Blog

CNC Router Stone Machine: Ideal for Granite, Marble, and More

In the world of stone machining, precision and efficiency are essential. Whether you’re cutting granite, marble, or other dense stone materials, a CNC router stone machine is the perfect tool for achieving intricate designs, clean cuts, and smooth finishes. This blog explores the benefits, applications, and features of CNC router stone machines, offering insights into how these machines can enhance productivity for stone fabrication and design projects.

What is a CNC Router Stone Machine?

A CNC router stone machine is a high-precision, computer-controlled tool designed for cutting and carving hard materials like granite, marble, sandstone, and quartz. With Computer Numerical Control (CNC), these machines can follow intricate designs with remarkable accuracy, making them perfect for complex patterns, detailed engravings, and smooth finishes.

Unlike traditional tools, CNC router stone machines offer unmatched precision, consistency, and efficiency, even on large-scale projects. Whether you’re a small fabricator or a large-scale manufacturer, investing in a CNC router stone machine can greatly improve production capabilities and deliver high-quality results.

Why Use a CNC Stone cutter Machining?

CNC router stone machines bring several advantages to stone machining processes that traditional methods struggle to match. Here are some of the key benefits:

High Precision:CNC router stone machines excel in accuracy, allowing operators to achieve complex patterns, carvings, and engravings that would be difficult or impossible by hand.

Consistency Across Multiple Cuts:When working with large batches of stone materials, consistency is crucial. CNC technology ensures that every piece is identical, reducing errors and waste.

Time and Cost Efficiency: CNC routers automate the production process, reducing manual labor and increasing production speed. This efficiency leads to significant cost savings, especially on high-volume projects.

Versatility in Material Handling: These machines can handle a variety of stone types, from hard granites to delicate marbles and limestones. Adjustable settings allow for precise work with each material.

Safety: CNC routers manage tough materials without direct human intervention, reducing the risk of accidents associated with manual cutting and engraving.

Key Features of a CNC Router Stone Machine

Understanding the features of a CNC router stone machine can help you make the most of its capabilities. Here are the primary elements that make these machines stand out:

Powerful Spindle Motors:The spindle motor drives the cutting tool and determines how effectively it can cut through dense materials. A high-power spindle motor is essential for handling materials like granite and marble without wear and tear.

Four or Five-Axis Capabilities:Many CNC router stone machines operate along four or five axes, which allow for more complex cutting angles and detailed shapes. This multi-axis movement is ideal for sculptural projects, 3D carving, and complex design elements.

Automatic Tool Changers:Some CNC routers include automatic tool changers, which enable the machine to switch between tools without manual assistance. This feature is especially beneficial for jobs that require multiple tools, such as rough cutting, polishing, and fine detailing.

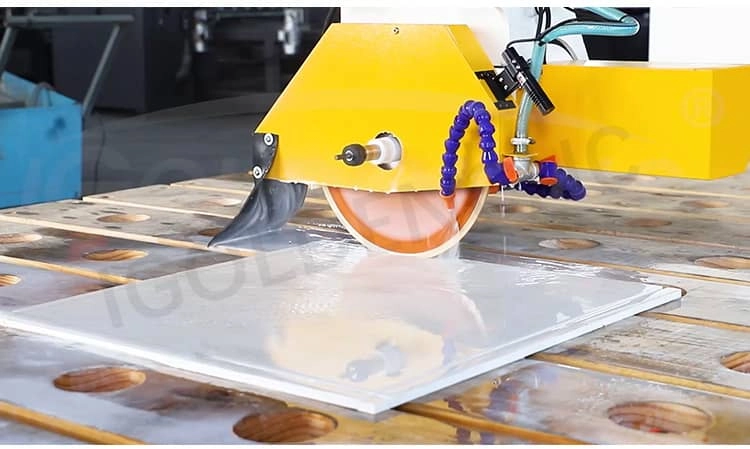

Water-Cooling Systems:Stone machining generates a lot of heat, especially when working with hard stones. Water-cooling systems help dissipate heat, preventing damage to both the stone and the machine itself. These systems also help control dust, improving both safety and visibility during operation.

User-Friendly Software:Advanced but intuitive software allows operators to import CAD/CAM files directly into the CNC router, making it easier to transition from design to production. Many CNC machines come with pre-installed software compatible with various design programs.

Vacuum Table and Clamping Systems:These systems help secure stone slabs firmly during the cutting and carving process, reducing the risk of movement and ensuring cleaner, more precise cuts.

Applications of CNC Router Stone Machines

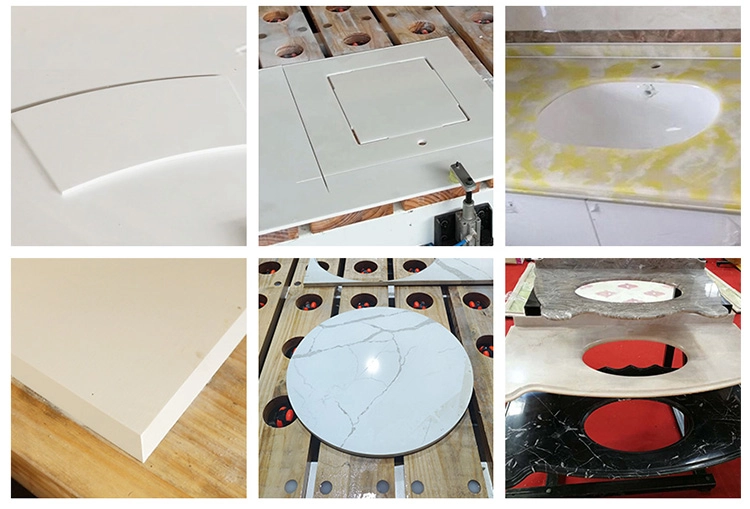

1. Kitchen Countertops and Bathroom Vanities

CNC routers can create beautiful and precise cuts for granite or marble countertops. They enable the creation of smooth edges, integrated sinks, and custom designs that enhance the aesthetic appeal of kitchens and bathrooms.

2. Flooring and Wall Panels

CNC routers are used to produce custom flooring and wall panel designs, including intricate tile patterns, inlays, and borders, adding unique details to interior spaces.

3. Memorial and Monument Engravings

For headstones, memorial plaques, and monuments, CNC routers allow for detailed engravings and etchings. These machines can achieve precise text, patterns, and artwork, providing durable and beautiful tributes.

4. Decorative Stonework

Architects and designers frequently use CNC routers to create decorative stone elements, such as columns, cornices, and moldings, for buildings. These elements add elegance to architectural designs while maintaining structural integrity.

5. Sculptural Art and 3D Carvings

Artists and sculptors use CNC router stone machines for producing sculptures and detailed carvings, achieving complex forms that would take much longer by hand. With the accuracy of CNC technology, every detail is preserved with clarity.

6. Custom Signage

Stone signage for commercial and residential properties is another popular application. CNC routers can carve logos, text, and images into stone, creating attractive and long-lasting signs.

Tips for Getting the Most Out of Your CNC Router Stone Machine

To maximize the efficiency and lifespan of your CNC router stone machine, follow these best practices:

- Regular Maintenance: Perform routine maintenance, including lubrication, cleaning, and inspecting tools, to keep the machine in peak condition.

- Use the Right Tools: Different stones require specific cutting tools. Make sure to select the appropriate tool for each job.

- Optimize Speeds and Feeds: Adjust machine settings based on the stone type. This helps prevent tool wear and ensures smooth cuts.

- Train Operators Properly: Provide training on both the software and machine. This boosts productivity and reduces the risk of errors.

A CNC router stone machine is a game-changer for businesses working with granite, marble, and other stone materials. Its ability to perform precise, intricate cuts with speed and consistency makes it indispensable for industries like countertop fabrication, memorial production, and decorative stonework. With IGOLDENCNC’s advanced and customizable machines, you’ll have the technology and support needed to elevate your stone machining projects.

Whether you’re a craftsman, an architect, or a commercial stone fabricator, investing in a CNC router stone machine can transform the way you work with stone, enhancing quality, efficiency, and creative possibilities.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.