Blog

CNC for Stone: Precision Cutting and Engraving Solutions

In the world of stone cutting and engraving, precision and efficiency are paramount. Whether you’re working with granite, marble, or other natural stones, having the right CNC (Computer Numerical Control) machine can make a significant difference in your productivity and the quality of your work. In this blog, we’ll explore how CNC machines revolutionize the stone industry by offering unmatched precision, versatility, and efficiency. We’ll also provide a closer look at the key features, benefits, and applications of CNC rock routers and cutting machines.

What is CNC for Stone?

CNC for stone refers to specialized machines designed to automate the cutting, engraving, and shaping of stone materials. These machines use a computer-controlled system to precisely guide the movement of the cutting tool along multiple axes, allowing for intricate designs, smooth cuts, and efficient material removal. Unlike traditional stone cutting methods, CNC machines can handle complex shapes, patterns, and designs with ease, significantly reducing labor costs and material wastage.

Types of CNC for Stone Machines

CNC Stone Routers: These machines are ideal for stone engraving, milling, and detailed carving. They can handle soft stones like limestone, as well as hard stones such as granite and marble.

CNC Bridge Saws: These machines are designed for cutting large stone slabs with precision. CNC bridge saws use a saw blade to cut through various types of stone, including granite, marble, quartz, and engineered stones, offering high-speed and accurate cuts.

5-Axis CNC Machines: These advanced machines can operate on five axes, offering increased versatility and precision for more complex tasks such as stone carving and detailed engraving.

Key Features of CNC Machines for Stone

When considering a CNC for stone, it’s essential to understand the key features that make these machines suitable for stone processing.

High Spindle Power

Stone materials, especially granite and marble, require substantial power to cut through. High-quality CNC machines for stone are equipped with powerful spindles, typically ranging from 6 kW to 15 kW, depending on the machine’s specifications. The greater the spindle power, the more efficiently the machine can cut through harder stones, ensuring precise results.

Multi-Axis Capabilities

Modern CNC stone routers often feature multi-axis capabilities, allowing for more complex cuts and shapes. While traditional CNC machines may operate on 3 or 4 axes, advanced models can work on 5 or even 6 axes. This increased flexibility enables the creation of intricate designs, curved edges, and detailed carvings that would be nearly impossible with manual tools.

Precision and Accuracy

CNC machines are known for their unmatched precision, which is essential in stone cutting and engraving. They can achieve tolerances within fractions of a millimeter, making them ideal for applications that require high levels of detail, such as monument engraving, architectural stonework, and custom countertops.

Automatic Tool Change (ATC)

An automatic tool changer (ATC) system is a valuable feature for CNC machines used in stone processing. It allows the machine to automatically switch between different tools without manual intervention. This feature is especially useful for tasks that require multiple tool types, such as engraving, polishing, and cutting. ATC systems enhance productivity by reducing downtime and increasing the machine’s versatility.

Water-Cooling Systems

Stone cutting generates significant heat, which can cause tool wear and affect the precision of the cuts. Many CNC stone machines feature water-cooling systems that keep the cutting area cool, reducing friction and heat buildup. This results in smoother cuts and extends the life of both the tools and the machine itself.

Benefits of Using CNC Machines for Stone Cutting and Engraving

1. Increased Precision and Quality

The primary benefit of using CNC for stone is the unparalleled precision and quality it offers. CNC machines can replicate designs with high accuracy, making them ideal for intricate work like monument engraving, sculpture, and rock paneling. Whether you’re cutting complex shapes or engraving fine details, CNC technology ensures that your work is consistently accurate.

2. Enhanced Productivity

CNC machines significantly speed up production processes. Tasks that would typically require hours of manual labor can now be completed in a fraction of the time. With features like automatic tool changers and multi-axis capabilities, CNC machines can run continuously with minimal operator intervention, leading to higher productivity.

3. Consistency and Repeatability

Once you program a design into the CNC machine, it can repeat the process as many times as needed, ensuring that each piece matches the previous one. This is especially useful in commercial applications where manufacturers need to produce large quantities of the same design, such as countertops, tiles, and sculptures.

4. Reduced Material Waste

By using CNC machines for stone cutting, you can optimize material usage and reduce waste. These machines are capable of making precise cuts, ensuring that materials are used efficiently and that costly errors are minimized.

5. Versatility

CNC machines for stones are incredibly versatile. They can handle various tasks, including cutting, engraving, polishing, and shaping. Whether working with marble, granite, or other natural stones, a CNC machine can be customized to fit your project’s needs.

Applications of CNC Machines for Stone

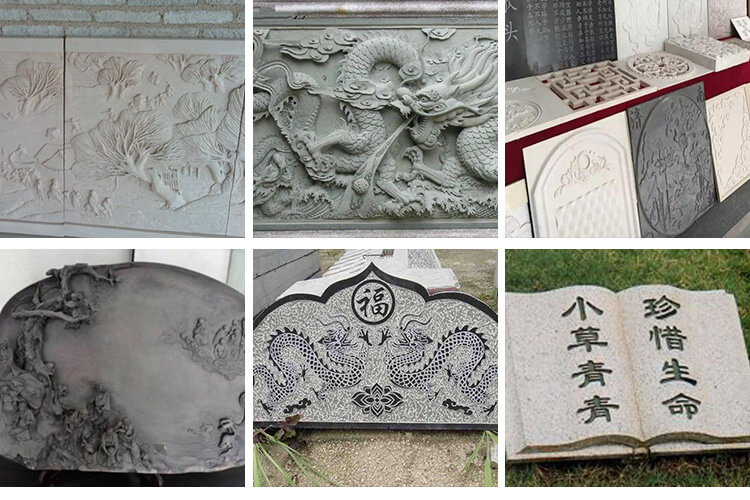

1. Monument and Tombstone Engraving

CNC for stone is widely used in the memorial and tombstone industry. These machines can engrave intricate designs, text, and images on tombstones with high precision. With their ability to handle fine details, CNC machines are perfect for creating personalized memorials.

2. Kitchen and Bathroom Countertops

CNC machines are widely used to fabricate custom countertops. With CNC technology’s precision, you can cut, shape, and polish countertops to meet specific designs and dimensions, ensuring a perfect fit for kitchens and bathrooms.

3. Architectural Stonework

For large-scale construction projects, CNC routers can be used to create architectural stonework, including columns, facades, and flooring. These machines enable intricate designs and detailed carvings that add an artistic touch to buildings and structures.

4. Stone Sculpting

Stone sculptors use CNC machines to create fine art pieces. CNC for rock allows for complex sculptures and carvings to be produced quickly and with remarkable detail. Whether it’s a classical statue or a modern piece of art, CNC machines can bring artistic visions to life with precision.

How to Choose the Best CNC for Stone

When choosing a CNC for stone, there are several factors to consider:

Material Type: Consider the type of stone you’ll be working with (granite, marble, limestone, etc.) and ensure the machine can handle it.

Machine Size: Choose a machine with a sufficient working area for your projects. Larger rock slabs may require a larger CNC router or bridge saw.

Tool Compatibility: Make sure the machine supports the tools needed for your specific tasks (cutting, engraving, polishing, etc.).

Software Integration: Ensure the CNC machine is compatible with your preferred design software to streamline the workflow from design to production.

Support and Service: Look for manufacturers that provide excellent customer support and maintenance services.

CNC machines for stone are revolutionizing the way we cut, shape, and engrave rock. With their precision, speed, and versatility, these machines are ideal for a wide range of applications, from monument engraving to kitchen countertops. By investing in the right CNC for stones, you can improve productivity, reduce material waste, and produce high-quality results with ease.

Whether you’re a stone fabricator, sculptor, or memorial manufacturer, CNC machines are a valuable tool that can help you take your business to the next level. Choose the right machine for your needs, and experience the benefits of precision stone cutting and engraving.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.