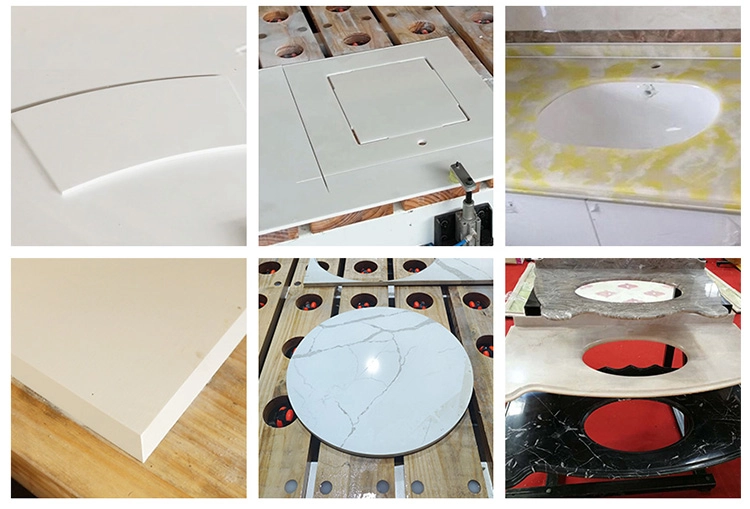

CNC stone saws are essential in various industries that require precise stone cutting and shaping. In stone fabrication, these machines are used to cut and shape stones into countertops, tiles, and vanity tops with exact dimensions. The precision of CNC saws ensures a perfect fit for custom stonework projects, significantly improving both quality and efficiency. The high accuracy of CNC saws ensures that intricate carvings and designs are achieved consistently.

CNC stone saws also play a pivotal role in architectural stone cutting, where they are used to cut stones for building facades, columns, and decorative elements. The machines’ ability to make precise cuts and fit stones perfectly within design specifications is crucial for architectural projects. It has the function of taking photos, positioning and typesetting, automatic measurement of plate thickness and tool size, and the head can rotate 360 degrees. Cutting, edging, chamfering, digging and other multi-functional intelligent operating system, simple and easy to learn; High quality motor, high precision, fast speed; Transverse, longitudinal, arc, circular, arbitrary Angle, shape cutting. The machine head can move and rotate freely. Besides cutting modeling, it can also open material for large plate, 45 degree chamfering, open basin hole, stove hole, and slash line cutting.

CNC Stone Saws in Production and Manufacturing

In addition to custom projects, CNC stone saws are commonly used in stone tile production. The ability to cut large slabs into uniform, precisely sized tiles is essential for the tile industry. CNC machines ensure that each tile is consistent, reducing waste and making installation smoother and more efficient. With their versatility and precision, CNC stone saws continue to be an indispensable tool in industries where stone cutting and shaping are essential for high-quality results.

Why Choose CNC Stone Saws for Custom Stone Cutting?

Key Benefits of CNC Stone Saws for Custom Cutting

CNC stone saws are the preferred choice for custom stone cutting due to their ability to deliver unparalleled customization. These machines enable businesses to meet unique client demands by cutting stone into specific shapes, sizes, and designs. Whether crafting custom countertops, tombstones, or architectural features, the flexibility of CNC technology allows for a wide range of creative possibilities, enhancing both innovation and client satisfaction.

Moreover, reduced material waste is a significant advantage of using CNC stone saws. Precision cutting ensures that every piece of stone is used efficiently, minimizing waste, especially when working with expensive materials like granite or marble. This results in cost savings and improved profitability, as businesses can maximize the potential of each slab.

Long-Term Advantages of CNC Stone Saws

While the upfront cost of investing in a CNC stone saw may be considerable, the cost-effectiveness in the long run is undeniable. The automation and precision of these machines reduce labor costs, decrease material waste, and increase overall productivity. As a result, businesses experience improved profitability and a faster return on investment.

Additionally, enhanced consistency and quality are key benefits offered by CNC stone saws. Unlike manual methods, which can result in inconsistencies, CNC technology ensures that every cut is identical, maintaining high-quality standards across large projects. This is particularly important for commercial applications where uniformity and reliability are essential.

Choosing the Right CNC Stone Cutting Machine for Your Business

When selecting a CNC stone cutting machine for your business, there are several factors to consider. These include:

- Machine Size:The size of the CNC stone saw will depend on the size of the stones you plan to work with. Larger machines can handle bigger slabs, while smaller machines are better suited for intricate designs and smaller stones.

- Cutting Capabilities:Different CNC stone saws offer varying levels of cutting capabilities. Some machines can only make straight cuts, while others can make angled cuts, curves, and even engrave detailed designs. Make sure to choose a machine that meets the specific cutting needs of your business.

- Software Compatibility:Most CNC stone saws are compatible with CAD/CAM software, allowing you to create designs and then translate them directly into machine instructions. Make sure the machine you choose is compatible with the software you’re using or plan to use.

- Ease of Operation:The complexity of the machine’s interface can vary. Look for a machine that is easy to operate, with intuitive controls and clear instructions. A machine that’s easy to learn will help your team get up to speed quickly and improve overall productivity.

- After-Sales Support:When purchasing a CNC stone saw, it’s important to consider the level of after-sales support offered by the manufacturer. This includes training, maintenance, and customer service. A reliable support system ensures that your machine will continue to operate smoothly for years to come.

Conclusion

CNC stone saws have revolutionized the stone cutting industry by offering precision, efficiency, and versatility. CNC stone saw provides the perfect solution for custom stone cutting and shaping. With advanced technology, these machines enable businesses to meet the growing demands of the industry, reduce material waste, and increase profitability.

If you’re looking to enhance your stone cutting capabilities, investing in a CNC stone saw is a step towards achieving superior quality and efficiency. With the right CNC machine, your business can create high-quality stone products that meet the most demanding specifications.

FAQ

Q1: What types of stones can be cut with a CNC stone saw?

A: CNC stone saws can cut a variety of stones, including granite, marble, limestone, sandstone, and other natural stones commonly used in construction and art.

Q2: How does CNC technology improve stone cutting?

A: CNC technology ensures precision and accuracy in every cut, reducing human error and material waste. It allows for intricate designs and custom cuts that are difficult to achieve manually.

Q3: How can I ensure that my CNC stone saw lasts longer?

A: Proper maintenance, including regular cleaning, lubrication, and calibration, is essential to extend the lifespan of your CNC stone saw. Ensure that it is operated correctly and serviced regularly.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.