Blog

CNC Routers for Stone: Precision Cutting and Engraving Machines

CNC routers for stone are integral to the modern stone fabrication industry, enabling precise, efficient, and versatile production. These machines are transforming the ways artisans and businesses craft intricate designs, engrave memorials, and fabricate architectural elements. Here’s an in-depth guide to their features, applications, benefits, and maintenance tips.

Features and Technologies That Define CNC Routers for Stone

1. Robust Design for Heavy-Duty Use

Stone CNC routers are engineered for durability, with frames made from cast iron or steel to ensure stability. These materials reduce vibrations, allowing for accurate cuts even during high-speed operations.

2. Precision Spindles and Diamond-Coated Tools

The spindle is the core of any CNC router, and in stone cutting, high-powered spindles paired with diamond-coated tools can effortlessly shape dense materials such as granite and marble. Spindles with variable RPM adjust to different materials, enabling versatile applications.

3. Advanced Cooling Systems

Stone cutting generates heat, which can damage tools or compromise the finish of a product. Integrated water-cooling systems prevent overheating, prolong tool life, and maintain precision.

4. Multi-Axis Capabilities for Complex Designs

Multi-axis CNC routers enable intricate carvings, 3D designs, and smooth finishes. Machines with 4-axis or 5-axis movement allow fabricators to create complex sculptures or detailed architectural pieces.

5. Seamless Software Integration

Modern CNC router work seamlessly with CAD/CAM software like ArtCAM, Alphacam, or Rhino. This technology allows operators to design intricate patterns digitally and execute them with high precision.

Applications Across Industries

CNC stone routers cater to diverse applications:

- Memorial Art: Producing headstones and engraved memorials with custom inscriptions and designs.

- Architectural Stonework: Creating bespoke columns, wall panels, and decorative facades for homes or commercial buildings.

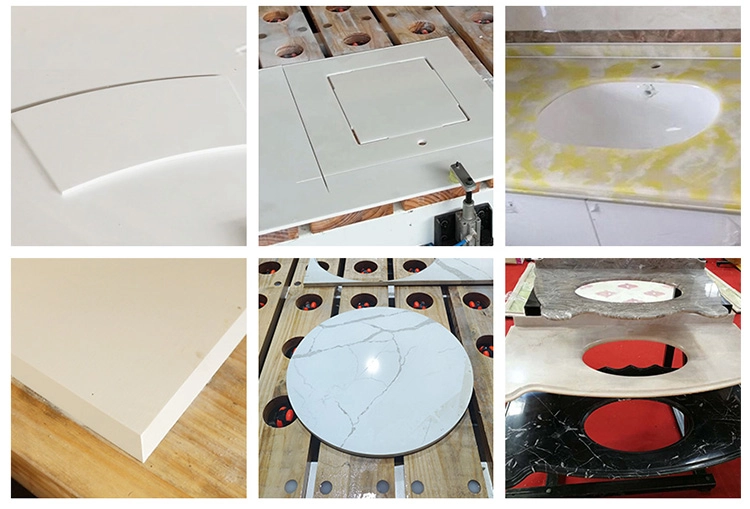

- Countertop Fabrication: Cutting and polishing kitchen countertops, bathroom vanities, and tabletops with flawless precision.

- Industrial Molds: Crafting stone molds and templates for construction or manufacturing purposes.

- Art and Décor: Enabling artists to carve intricate sculptures, bas-reliefs, or decorative ornaments from natural stone.

Advantages of Using CNC Router for Stone

- Precision and Consistency

CNC routers eliminate human error, offering unparalleled accuracy and repeatability for projects of any scale. - Cost Efficiency

Automated systems reduce labor costs and minimize material waste, which lowers production expenses over time. - High Productivity

With faster cutting speeds and multi-axis capabilities, businesses can handle bulk orders without compromising on quality. - Versatility

CNC routers are suitable for various materials, from hard stones like granite to softer options like limestone or engineered quartz. - Enhanced Customization

Advanced software enables users to produce unique designs and tailored engravings, helping businesses meet diverse customer demands.

Choosing the Right CNC Stone Router

To select the best machine for your needs, consider these factors:

- Material Compatibility: Ensure the router can handle the stone types you work with, whether marble, granite, or others.

- Spindle Power: Higher spindle power is essential for dense materials, while lighter projects may require less power.

- Worktable Size: Match the worktable dimensions to the size of your projects. Larger tables are ideal for fabricating big slabs or multiple small pieces simultaneously.

- Software and Ease of Use: Machines compatible with user-friendly design software improve workflow and precision.

- After-Sales Support: A reliable supplier offers maintenance support, spare parts, and training to ensure smooth operation.

Maintenance Tips for Longevity

- Regular Cleaning:Stone dust and debris can clog the machine, so clean it frequently using compressed air and soft brushes.

- Tool Inspection:Check diamond-coated tools for wear and replace them as needed to avoid compromising the cutting quality.

- Lubrication:Lubricate all moving parts to minimize friction and extend their lifespan.

- Software Updates:Keep the machine’s software updated to ensure compatibility with modern design files and features.

- Calibration:Regular calibration ensures the machine maintains cutting accuracy, which is crucial for professional results.

Transform Your Business with CNC Stone Routers

Investing in a CNC stone router is more than a purchase—it’s a strategic move to elevate your craft. From intricate designs to high-volume production, these machines empower businesses to achieve their goals efficiently and consistently.

Take the next step in innovation by exploring our range of CNC stone routers. With advanced features and unmatched reliability, these machines are tailored to meet the demands of modern stone fabrication.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.