Blog

CNC Stone Machine for Sale: Unlocking Precision and Versatility in Stone Crafting

In the world of stone carving and engraving, precision and efficiency are paramount. Whether you’re crafting intricate designs for monuments, tombstones, or architectural features, having the right equipment can make all the difference. One such game-changing tool is the CNC stone machine, a versatile machine that is revolutionizing the stone fabrication industry. If you’re considering upgrading your equipment or entering the market, finding the right CNC stone machine for sale can help boost productivity, reduce costs, and improve the overall quality of your work.

What is a CNC Stone Machine?

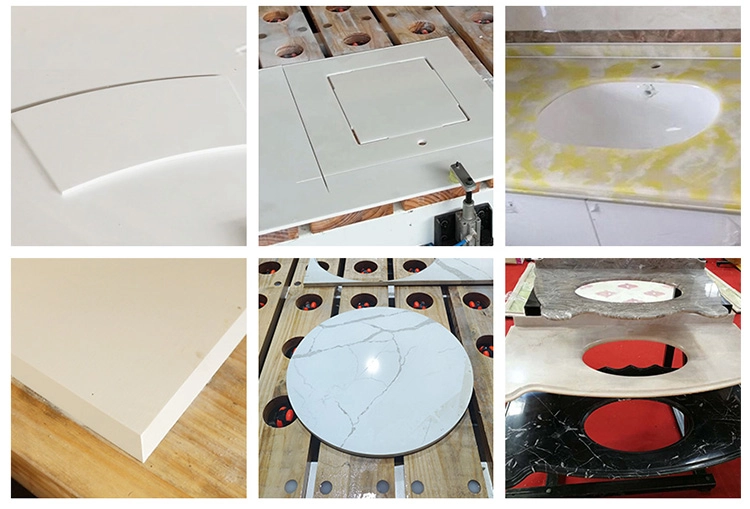

A CNC (Computer Numerical Control) stone machine is a computer-controlled device designed to automate the process of cutting, shaping, and engraving stone materials. These machines use advanced software and high-precision tools to transform raw stone into finely crafted designs. The machine is controlled via a computer interface that sends commands to the machine’s motors, guiding it through the precise steps necessary to complete each cut or engraving.

CNC stone machines are typically used for a variety of stone types such as granite, marble, limestone, and other natural stones. These machines allow for highly detailed, consistent, and repeatable results, making them invaluable in industries like monument making, sculpture, architecture, and interior design.

Why Consider a CNC Stone Machine for Sale?

When it comes to purchasing a CNC stone machine, there are several factors to consider. Not only do you need to think about the machine’s capabilities and specifications, but you also need to weigh factors such as price, after-sales service, and brand reputation. Buying the right machine can significantly enhance your production efficiency and the quality of your stonework.

Here’s why you should consider investing in a CNC stone machine:

1. Precision and Accuracy

One of the main advantages of CNC stone machines is their ability to achieve high precision and accuracy in stone cutting and engraving. With digital controls and automated processes, CNC machines can create intricate designs that would be difficult or impossible to achieve by hand. This level of precision is especially crucial in industries like memorial engraving, where even the smallest details matter.

2. Increased Productivity

CNC stone machines can work continuously and consistently, significantly increasing productivity. Unlike manual methods, which require the operator to work at a slower pace, a CNC machine can complete multiple tasks in a shorter amount of time. This makes it possible to handle larger volumes of work with reduced labor costs and fewer errors.

3. Versatility and Flexibility

Another key benefit of CNC stone machines is their versatility. These machines can handle various types of stone and are equipped with a range of tools and attachments, allowing for a wide array of tasks including cutting, engraving, polishing, and shaping. Whether you’re creating custom gravestones, intricate marble sculptures, or high-end kitchen countertops, a CNC machine can meet your specific needs.

4. Consistency and Reproducibility

CNC machines eliminate the inconsistencies that can occur with manual stone carving. Once a design is programmed into the system, the CNC machine can replicate the same design over and over again with the same precision. This is especially important when you need to create multiple pieces with identical specifications or designs, such as in commercial stone fabrication.

What to Look for in a CNC Stone Cutting

When browsing CNC stone cutting for sale, there are several key features and specifications that can impact the machine’s performance and your decision-making process.

Key Considerations When Choosing a CNC Stone Machine

When selecting a CNC stone machine, several factors must be considered to ensure it meets your project and production needs. The size of the machine and its working area are critical; larger stone slabs require machines with a correspondingly large workspace, while smaller projects can be tackled with more compact machines. Additionally, spindle power and speed are crucial—higher power allows for faster cutting through dense materials like granite, boosting productivity. Precision and resolution are also important for achieving intricate designs, as even slight inaccuracies can be visible in stonework.

Durability, Software Compatibility, and Support

Equally important is the durability and build quality of the CNC machine. Stone cutting and carving are demanding tasks, so opting for machines made of high-quality materials like steel or cast iron ensures longevity and stable performance. Software compatibility is also essential, as most CNC stone machines work with CAD (Computer-Aided Design) software for designing and modifying projects. Be sure to choose a machine that integrates smoothly with the software you plan to use. Lastly, after-sales service and support are crucial; reliable support, including maintenance, troubleshooting, and training, ensures your machine continues to run smoothly and your team can operate it efficiently.

Top CNC Stone Machine Brands to Consider

When looking for CNC stone machines for sale, several well-known brands stand out for their quality and innovation. Below are some top brands to consider:

1. IGOLDENCNC

IGOLDENCNC is one of the leading manufacturers of CNC machines, offering a range of stone machines for both small-scale and large-scale production. Their CNC stone machines are known for their reliability, precision, and ease of use. IGOLDENCNC also offers customization options to tailor the machine to specific project requirements.

2. Biesse

Biesse is a global leader in the design and manufacture of high-tech machinery for wood, glass, and stone. Their CNC machines are renowned for their precision, and Biesse offers a variety of models suited for stone cutting, engraving, and polishing.

3. CMS Industries

CMS Industries specializes in CNC machines for various materials, including stone. They offer top-tier CNC stone machines that deliver superior cutting, engraving, and shaping results. CMS machines are designed for high-speed operations and can handle intricate, complex designs with ease.

4. Sicam

Sicam is another trusted name in the CNC stone machining world. They build their CNC stone routers for precision and efficiency, which makes them ideal for companies involved in monument making, architectural stonework, and other specialized stone projects.

How to Get the Best CNC Stone Machine Price

To ensure you’re getting the best deal on your CNC stone machine for sale, consider the following tips:

- Research Multiple Suppliers: Don’t settle for the first offer you receive. Compare prices, features, and after-sales support from multiple suppliers.

- Check for Discounts and Promotions: Many suppliers offer seasonal discounts, bundle offers, or promotions that can help you get the best deal on your machine.

- Negotiate Terms: Don’t hesitate to negotiate with the supplier, especially if you’re purchasing a larger machine or multiple units. Many suppliers are willing to work with you to reach a price that fits your budget.

- Consider Used or Refurbished Machines: If you’re on a tight budget, consider purchasing a used or refurbished CNC stone machine. These machines are often priced lower but can still provide reliable performance when properly maintained.

Conclusion

Investing in a CNC stone machine for sale can significantly improve the quality, efficiency, and versatility of your stone carving and engraving operations. By understanding the key features and considerations involved in selecting the right machine for your needs, you can make an informed decision that will benefit your business in the long term. Whether you’re working with granite, marble, or other stone types, a high-quality CNC stone machine can take your craft to the next level.

FAQs

1. What types of stone can be used with a CNC stone machine?

CNC stone machines can handle various types of stone, including granite, marble, limestone, sandstone, and more. The machine’s capabilities may vary depending on its specifications.

2. How much does a CNC stone machine cost?

The price of a CNC stone machine varies depending on factors such as size, features, and brand. On average, you can expect to pay anywhere from $20,000 to $100,000 or more.

3. How long does it take to complete a project with a CNC stone machine?

The time required to complete a project depends on the complexity of the design and the size of the stone. However, CNC machines are generally faster and more efficient than manual methods.

4. Can I use my CNC stone machine for engraving and cutting at the same time?

Yes, many CNC stone machines are designed to handle both cutting and engraving tasks, making them versatile for various types of projects.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.