Blog

CNC Router 5-Axis: Ideal for Intricate Cutting, Engraving&Shaping

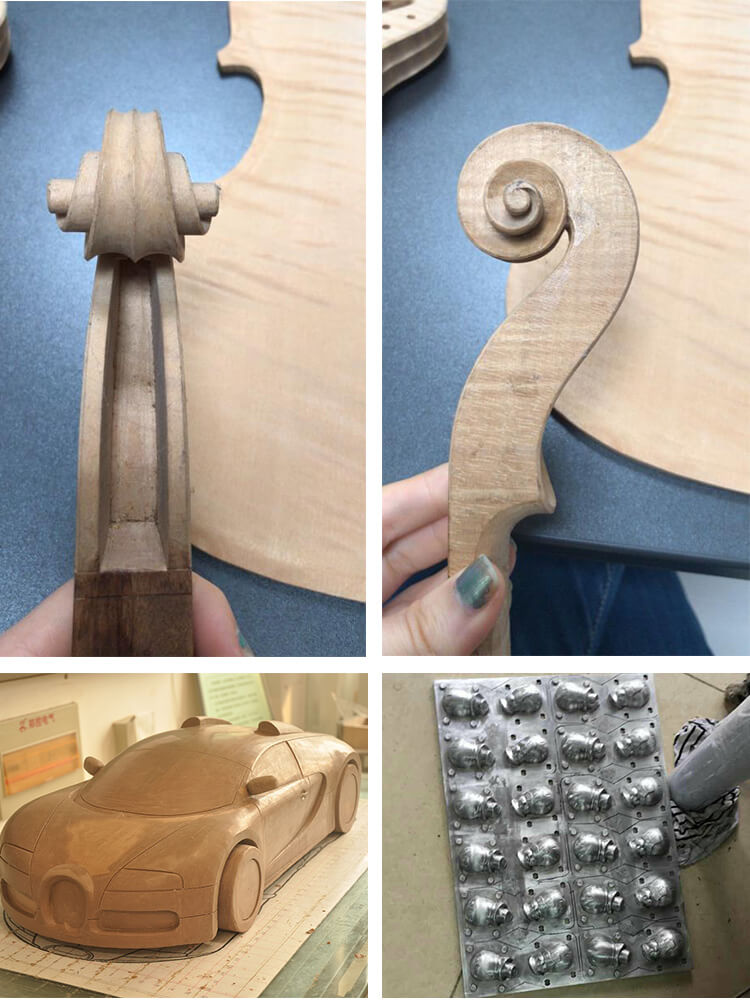

In precision manufacturing, especially when working with materials like wood, metal, stone, and plastic, a CNC router 5-axis machine is a game-changer. These advanced machines offer the flexibility and precision needed for intricate cutting, engraving, and shaping. They open up new opportunities for industries and artisans alike.Whether you’re crafting complex designs or producing high-volume parts with detailed specifications, a 5-axis CNC router ensures unparalleled accuracy and efficiency.

In this blog, we will explore what makes the CNC router 5-axis ideal for complex tasks. We’ll cover its advantages, key features, and applications across various industries. Whether you’re a small business owner or part of a large manufacturing company, understanding these machines’ capabilities will help you make informed decisions about your production needs.

What is a 5-Axis CNC Router?

A 5-axis CNC router is an advanced type of router that operates along five axes to provide precise cutting, shaping, and engraving capabilities. Unlike traditional 3-axis machines, which can move in only three directions (X, Y, and Z), 5 axis CNC routers can move along two additional rotational axes, often referred to as the A and B axes. This additional movement allows the machine to access any part of the material being worked on, even from challenging angles, making it ideal for highly intricate and complex tasks.

This increased freedom of movement enhances the machine’s ability to handle projects that involve cutting, engraving, or shaping detailed patterns, curves, and 3D designs, which would be difficult or impossible to achieve with a 3-axis router.

Key Advantages of Using a 5-Axis CNC Router

1. Enhanced Precision and Detail

The primary advantage of a 5-axis CNC router is its ability to produce highly precise, intricate designs with ease. With five independent axes of movement, the machine can rotate the workpiece to any angle and cut, engrave, or shape it with incredible accuracy. This is especially useful for industries requiring complex geometries and detailed surface finishes, such as aerospace, automotive, and artistic carving.

For example, when engraving a 3D sculpture or cutting a complex mold, a 5-axis machine ensures that every angle is addressed correctly, providing a seamless and detailed result without the need for manual intervention.

2. Increased Productivity and Efficiency

By allowing the tool to approach a workpiece from any direction, the 5-axis CNC router eliminates the need for multiple setups or repositioning of the material. This ability to process the material in a single pass reduces overall production time and the risk of errors. The enhanced efficiency translates into faster turnaround times and lower costs, making it an excellent choice for businesses aiming to improve production capacity while maintaining high-quality standards.

3. Ability to Work with Complex Materials

A 5-axis CNC router excels at handling materials with complex geometries or those that require precision at multiple angles. This includes working with curved surfaces, undercuts, and highly detailed engravings on materials like metals, composites, and stone. The flexibility to tilt and rotate the workpiece opens up new possibilities for industries that work with intricate designs, such as custom jewelry design, mold making, or even medical device manufacturing.

For instance, when creating molds for casting, a 5-axis machine can easily carve intricate shapes and curves in a single operation, reducing the need for retooling or multiple machines.

4. Reduced Human Error

Unlike manual machines that require constant adjustments by operators, a 5-axis CNC router operates on programmed instructions that ensure precision throughout the process. This significantly reduces the chance for human error, resulting in consistent and high-quality output. In addition, many modern CNC routers are equipped with automatic tool changers and sensors to further enhance accuracy and reduce downtime.

5. Versatility in Design and Manufacturing

The 5-axis CNC router is highly versatile, allowing manufacturers to work on a wide range of applications. From detailed engraving on wooden pieces to shaping and milling metal molds, the machine is capable of handling both simple and highly complex tasks. Its flexibility makes it an essential tool for businesses involved in prototyping, custom production, and small-batch manufacturing.

Key Features to Look for in a 5-Axis CNC Router

When shopping for a 5-axis CNC router, there are several key features to consider. These features ensure that the machine will meet your specific production needs and help you get the most out of your investment.

1. High Torque Spindle

For complex cutting and engraving tasks, a high-torque spindle is essential. The spindle’s power directly impacts the machine’s ability to cut through tough materials such as metal, stone, or thick hardwood. A powerful spindle also ensures smoother operation at high speeds, resulting in finer detail and faster cutting times.

2. Advanced CNC Control Software

The software that controls the router is equally important in ensuring smooth operation. Look for a machine with advanced CNC control software that can handle complex tool paths and 3D models. Software compatibility with popular design programs like AutoCAD, SolidWorks, or Fusion 360 is crucial for seamless integration with your design process.

Additionally, modern CNC routers come with user-friendly interfaces that make it easier for operators to input designs, monitor the machine’s status, and troubleshoot any potential issues.

3. Rotary and Tilting Table Options

The ability to rotate and tilt the workpiece is a significant feature of 5-axis CNC routers. A machine equipped with a rotary and tilting table provides greater flexibility for cutting and engraving at various angles, increasing the router’s capabilities and versatility.

4. Durability and Build Quality

Given the heavy-duty nature of 5-axis CNC routers, it is essential to choose a machine with a strong and durable build. Look for machines with high-quality materials such as rigid steel frames and reinforced components to minimize vibrations and ensure precise cutting even at high speeds.

Applications of CNC Router 5-Axis

1. Aerospace and Automotive Industries

In industries like aerospace and automotive manufacturing, precision is critical. 5-axis CNC routers are used to create complex parts with intricate details and tight tolerances. Components such as turbine blades, engine parts, and mold cavities can be manufactured quickly and accurately, meeting the stringent demands of these high-precision sectors.

2. Custom Furniture and Woodworking

For woodworking businesses, a 5-axis CNC router is ideal for crafting intricate, custom furniture pieces with detailed carvings and precise edges. The ability to work with various wood types, such as hardwoods and plywood, as well as create 3D designs, allows for the production of unique, high-quality furniture pieces. The router also excels at creating personalized wood items like engraved panels, signboards, and decorative elements.

3. Medical Device Manufacturing

5-axis CNC routers are increasingly used in the production of medical devices that require high precision, such as surgical tools, implants, and prosthetics. The ability to create detailed and complex designs from materials like titanium, stainless steel, and polymers is invaluable in this sector.

4. Prototyping and Mold Making

For product designers and engineers, 5-axis CNC routers offer an efficient way to prototype and create molds for manufacturing. Whether producing prototypes for new products or molds for casting, the precision and versatility of the machine help reduce development time and costs.

Conclusion

The 5-axis CNC router is a vital tool for any business or artisan aiming to improve their cutting, engraving, and shaping precision. It handles complex, detailed projects and a variety of materials with unmatched flexibility and efficiency.Whether you’re in aerospace, woodworking, medical manufacturing, or mold making, investing in a 5-axis CNC router can improve your production process. It reduces lead times and enhances the quality of your finished products. When incorporating this advanced technology into your workshop, choose a high-quality 5-axis CNC router that meets your specific needs.

FAQs

1. What are the key differences between a 3-axis and a 5-axis CNC router?

The main difference is the number of axes. A 3-axis router can only move in three directions (X, Y, and Z), while a 5-axis CNC router can move in two additional rotational axes (A and B), providing more flexibility for complex shapes and designs.

2. Can a 5-axis CNC router be used for both wood and metal?

Yes! 5-axis CNC routers are capable of handling a wide range of materials, including wood, metals (such as aluminum and steel), plastics, and composites. The machine’s versatility makes it suitable for various industries.

3. How much does a 5-axis CNC router cost?

The cost of a 5-axis CNC router varies depending on the machine’s size, features, and brand. On average, prices can range from $50,000 to $200,000 or more, depending on the specifications.

4. How difficult is it to operate a 5-axis CNC router?

Operating a 5-axis CNC router requires specialized training. However, with modern software and user-friendly interfaces, the learning curve has been significantly reduced, making it easier for operators to use the machine effectively.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.