Blog

CNC Stone Cutting Machine for Sale

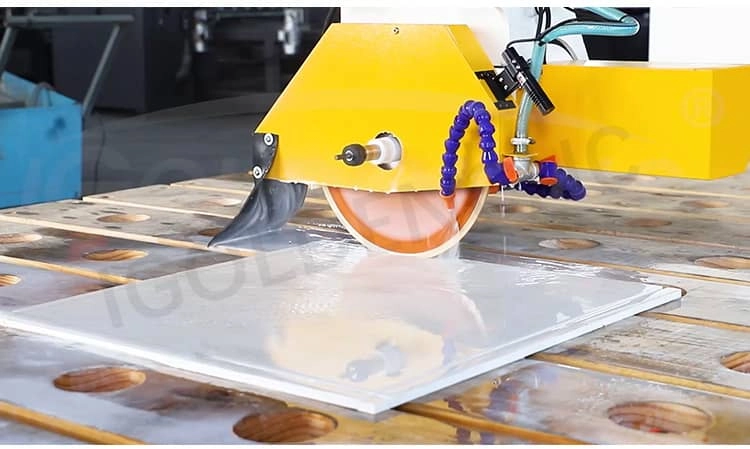

In the world of stone cutting, precision, speed, and efficiency are crucial. Whether you are working on marble, granite, quartz, or any other type of stone, having the right equipment can make a significant difference in the quality of your work. One of the most advanced solutions for stone cutting today is the CNC Stone Cutting Machine.2024 best stone cutting machine in IGOLDENCNC is the best choice for the owner in the business of stone machining, decoration, and sign making. Now the best CNC stone cutting machine for sale at affordable price.This powerful and precise tool is transforming how businesses in the stone industry approach cutting, shaping, and engraving.

This powerful and precise tool is transforming how businesses in the stone industry approach cutting, and shaping.

What is a CNC Stone Cutting Machine?

CNC stone cutting machine is a computer-controlled machine that uses pre-programmed software to cut stone materials with extreme precision. CNC stands for Computer Numerical Control, which means that the machine’s movements are controlled by a computer program instead of manual operations. This allows for highly accurate cuts, intricate designs, and the ability to automate repetitive tasks.

These machines are equipped with powerful diamond-tipped tools that can cut through tough materials such as granite, marble, quartz, and other natural and engineered stones. Whether you’re creating intricate designs, or counter tops, a CNC stone cutting machine can handle the task with minimal effort and high precision.

Key Features of CNC Stone Cutting Machines

Key Benefits of CNC Stone Cutting Machines

High Precision and Accuracy are among the most significant advantages of CNC stone cutting machines. Unlike traditional methods, which are labor-intensive and prone to errors, CNC machines offer consistent and precise cuts. This is particularly valuable for projects requiring intricate designs, where maintaining accuracy is critical.

Versatility is another major benefit. CNC stone cutting machines can handle a variety of stone types, from granite and marble to limestone and engineered stones like quartz and artificial stone. This flexibility makes them ideal for businesses that work with different materials, allowing for diverse applications without the need for multiple machines.

Enhancing Efficiency and Customization

CNC stone cutting machines are highly automated, reducing the need for manual labor and minimizing human error. Once a design is programmed into the system, the machine can perform the task autonomously, boosting production speed and ensuring consistent quality, which is essential for high-volume projects.

Furthermore, CNC technology offers advanced cutting techniques, using tools like water jets and diamond blades for precise and clean cuts in even the toughest materials. Some models also come with engraving tools, enabling businesses to create detailed patterns, text, and artwork on stone surfaces. This advanced capability allows CNC machines to excel in both cutting and engraving tasks.

Finally, CNC machines provide customization and flexibility. With CNC software, businesses can easily create custom designs, whether for unique countertops, intricate stone artwork, or personalized engravings. The ability to modify designs in real-time and create complex shapes with ease sets CNC stone cutting machines apart from traditional methods, offering endless possibilities for stone fabrication.

Benefits of Using a CNC Stone Cutting Machine

Increased Productivity

A CNC stone cutting machine can drastically improve productivity. The automation allows operators to set up the machine, load the material, and then leave the machine to run the job. This means less manual work, less time spent on cutting, and the ability to handle multiple jobs at once. The machine can operate for hours without interruption, significantly increasing output.

Enhanced Precision

When working with stone, the precision of your cuts is paramount. A CNC stone cutting machine eliminates the potential for human error, providing cuts that are accurate to fractions of a millimeter. This is especially crucial in industries where precise measurements are necessary, such as in the production of kitchen countertops, tiles, and memorial stones.

Cost-Effective

While the initial investment in a CNC stone cutting machine can be substantial, it pays off over time. The precision and efficiency of these machines reduce material waste, minimize errors, and lower labor costs. Over time, the increased production capacity and consistency will make your business more profitable.

Greater Design Flexibility

CNC stone cutting machines offer unmatched flexibility in terms of design. If you need to change a design or adjust measurements, the software makes it easy to modify the program and quickly implement the changes. This adaptability is crucial for businesses that offer customized stone products and designs to their customers.

Reduced Waste

With traditional stone cutting, it’s easy to make mistakes that lead to wasted material. A CNC stone cutting machine, however, works with pinpoint accuracy, reducing the chances of cutting mistakes. Additionally, the precise nature of CNC cutting allows for more efficient use of the stone material, minimizing waste and maximizing your material usage.

Applications of 5 Axis CNC Stone Cutting Machines

CNC stone cutting machines are used in a variety of industries for both practical and decorative purposes. Some of the most common applications include:

Intelligent five-axis CNC stone cutting is a full-featured five-axis processing equipment. lt has a camera function for positioning and layout, automatic measurement of sheet thickness and tool size, and the machine head can rotate 360 degrees. Cutting, edging, chamfering, digging and other multi-function integrated intelligent operating system is easy to learn, high-quality motor,high precision and fast speed. Horizontal, vertical, arc, circular, any angle and shape cutting head can be freely moved and rotated. In addition to cutting shapes, it can also cut materials for large plates, 45-degree chamfering,opening pot holes, stove holes, and diagonal line cutting. lt is suitable for stone processing machinery required for quartz stone, slate, artificial stone,granite, marble and various large, medium and small stone decoration projects.Save board, save time, worry and effort!

How to Choose the Best CNC Stone Cutting Machine for Sale

When looking for a CNC stone cutting machine for sale, there are several factors to consider to ensure that the machine meets your business needs:

Size and Capacity

Consider the size of the stone pieces you plan to work with. CNC stone cutting machines come in different sizes, so it’s important to choose one that can accommodate the dimensions of the stones you typically cut. Additionally, look at the machine’s cutting capacity—ensure that it can handle the material thickness you require.

Type of Cutting Technology

There are various types of cutting technologies used in CNC stone cutting machines, including water jets, diamond blades, and laser cutters. Each technology has its strengths and is suited for specific tasks. For example, water jets are ideal for detailed engraving, while diamond blades are better for cutting thick stone. Choose the cutting technology that best suits the type of work you plan to do.

Software Compatibility

Most CNC stone cutting machines work with CAD (computer-aided design) software for precise programming. Ensure that the machine you choose is compatible with the software you plan to use. Some machines come with their proprietary software, while others support industry-standard CAD programs.

Maintenance and Support

It’s essential to consider the maintenance requirements of the machine. Look for a supplier that offers good after-sales support, including machine servicing, spare parts, and technical assistance. Regular maintenance is crucial to keep the machine running smoothly and prevent downtime.

Price and Return on Investment (ROI)

While it may be tempting to opt for a cheaper model, it’s essential to balance cost with the machine’s capabilities. Choose a CNC stone cutting machine that fits within your budget but also offers the features and performance necessary for your business needs. A more expensive machine may offer better long-term value through improved efficiency and precision.

Conclusion

CNC stone cutting machine is an indispensable tool for anyone working with stone, whether you’re in the construction, memorial, or art industry. The precision, efficiency, and versatility offered by these machines allow businesses to produce high-quality stone products faster and more accurately, with reduced waste and labor costs.When considering purchasing a CNC stone cutting machine, make sure to weigh factors such as machine size, cutting technology, software compatibility, and overall cost to find the perfect solution for your needs.

If you’re looking for the best CNC stone cutting machine for sale, take the time to research different options, read reviews, and consult with industry experts to make an informed decision. Investing in the right CNC stone cutting machine will undoubtedly boost your productivity, reduce errors, and help your business stand out in the competitive stone industry.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.