Blog

CNC Foam Cutter Machine: Your foam making powerful helper

In the fast-paced world of manufacturing, precision and efficiency are key. Whether you’re in the construction industry, film set design, custom packaging, or creating artistic sculptures, one piece of machinery can drastically improve the quality and speed of your work: the CNC foam cutter machine. This highly versatile tool revolutionizes how foam is cut, shaped, and sculpted, offering an array of applications across various sectors.

What is a CNC Foam Cutter Machine?

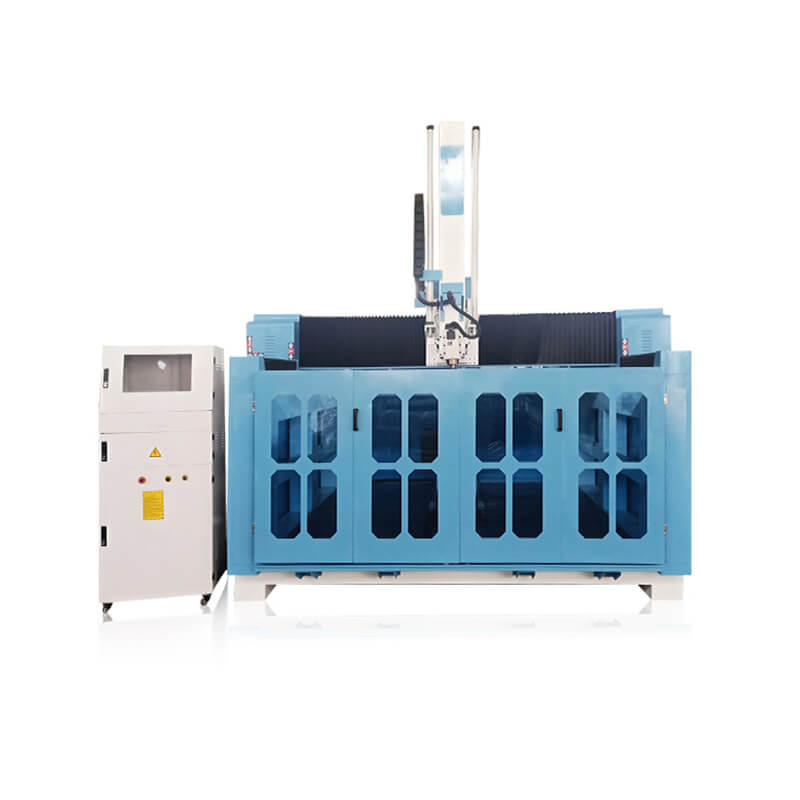

CNC foam cutter machine, which is an automated tool, precisely cuts and shapes foam material. It differs from traditional foam cutting methods as it is computer-controlled. This control enables it to make high-accuracy cuts, create intricate designs, and achieve rapid production times. These machines work by interpreting a digital design file, typically in CAD (Computer-Aided Design) format, and then following the programmed instructions to cut foam into the required shape.

Key Components of a CNC Foam router:

- Cutting Tools: These could include hot wire cutters, blades, or rotary cutters depending on the type of foam being cut and the design.

- Controller Unit: The computer or software system that interprets the digital design and controls the movement of the cutting tool.

- Motion System: This involves the machine’s axes (X, Y, Z) and the movement of the cutting tool to achieve precision cuts.

- Foam Handling: The foam is placed on a flat table, and the machine’s automated arms move it into place for cutting.

Advantages of Using a CNC Foam Cutter Machine

Key Advantages

CNC foam cutter machines stand out for their precision and accuracy, ensuring that every cut aligns perfectly with the design specifications. Whether for simple shapes or intricate patterns, the machine follows the exact coordinates from the design file, offering consistency and reducing material waste. This is especially important in industries like packaging, where custom foam inserts need to fit precisely around fragile products.

In addition to precision, CNC foam cutters offer remarkable efficiency and speed. Once set up, the machine can process large volumes of foam quickly, making it ideal for high-demand production environments. The automation of the process eliminates manual intervention, increases production rates, and significantly reduces labor costs, making it a cost-effective solution for mass production.

Enhanced Capabilities and Safety in Foam Cutting

CNC foam cutter machines also excel in their complex design capabilities, allowing for the creation of detailed sculptures, custom shapes, and intricate prototypes. Unlike manual cutting methods, CNC machines can handle even the most complex designs with ease, enabling manufacturers to achieve high levels of creativity and innovation. This capability is crucial in industries such as advertising, where custom foam signage and displays are needed.

Moreover, CNC foam cutters ensure consistency and repetition, producing identical foam parts with every run. This is essential in manufacturing processes that require large quantities of the same item, such as custom packaging or automotive components. With safety features integrated into the machine, the risk of accidents is minimized, ensuring a safe working environment and reducing human error during operation.

Applications of CNC Foam Cutter Machines

The versatility of CNC foam cutter machines makes them an essential tool in a wide variety of industries. Here are some common applications:

- Custom Packaging Solutions:

One of the most popular uses for CNC foam cutting machines is creating custom foam inserts for packaging. Whether you’re shipping fragile items, electronics, or industrial parts, foam inserts can be cut to perfectly fit the shape of the product. This provides superior protection during transport, reducing the risk of damage. - Film and Theatrical Design:

In the entertainment industry, CNC foam cutters are used to create intricate and large-scale props, scenery, and models. From movie sets to stage designs, CNC machines can cut foam into elaborate shapes for use in both visual effects and physical props. This is particularly useful for creating detailed sculptures, models, and even architectural elements. - Art and Sculpture:

CNC foam cutters are a favorite tool among artists and sculptors who need to carve large-scale foam sculptures or prototypes. The ability to create highly detailed foam sculptures quickly and with precision allows artists to produce more intricate designs with ease. - Architectural Models:

Architects and designers often use CNC foam cutters to create scale models of buildings and landscapes.The CNC foam cutter machine can quickly and accurately cut foam into various shapes, helping to create detailed prototypes for presentations and design evaluations. - Prototyping and Product Development:

In product development, CNC foam cutters are invaluable for creating prototypes. Whether you are developing a new product for testing or designing components for engineering purposes, CNC foam cutters allow you to quickly iterate designs and test prototypes before moving to more expensive production methods.

Factors to Consider When Choosing a CNC Foam Cutter Machine

When selecting a CNC foam cutter machine, there are several key factors to consider to ensure that the machine meets your specific needs:

When selecting a CNC foam cutter, the machine size and work area are crucial considerations. Depending on your needs, choose a machine with a work area that can accommodate the size of foam sheets or blocks you plan to cut. While manufacturers make smaller models suitable for cutting small parts, they design larger machines for cutting bigger foam slabs, which makes them ideal for large-scale projects.

The cutting type is another important factor. CNC foam cutters offer various cutting methods, such as hot wire cutting, rotary cutting, and blade cutting. Manufacturers design each type for different foam densities and applications. For example, hot wire cutters excel with softer foams, while rotary cutters are better adapted for denser materials.

Performance and Longevity of CNC Foam Cutters

Software compatibility plays a significant role in the efficiency of your CNC foam cutter. Ensure the cutter is compatible with the CAD software you use, and can accept common design file formats like DXF or STL. This ensures smooth integration between design and production processes, enabling easy conversion of designs into machine-readable instructions.

In addition to compatibility, speed and efficiency are key to maximizing productivity. Look for a machine that can operate at high speeds without compromising accuracy. Also, consider the machine’s operational cost, as energy-efficient models can help reduce long-term expenses in high-volume production environments.

Finally, durability and maintenance are essential for long-term performance. Choose a CNC foam cutter made from high-quality materials that can withstand continuous use. Regular maintenance is necessary to ensure machine longevity, so check whether the manufacturer provides support for maintenance and replacement parts.

Conclusion

CNC foam cutter machine is an incredibly valuable tool for anyone involved in the creation of foam models, sculptures, packaging, or prototypes. It offers precision, speed, and versatility, allowing you to achieve detailed and intricate designs that would otherwise be difficult to achieve with manual cutting methods. Whether you’re in the arts, manufacturing, or packaging industries, investing in a CNC foam cutter can boost your productivity, reduce waste, and open up new creative possibilities.

By choosing the right CNC foam cutter machine based on your specific requirements, you can ensure that your projects are completed with the highest level of quality and efficiency. From custom foam cutting to large-scale sculpting, this machine is your powerful helper in the world of foam fabrication.

FAQ

1. What types of foam can be cut using a CNC foam cutter?

CNC foam cutters can cut a wide range of foam types, including polystyrene foam, polyurethane foam, EVA foam, and more. The choice of cutter depends on the foam’s density and the desired cutting method.

2. How accurate is CNC foam cutting?

CNC foam cutters offer high precision, with the ability to cut detailed and intricate designs with millimeter accuracy. This ensures consistent results across multiple pieces.

3. Can I use my existing design files for CNC foam cutting?

Yes, CNC foam cutters are compatible with various CAD software programs. You can create your design using CAD software and then upload it directly to the CNC machine.

4. How long does it take to cut foam using a CNC foam cutter?

The cutting time depends on the complexity of the design and the size of the foam. However, CNC foam cutters can work much faster than manual methods, making them ideal for mass production or time-sensitive projects.

5. What maintenance is required for a CNC foam cutter?

Routine maintenance includes cleaning the machine, checking the cutting tools for wear, and lubricating moving parts. Additionally, it’s essential to follow the manufacturer’s recommended maintenance schedule to ensure optimal performance.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.