Blog

CNC Stone Engraving Machine for Marble, Granite, and More

In the world of stone fabrication, the need for precision, speed, and versatility has led to the rise of CNC (Computer Numerical Control) machines. These machines have revolutionized how professionals work with hard materials like marble, granite, and other stones. From intricate engravings and carvings to precise cuts, the CNC stone engraving machine has become an indispensable tool for industries that require the perfect combination of craftsmanship and technology.

Overview of CNC Stone Engraving Machine

CNC stone engraving machine is a computer-controlled device designed for the carving, engraving, cutting, and shaping of stone materials. These machines use specialized tools to perform detailed engravings and intricate designs, which are typically too complex or labor-intensive for manual methods. The CNC machine works by interpreting a design file created in CAD (Computer-Aided Design) software and using it to control the machine’s movements with extreme precision.

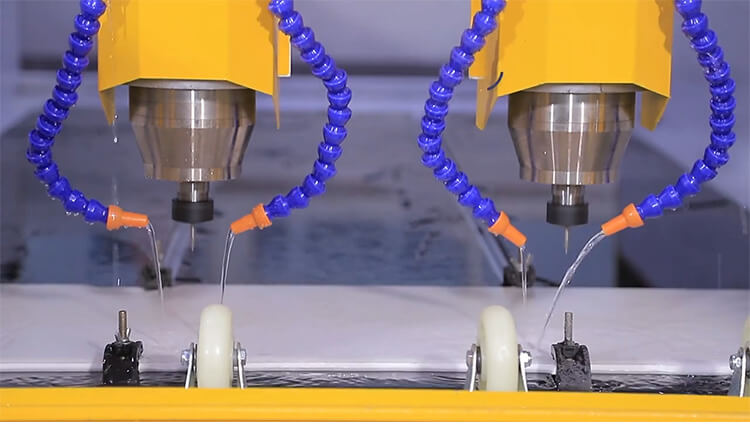

CNC stone engraving machines use spindles or routers that hold various tools, including diamond-tipped bits, to handle the hardness of materials like granite and marble.These machines come in several configurations, including 3-axis, 4-axis, and 5-axis, with higher axis machines providing greater flexibility for complex, multi-dimensional stone work.

Key Features of CNC Stone Engraving Machines

When considering a CNC stone engraving machine, it’s important to understand the features that set these machines apart from traditional methods of stone carving. Here are some of the key features:

1. Precision and Accuracy

CNC stone engraving machines provide unmatched precision, ensuring that every engraving and carving is replicated exactly as per the design. This level of accuracy is especially critical when working with expensive materials like marble and granite, where even a small mistake can be costly.

The use of computer programs and software allows for minute adjustments, so fine details and sharp corners can be carved without human error, resulting in high-quality outcomes every time.

2. Versatility

CNC stone engraving machines are highly versatile. They can cut, carve, engrave, and polish stone, making them suitable for a wide range of applications, from monument engraving to architectural stonework and custom countertops. These machines are equipped with the ability to handle different stone types and designs, offering users the flexibility to take on diverse projects.

For example, a CNC stone engraving machine can switch between tasks like engraving inscriptions on gravestones, cutting intricate patterns for home interiors, or carving detailed artwork for sculptures.

3. Automation and Efficiency

The automated nature of CNC machines dramatically improves efficiency compared to manual labor. With the ability to run continuously with minimal human intervention, CNC stone engraving machines are capable of working on larger batches or intricate designs much faster than traditional stone cutting methods.

Moreover, the time-consuming and physically taxing task of manual engraving is reduced, allowing businesses to save time and costs. Additionally, these machines can work on a 24/7 basis, optimizing production without the need for breaks or downtime.

4. Software Integration

One of the primary advantages of CNC technology is the software integration that allows for quick adjustments and customizations. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software can be used to create designs, modify existing ones, and directly send the data to the CNC machine for execution. This integration not only speeds up the production process but also enables greater creativity and flexibility in designing complex patterns, logos, or custom features for clients.

Benefits of Using CNC Stone Engraving Machines

Investing in a CNC stone engraving machine brings several benefits to businesses in industries such as monument making, interior decoration, and custom stone fabrication. Here are the key advantages:

1. Enhanced Productivity

CNC stone engraving machines allow businesses to significantly increase their productivity. Due to their ability to work on multiple tasks simultaneously and around the clock, these machines can complete jobs faster and with fewer workers. The automation of processes ensures that stone engraving, cutting, and finishing tasks can be done much more efficiently than with manual labor, leading to faster turnaround times for clients.

2. Consistent Quality

Unlike manual stone carving, CNC stone engraving machines deliver consistent quality with every run. The skill and technique of the artisan do not affect the outcome. As long as the design is programmed correctly, the machine will replicate the same cuts and engravings on all pieces. This makes the CNC machine ideal for large-scale production or custom orders that require multiple identical pieces.

3. Cost-Effectiveness

While the initial cost of a CNC stone engraving machine might be higher than traditional hand tools or manual machines, the long-term savings can be substantial. The speed and precision of CNC machines lead to lower material waste, reduced labor costs, and higher output, ultimately resulting in cost savings for businesses. Additionally, the ability to automate much of the work allows for smaller crews and fewer overhead expenses.

4. Ability to Take on Complex Projects

CNC stone engraving machines excel at complex projects that would be difficult, time-consuming, or impossible to execute with manual methods. Whether it’s intricate stone carvings, detailed logos, or custom architectural elements, these machines make it possible to produce highly complex designs with ease. With their multi-axis capabilities, 4-axis and 5-axis machines can also create three-dimensional objects and sculptures, giving businesses the ability to expand their service offerings.

5. Customization and Personalization

Customization is a key trend in many industries, from gravestones to home décor. CNC stone engraving machines allow businesses to offer personalized products, whether it’s engraving a unique message on a memorial stone, creating customized patterns for countertops, or producing artistic sculptures tailored to a client’s specifications. The ability to handle complex custom designs gives companies a competitive edge in providing unique, one-of-a-kind pieces for their customers.

Applications of CNC Stone Engraving Machines

CNC stone engraving machines are used in a variety of industries where stonework is essential. Here are some of the common applications:

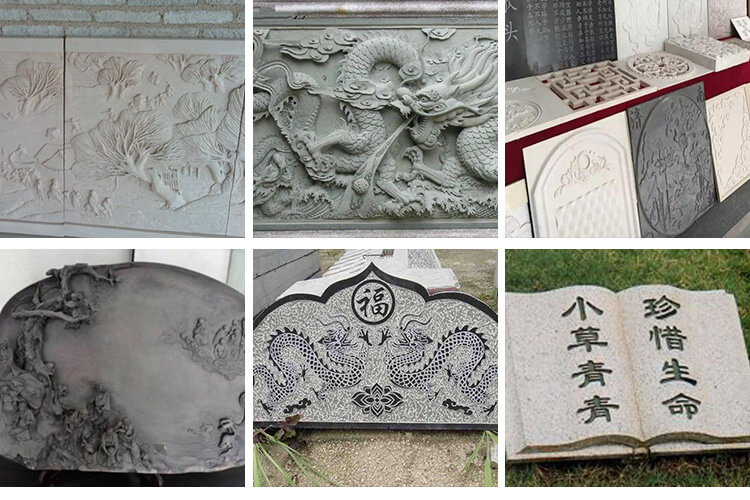

Monument and Gravestone Engraving

CNC stone engraving machines are widely used in the memorialization industry to create custom gravestones, memorial plaques, and monuments. These machines provide highly detailed engraving, allowing clients to include unique inscriptions, portraits, and intricate designs on their gravestones. The precision of CNC machines ensures that these important and permanent pieces meet the client’s expectations.

Interior and Exterior Decoration

CNC stone engraving is also popular in the creation of custom interior and exterior décor elements. From stone panels and sculptures to elaborate fireplace surrounds and kitchen backsplashes, these machines can carve or engrave detailed designs for use in architectural applications. They can also create unique decorative features like custom columns, moldings, and fountains.

Countertop Manufacturing

For kitchen and bathroom countertop manufacturers, CNC stone engraving machines are essential for precision cutting and engraving. These machines ensure that countertops are cut to the correct dimensions and edges are smoothed and polished to perfection. Additionally, engraving designs can be added to the surface for decorative purposes or functional customization, such as personalized logos or artistic patterns.

Artistic Sculpting

Artists working with stone can benefit from the advanced capabilities of CNC stone engraving machines. These machines can carve highly detailed 3D sculptures and artistic designs with intricate details that are otherwise challenging to achieve using traditional methods. From abstract art to lifelike stone portraits, the flexibility of CNC technology makes it easier for artists to push creative boundaries.

Conclusion

In summary, a CNC stone engraving machine is a versatile and powerful tool for anyone working with stone materials like marble, granite, and other hard stones. Whether you are engaged in monument making, custom stonework, architectural design, or artistic sculpting, CNC technology offers the precision, efficiency, and flexibility needed for modern stone fabrication.

By investing in a CNC stone engraving machine, businesses can improve both productivity and quality. They can also offer highly customizable and intricate designs to their clients. This technology enables businesses to take on larger, more complex projects with greater ease. Ultimately, it helps improve profitability and competitiveness. If you’re looking to elevate your stonework business, a CNC stone engraving machine is an investment that can lead to impressive returns and expanded capabilities.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.