Blog

Best CNC Stone Router for Complex and Detailed Stone Engraving

Stone engraving is a meticulous and intricate process that requires both skill and the right equipment. Whether you are working with marble, granite, limestone, or engineered stones like quartz, a high-quality CNC stone router can significantly improve your efficiency and precision. In this blog post, we will explore what makes a CNC stone router the best option for complex and detailed stone engraving, highlight key features, and help you understand how to choose the right router for your needs.

What Is a CNC Stone Router?

A CNC stone router is a computer-controlled machine used for engraving, cutting, and shaping stone materials. The router is equipped with a rotating tool or spindle, which moves along multiple axes (typically 3 to 5), allowing for precise carving and engraving of stones. These machines are capable of executing detailed patterns, creating artistic sculptures, and even cutting large slabs of stone to fit specific requirements.

The CNC technology ensures that the cutting process is highly accurate, reducing human error and enabling operators to execute complex designs with ease. Whether you’re engraving detailed images on granite or cutting intricate patterns on marble, a CNC stone router ensures that every cut is precise and consistent.

Key Features of the Best CNC Stone Routers

When choosing the best CNC stone machine, several features must be taken into consideration. These features contribute to the router’s ability to handle complex stone engraving tasks and offer high precision and efficiency.

1. Multi-Axis Control

The most advanced CNC stone routers come with multi-axis capabilities, usually between 3 to 5 axes. These machines provide a greater level of flexibility, enabling them to work on more intricate designs. Multi-axis control allows for cutting and engraving from different angles and orientations, making it easier to produce highly detailed and complex designs. For example, 5-axis machines can move the tool along the X, Y, and Z axes, as well as tilt the tool and rotate the material, which is essential for detailed stone carving.

2. High-Speed Spindle

The spindle is the heart of a CNC stone router. A high-speed spindle allows for faster cutting, smoother engraving, and longer tool life. In stonework, the spindle’s speed is crucial for maintaining consistent performance when cutting through hard materials like granite or marble. Spindles with variable speed control can also help manage different stone types, allowing you to adjust the speed according to the hardness of the material.

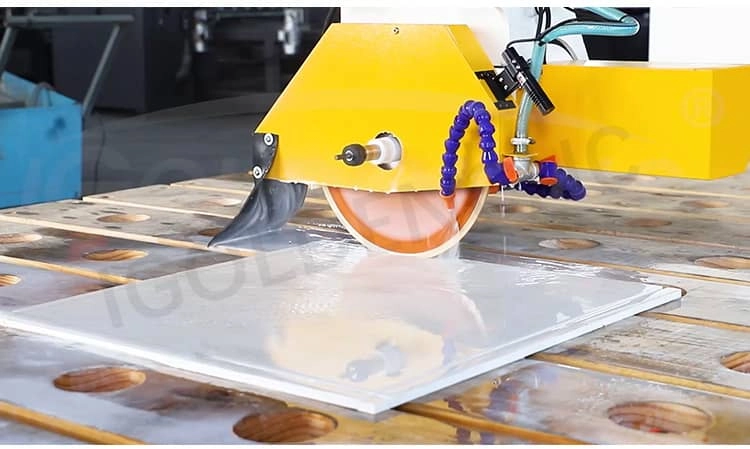

3. Water Cooling System

Cutting and engraving stone generates significant heat, which can cause the tools to wear out prematurely and the material to crack. A CNC stone router equipped with a water cooling system ensures that the tools and materials stay cool during operation. The cooling system helps improve tool life, maintain cutting accuracy, and prevent the overheating that might result in cracks or damage to the stone.

4. Diamond Tools and Bits

To achieve the high precision required for detailed stone engraving, the best CNC stone routers use diamond-coated tools and bits. Diamond tools are hard and durable, allowing for clean and precise cuts in tough materials. They stay sharp longer than traditional tools, reducing the need for frequent tool changes and improving overall efficiency.

5. User-Friendly Software Integration

A major advantage of CNC technology is its ability to integrate seamlessly with design software. The best CNC stone routers are compatible with popular CAD/CAM software programs like AutoCAD, Alphacam, or ArtCAM. This allows operators to design intricate patterns and directly upload the files to the machine for cutting. With advanced software, operators can easily adjust designs, manage cutting paths, and execute detailed engravings.

6. Precision and Accuracy

Accuracy is one of the most important factors when it comes to CNC stone routers. The best machines are designed to provide high precision, ensuring that every cut or engraving is executed with exact measurements. These routers use fine-tuned motors and advanced technology to maintain consistent results. For projects that require tight tolerances, such as memorial engravings or intricate stone sculptures, this level of precision is crucial.

Benefits of Using a CNC Stone Router for Stone Engraving

The advantages of using a CNC stone router are substantial, particularly for businesses involved in stone cutting, engraving, and fabrication. Let’s take a look at some of the key benefits:

1. Enhanced Efficiency

Manual stone engraving can be time-consuming and labor-intensive. With a CNC stone router, you can speed up the engraving process while maintaining high levels of accuracy. Automated cutting and engraving reduce the amount of human labor required, allowing businesses to increase output and meet tight deadlines. The machine can run continuously for long hours, which leads to faster turnaround times for clients.

2. Consistent Quality

One of the major challenges of manual stone engraving is the inconsistency in quality. Human errors, such as misalignment or uneven cuts, can occur during the process. However, CNC stone routers ensure that every piece is cut or engraved exactly as specified, with no variation between each product. This consistency is particularly important for businesses that deal with large quantities of custom orders or require high-quality, uniform products.

3. Complex and Detailed Designs

CNC stone routers excel at executing intricate and detailed designs that would be difficult or impossible to achieve manually. With the ability to work with complex CAD files and multiple axes of motion, these routers can create elaborate patterns, curves, and textures with high precision. Whether you’re engraving logos, personalized messages, or fine artwork on stone, a CNC stone router provides the versatility and precision needed for these complex tasks.

4. Reduced Material Waste

CNC stone routers help reduce material waste through optimized cutting paths. Unlike manual cutting, where mistakes can lead to wasted stone, CNC machines ensure every cut is efficient. The software helps operators plan cutting patterns that minimize waste, saving you money on materials and improving the overall profitability of the business.

5. Cost-Effectiveness

While the initial investment in a CNC stone router may be higher than traditional stone cutting equipment, the long-term benefits outweigh the costs. CNC routers reduce labor costs, increase production speed, and lower the likelihood of costly mistakes. Over time, the machine pays for itself through improved efficiency, reduced waste, and faster project completion.

Applications of CNC Stone Machining Center

The versatility of CNC stone routers makes them suitable for a wide range of applications. Here are some of the most common uses in the stone industry:

Countertop Fabrication

CNC routers are widely used in the production of granite, marble, and quartz countertops. These machines can easily cut and shape large stone slabs, create sink cutouts, and produce edge profiles.

Monument and Gravestone Engraving

CNC stone routers are perfect for engraving tombstones, memorial plaques, and other types of monuments. Their precision allows for highly detailed engravings, ensuring that every name, date, and design is perfectly executed.

Architectural Stonework

In architecture, CNC routers are used to create intricate stone elements, such as columns, arches, tiles, and decorative features. These machines can precisely cut and shape stone for a wide range of applications in both residential and commercial projects.

Stone Sculpting

Artists and sculptors use CNC routers to create detailed stone sculptures. The high precision of these machines enables the carving of fine details, bringing artistic visions to life with remarkable accuracy.

Choosing the Best CNC Stone Router

Selecting the best CNC stone router for your business requires careful consideration of several factors:

- Material Compatibility: Ensure the router can handle the types of stone you typically work with, including granite, marble, and quartz.

- Machine Size: Consider the size of the stone slabs you plan to work with. The router should have a sufficient worktable to accommodate larger pieces.

- Software Compatibility: Look for routers that integrate well with your design software, allowing for easy file transfers and design adjustments.

- Precision and Speed: Choose a machine that offers the precision needed for detailed engravings while maintaining a fast cutting speed for large projects.

- Budget: Balance the machine’s features with your budget. While high-end models may offer advanced features, they should provide value through increased efficiency and reduced labor costs.

A CNC stone router is an essential tool for any business involved in stone cutting or engraving. With its ability to produce intricate designs, increase production efficiency, and deliver consistent quality, the best CNC routers provide a significant competitive advantage. Whether you are fabricating countertops, creating memorial stones, or working on architectural projects, investing in a high-quality CNC stone router will help you achieve better results and higher profits.

For businesses looking for the best CNC stone routers, IGOLDENCNC offers a range of reliable machines that combine precision, speed, and versatility. With advanced features like multi-axis control and diamond tools, IGOLDENCNC ensures that you can handle even the most complex stone engraving tasks with ease.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.