Blog

CNC Router Machine for Marble: Durable, Accurate, and Versatile

In the field of stone fabrication, precision and efficiency are essential for achieving high-quality results. Among the most sought-after tools is the CNC router machine for marble, which offers unparalleled durability, accuracy, and versatility. Whether you’re working on architectural projects, decorative items, or customized designs, these machines are tailored to meet the unique demands of marble processing.

This guide explores the key features, benefits, and applications of CNC router machines for marble, helping you understand why they are indispensable in the industry.

What Is a CNC Router Machine for Marble?

A CNC router machine for marble is a computer-controlled tool specifically designed to cut, carve, engrave, and shape marble. Unlike traditional methods that rely heavily on manual labor, CNC machines bring automation and precision to the process.

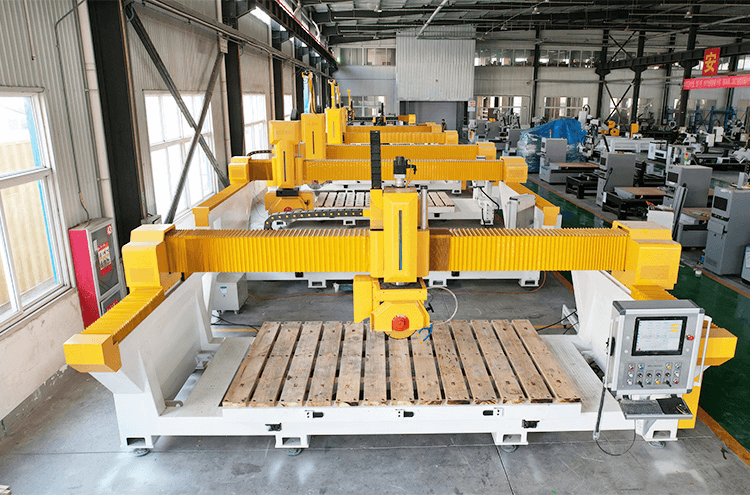

These machines use advanced software to convert digital designs into precise cutting instructions, allowing operators to create intricate and consistent patterns. The combination of diamond cutting tools and powerful spindles ensures smooth operations, even for hard and dense marble surfaces.

Features of CNC Router Machines for Marble

1. Durable Construction

CNC marble routers are built with robust frames, often made from cast iron or steel, to handle the weight and hardness of marble slabs. This durable construction ensures stability and minimizes vibrations during cutting.

2. High-Performance Spindle

Equipped with high-speed spindles, these machines are capable of handling detailed carving and cutting tasks with precision. Spindle power can range from 5.5 kW to over 9 kW, depending on the model.

3. Diamond-Tipped Tools

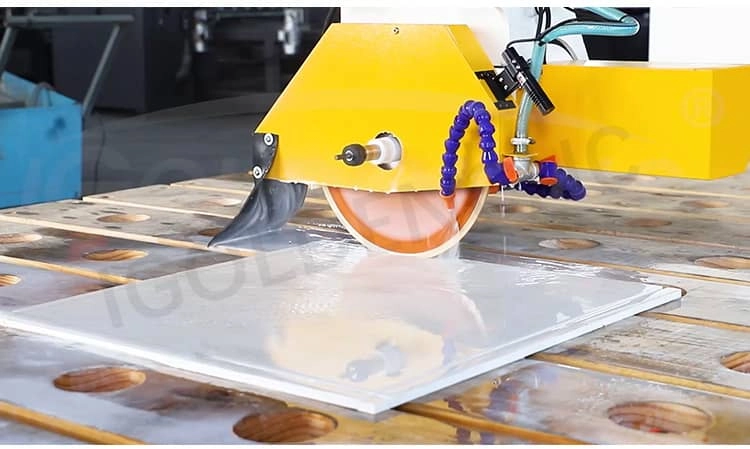

Diamond cutting tools are essential for working with marble, as they can withstand the material’s hardness while delivering clean and accurate cuts.

4. Advanced Software Integration

CNC router machines come with CAD/CAM software compatibility, enabling operators to design, edit, and program complex patterns directly. Some models even feature intuitive touchscreens for easier operation.

5. Water Cooling System

A built-in water cooling system prevents the cutting tools from overheating during continuous operation. This feature also helps reduce dust and prolongs the lifespan of the tools.

6. Large Work Area

CNC router machines for marble typically feature spacious worktables to accommodate large slabs. Adjustable clamps and vacuum suction systems keep the material secure throughout the cutting process.

Benefits of Using a CNC Router Machine for Marble

1. Unmatched Precision

CNC technology ensures high levels of precision, allowing you to achieve intricate designs and flawless finishes that are difficult to replicate manually.

2. Enhanced Efficiency

Automation significantly reduces production time, enabling you to complete multiple projects faster without compromising quality.

3. Versatility in Applications

These machines are capable of performing a wide range of tasks, including engraving, shaping, and edge profiling. This versatility makes them suitable for diverse projects, from countertops to decorative art.

4. Consistent Results

With pre-programmed cutting paths and settings, CNC machines deliver consistent quality across every piece, regardless of complexity.

5. Reduced Material Waste

By optimizing cutting paths, CNC routers minimize waste, ensuring you get the most out of your marble slabs.

Applications of CNC Router Machines for Marble

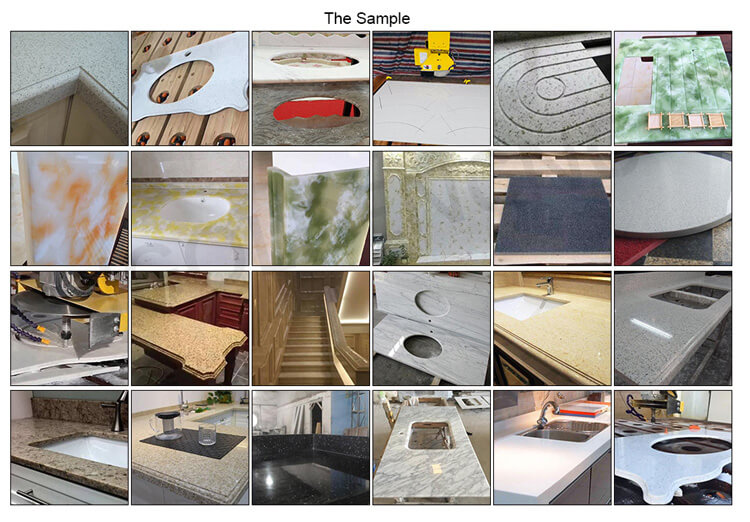

Kitchen Countertops and Backsplashes:CNC routers are widely used to craft custom marble countertops and backsplashes with precise cutouts for sinks and fixtures.

Decorative Wall Panels:Create intricate patterns and textures on marble panels for unique interior and exterior wall designs.

Flooring Inlays:Design stunning marble inlays for luxury flooring, combining precision cuts with artistic flair.

Monuments and Memorials:Engrave inscriptions and intricate designs on marble for monuments, memorials, and tombstones.

Architectural Elements:Craft detailed columns, balustrades, and moldings for architectural projects that require a touch of elegance.

Why Choose IGOLDENCNC’s CNC Router Machines for Marble?

At IGOLDENCNC, we specialize in offering high-quality CNC router machines tailored for marble processing. Our machines combine cutting-edge technology with user-friendly features, making them ideal for both small workshops and large-scale manufacturers.

Advantages of IGOLDENCNC Machines:

-

Wide Range of Models

From entry-level machines to industrial-grade systems, we provide solutions for every need and budget. -

Customizable Options

Our CNC routers can be customized with additional features, such as automatic tool changers (ATC) and rotary attachments, to suit specific applications. -

Exceptional Durability

Built with premium materials, our machines are designed to withstand the demands of marble processing while ensuring long-term reliability. -

Comprehensive Support

We offer installation assistance, operator training, and after-sales service to ensure your machine performs at its best. -

Competitive Pricing

At IGOLDENCNC, we combine quality and affordability, helping you maximize your return on investment.

How to Select the Right CNC Router Machine for Marble

When choosing a CNC router machine, consider the following factors:

- Worktable Size

Select a machine with a worktable that matches the dimensions of your typical marble projects. - Spindle Power

Higher spindle power allows for faster and smoother cutting, especially for thick and dense marble slabs. - Software Compatibility

Ensure the machine is compatible with popular CAD/CAM software for seamless design and operation. - Additional Features

Look for features like automatic tool changers, rotary attachments, and dust collection systems to enhance functionality and ease of use. - Budget and Support

Consider your budget and choose a supplier that offers reliable technical support and warranties.

Conclusion

A CNC router machine for marble is an essential investment for professionals in the stone fabrication industry. With its durability, precision, and versatility, this machine opens up endless possibilities for creating high-quality marble products.

Whether you’re crafting decorative panels, countertops, or architectural elements, a CNC router machine ensures efficiency and consistency in every project. Trust IGOLDENCNC to provide the perfect solution for your marble processing needs.

Contact us today to explore our range of CNC router machines and find the ideal fit for your business!

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.