Blog

CNC Stone Machining Center for Stone Cutting and Engraving

The world of stone carving and engraving has undergone a significant transformation in recent years, thanks to the advent of CNC (Computer Numerical Control) technology. CNC stone machining center has revolutionized the stone industry, offering remarkable precision, efficiency, and versatility in cutting and engraving a variety of stone materials. These machines are now indispensable tools for industries ranging from architectural stonework to monument creation and artistic stone sculpture.

We will also guide you through the decision-making process when selecting the right CNC stone machining center for your needs.

What is a CNC Stone Machining Center?

CNC stone machining center is a high-precision automated tool that cuts, engraves, and shapes stones like marble, granite, limestone, and other natural stones. It features a rotating spindle that holds various cutting tools, such as diamond-tipped bits or carbide tools, to carve intricate designs into stone surfaces. The CNC system controls the machine’s movement along multiple axes using computer programming, ensuring that every cut, carve, or engraving is made with pinpoint accuracy.

CNC stone machining centers are designed to handle complex tasks that require consistent precision. Whether it’s cutting large slabs of marble, engraving detailed designs into granite, or sculpting intricate 3D patterns into stone, these machines can do it all.

Key Features of CNC Stone Router Machine

When choosing a CNC stone router machine, there are several features that set these machines apart from other types of CNC machines. Some of the most important features include:

1. Multi-Axis Functionality

The ability to move along multiple axes is a key feature of CNC stone machining centers. Most stone machining centers have at least three axes (X, Y, and Z), allowing for movement in all three dimensions. However, some machines come with 4, 5, or even more axes, enabling even greater flexibility in creating complex, detailed designs.

- 3-Axis CNC Machines: These machines move in X, Y, and Z directions, which allows for cutting and engraving on flat surfaces.

- 4-Axis CNC Machines: In addition to X, Y, and Z movements, the fourth axis typically rotates the stone or tool to make more intricate cuts, such as curves and angles.

- 5-Axis CNC Machines: These machines provide the highest level of precision, allowing for the cutting of 3D shapes and creating highly detailed, intricate patterns.

2. High Precision and Accuracy

CNC stone machining centers offer exceptional precision, ensuring that every cut, engraving, and shape is executed exactly as planned. The computer control system minimizes human error, allowing stone workers to achieve consistent results across multiple pieces. Whether you’re engraving a small nameplate or sculpting a large monument, CNC technology ensures that each project meets the highest standards of quality.

3. Versatile Tooling Options

A CNC stone machining center can be fitted with a variety of tools to suit different types of stonework. Depending on the project, users can choose from diamond-tipped tools, carbide tools, or other specialized tools for cutting, grinding, and engraving. These versatile tool options make it easy to tackle a wide range of stoneworking tasks, from rough cutting to fine detailing.

4. Automated Programming and Operation

One of the greatest advantages of CNC technology is the ability to automate the process. Operators can create or import designs into the CNC software, which then translates the design into machine movements. Once the program is set up, the machine can work autonomously, saving valuable time and reducing the need for manual labor. This automation ensures that even highly complex designs can be produced with minimal supervision.

5. Robust Build and Stability

Stone machining centers are designed to handle heavy loads, as stones are dense and require substantial force for cutting and shaping. These machines are built with heavy-duty frames and powerful spindles to ensure stability during operation. This robustness is essential for achieving smooth, vibration-free cutting, which is especially important for detailed engraving and fine finishes.

Applications of CNC Stone Centers

CNC stone centers are used across a wide range of industries, with their versatility and precision enabling the creation of various stone products. Here are some common applications:

1. Architectural Stonework

Architectural stonework involves the use of stone in construction projects, such as decorative facades, columns, arches, and flooring. CNC stone machining centers are used to cut and shape stone for these applications with high precision. Designers can create intricate patterns and detailed designs that are difficult or impossible to achieve by hand.

- Stone Tiles: CNC machines can cut and engrave stone tiles for use in flooring or walls, providing consistent sizes and customized designs.

- Stone Panels: For large-scale construction, CNC machines can shape large stone slabs into specific sizes and designs.

2. Monument and Gravestone Creation

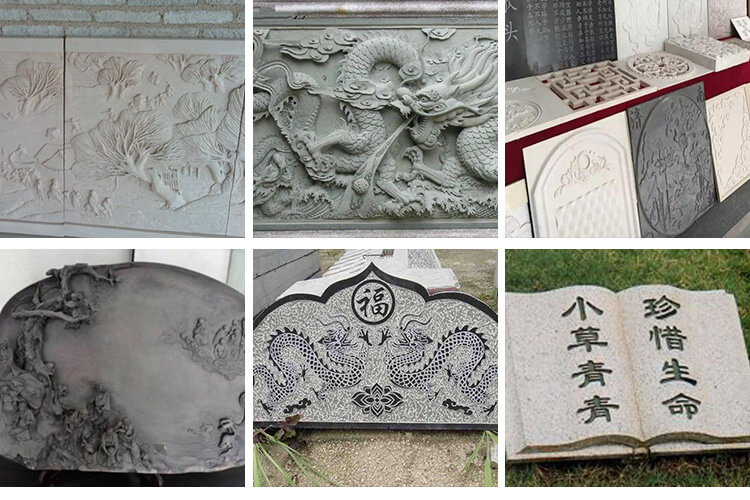

CNC stone machining centers are widely used in the production of monuments, gravestones, and memorials. These machines can engrave personalized messages, names, and intricate patterns on gravestones with great accuracy, making them ideal for the funeral industry.

- Personalized Gravestones: CNC machines enable the engraving of detailed portraits, inscriptions, and designs that honor the memory of loved ones.

- Monument Carving: Large memorial monuments, whether for public spaces or private collections, benefit from the ability of CNC stone machining centers to produce complex carvings and statues.

3. Artistic Stone Sculpture

Artists and sculptors use CNC stone machining centers to bring their creative visions to life. The machines can carve detailed 3D sculptures from large blocks of stone, including everything from abstract art to lifelike portraits. The precision of CNC technology allows artists to create highly detailed, intricate stone sculptures that would be impossible with traditional hand carving techniques.

4. Custom Stone Furniture

CNC stone machining centers are also used in the creation of custom stone furniture. This includes items like stone countertops, tables, sinks, and decorative pieces. These machines enable stoneworkers to cut, engrave, and shape these items to exact specifications, ensuring they fit seamlessly into their intended spaces.

5. Stone Signage

Benefits of Using a CNC Stone Router Center

Using a CNC stone router center offers numerous advantages over traditional stoneworking methods. Here are some of the key benefits:

1. Enhanced Precision and Accuracy

CNC machines are capable of producing intricate, high-precision cuts and engravings with minimal error. This is especially important when working with expensive materials like marble and granite. The ability to repeat complex designs with precision is a huge benefit for businesses that rely on consistency.

2. Increased Productivity

CNC stone machining centers can work autonomously, reducing the need for manual labor and speeding up production times. This leads to increased productivity, allowing businesses to handle more projects in less time and improve overall efficiency.

3. Versatility

CNC machines are highly versatile, capable of handling a wide variety of stone types and applications. Whether it’s for cutting large slabs of granite, engraving fine details on marble, or creating custom stone sculptures, these machines can adapt to different tasks with ease.

4. Reduced Labor Costs

With automation, the need for skilled manual labor is significantly reduced. This allows businesses to lower their labor costs while still maintaining a high level of quality and precision in their stonework.

5. Customization

CNC stone machining centers allow businesses to offer highly customized stone products. Whether it’s a personalized gravestone, custom stone furniture, or an intricate sculpture, CNC machines enable the creation of unique, tailor-made pieces that meet customer specifications.

Choosing the Right CNC Stone Machining Center

When selecting a CNC stone machining center, it’s important to consider several factors:

1. Stone Type and Hardness

Different CNC machines are better suited to different types of stones. For harder stones like granite, a more robust and powerful machine will be necessary, while softer stones may require less intense machinery.

2. Machine Size

The size of the machine should be compatible with the size of the stone pieces you plan to work with. Ensure the machine can handle the dimensions of your material comfortably.

3. Number of Axes

For complex, multi-dimensional work, a 5-axis machine is ideal. However, for simpler, flat cutting tasks, a 3-axis machine may suffice. Consider the complexity of your projects when choosing the number of axes.

4. Budget

CNC stone machining centers vary in price depending on features such as number of axes, size, and technology. Choose a machine that fits within your budget while meeting your production needs.

Conclusion

CNC stone machining centers are essential tools for businesses and craftsmen working in the stone industry. With their unmatched precision, speed, and versatility, these machines have revolutionized the way stone is cut, shaped, and engraved. Whether you’re involved in architectural stonework, monument creation, custom stone furniture, or artistic sculpture, a CNC stone machining center will help you achieve high-quality results with increased efficiency and reduced labor costs.

As CNC technology continues to evolve, the possibilities for stoneworking are endless. Investing in a CNC stone machining center today will ensure that you stay ahead of the competition and produce top-quality stone products for years to come.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.