Blog

Best Used Stone CNC Machines: High-Quality Equipment for work

When it comes to precision stone cutting and engraving, investing in the right equipment is crucial. Stone CNC machines are some of the most advanced tools used in industries such as stonework, monument making, and decorative stone engraving. While new CNC machines can be expensive, high-quality used stone CNC machines offer an excellent alternative for businesses looking to save on costs without compromising on performance.

In this blog, we will discuss the advantages of purchasing used stone CNC machines, what to look for when selecting one, and why CNC stone tools are essential for achieving high precision in stone fabrication.

Why Choose Used Stone CNC Machines?

- Cost Savings:One of the biggest reasons businesses choose used stone CNC machines is cost savings. New machines can cost a significant amount, especially high-performance ones with advanced features. By purchasing used equipment, you can acquire high-quality machines at a fraction of the price, allowing you to allocate funds to other areas of your business.

- Proven Performance:Used CNC machines often come with a history of performance, which can help you assess their reliability. With the right maintenance and care, a well-maintained used stone CNC machine can perform just as well as a new one. Many manufacturers and resellers provide refurbished machines that have been inspected and repaired to meet industry standards.

- Wide Selection:The used market offers a wide range of CNC stone tools and machines, including models that are no longer in production. This gives you access to equipment that may have features unavailable in new machines or that may be better suited to your specific needs.

- Reduced Depreciation:New CNC machines lose their value rapidly as soon as they are purchased. When you buy used equipment, it has already gone through the initial depreciation, meaning you won’t lose as much money when reselling it in the future.

Key Features to Look for in Used Stone CNC Machines

When purchasing used stone CNC machines, it’s essential to pay attention to certain features that will determine the machine’s efficiency, longevity, and suitability for your work.

1. Machine Condition

The condition of the machine is paramount. You want a used machine that has been well-maintained and is still in good working order. Look for evidence of regular maintenance, such as lubricated parts, clean components, and functioning cooling systems. Also, check for any signs of wear and tear, such as rust, broken parts, or loose components.

2. Control System

The CNC machine’s control system is the brain of the operation. It dictates how accurately the machine can follow programmed instructions. Ensure that the machine uses a modern, user-friendly control system, and ask about any software updates or compatibility issues with your existing design programs (like CAD or CAM software).

3. Spindle Power and Speed

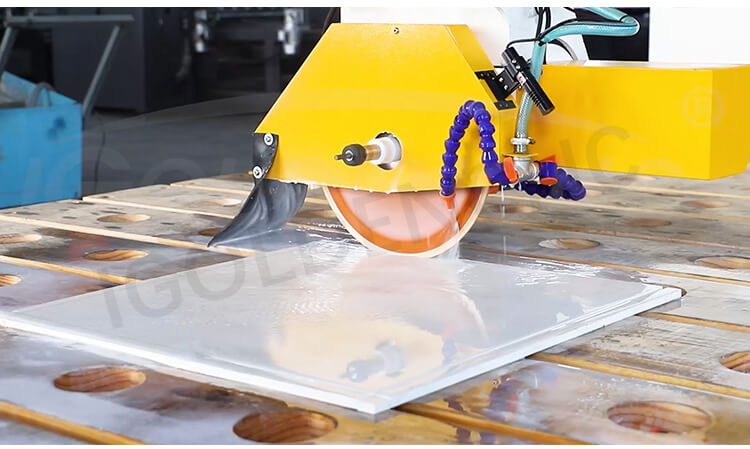

The spindle is one of the most important components of a CNC stone machine. It determines the cutting speed and precision, so you want a spindle with adequate power to handle the materials you’re working with, such as granite, marble, or limestone. Be sure to ask about the spindle’s maximum RPM (rotations per minute) and its general performance.

4. Accuracy and Precision

The primary advantage of CNC machines is their high accuracy and ability to replicate designs with precision. When purchasing a used stone CNC machine, ask for the machine’s tolerance levels. This is the degree of accuracy it can achieve, which directly impacts the quality of the final product.

5. Size and Work Area

Consider the size of the stone you plan to work with. Different machines have different work areas and cutting capacities. Make sure the used stone CNC machine you choose has enough space to handle your typical stone dimensions.

6. Availability of Replacement Parts

Check the availability of replacement parts for the used CNC machine. Some older models may have discontinued parts, which can make repairs costly or difficult. Ensure that the manufacturer still produces or stocks the necessary components.

Advantages of Using CNC Stone Tools

CNC stone tools have revolutionized the stone-cutting industry by providing enhanced accuracy, speed, and flexibility. Here’s why they are indispensable in modern stone fabrication.

1. Precision Cutting and Engraving

CNC stone machines are designed to provide exceptional precision in cutting and engraving. Whether you’re working with delicate designs, intricate carvings, or complex shapes, CNC machines offer a level of accuracy that traditional manual methods simply cannot match.

With the ability to program complex cuts and engravings, CNC routers and milling machines ensure that each piece produced is identical, allowing for consistent results across large runs of products or custom workpieces.

2. Flexibility and Versatility

CNC stone machines can handle a wide variety of tasks, including cutting, shaping, engraving, and polishing. Many CNC stone tools come with multiple tool changers, allowing users to seamlessly switch between cutting, grinding, and polishing tools without stopping the machine. This versatility is crucial for industries like monument-making, where a combination of cuts and engravings may be required in a single piece.

3. Reduced Labor Costs

CNC stone tools automate the cutting and engraving process, reducing the need for skilled labor. Once a design is programmed into the machine, it can run autonomously, cutting down on the time and workforce required for production. This can lead to significant cost savings in labor and a more efficient workflow.

4. Customization

CNC machines enable highly customized work that is difficult to achieve using traditional methods. Whether you need to create custom shapes, logos, inscriptions, or detailed patterns, CNC stone machines allow you to replicate designs with unparalleled precision. This makes CNC technology ideal for monument builders, custom stone fabricators, and interior designers.

5. Higher Production Efficiency

CNC machines can work around the clock, increasing overall production efficiency. With fewer errors and the ability to work unattended, they can complete tasks much faster than manual labor, which is especially important in high-demand environments.

Choosing the Best Used Stone CNC Machines

When looking for the best used CNC stone machines, it’s important to consider your specific needs and business goals. Here are some tips to help guide your decision:

1. Assess Your Business Needs

Consider the type of projects you usually work on and the materials you typically use. Do you need a machine for precision engraving, cutting large slabs of stone, or creating intricate designs? The machine’s capabilities should align with your needs.

2. Research the Brand and Model

Some brands have a better reputation for reliability and longevity than others. Research the manufacturers and their product lines to ensure you’re purchasing a machine from a trusted source.

3. Inspect the Machine

If possible, inspect the machine in person before purchasing. Look for any signs of wear, check the alignment of the components, and test the functionality of the control system and spindle.

4. Consider Refurbished Machines

Consider buying a refurbished CNC stone machine. Refurbished machines are often restored to like-new condition, with updated parts and tested functionality, offering a great compromise between new and used.

5. Warranty and Support

Many sellers of used stone CNC machines offer warranties or maintenance packages. This can be invaluable in case any issues arise after purchase. Ensure you understand the terms of the warranty before finalizing the sale.

Conclusion

Used stone CNC machines are a cost-effective solution for businesses in need of high-quality, precise stone cutting, engraving, and shaping tools. By carefully selecting the right machine, considering your business needs, and understanding the key features to look for, you can maximize your investment in used CNC stone tools.

With CNC technology, you’ll benefit from precision, flexibility, and efficiency, whether you’re working on custom stone carvings, monuments, or other stone fabrication projects. Invest in the right used stone CNC machine and elevate your stonework to new levels of creativity and quality.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.