Blog

Precision CNC Router Machining Center for Material Processing

In today’s industrial world, precision and efficiency are key to staying ahead in competitive markets. Whether it’s cutting, shaping, or engraving, a CNC router machining center is a game-changing tool for manufacturers in various industries. These systems are designed to automate material processing, significantly improving both the quality and speed of production.

In this blog, we will explore the benefits of CNC router machining centers, how they are used for material processing, and why they are crucial to a wide range of industries such as woodworking, metalworking, stone processing, and more.

What is a CNC Router Machining Center?

CNC router machining center is an advanced automated tool used for cutting, drilling, carving, and engraving materials with high precision. The “CNC” stands for Computer Numerical Control, meaning the machine is controlled by a computer system that uses pre-programmed commands to guide the machining process.

These machining centers are versatile, capable of processing a variety of materials, including wood, metals, plastics, and stone. Whether you’re creating intricate designs or high-volume parts, the CNC router center provides unmatched accuracy and repeatability, making it an essential tool in modern manufacturing.

Benefits of Using a CNC Router Machining Center

1. Unmatched Precision and Accuracy

One of the primary advantages of a CNC router machining center is its precision. By utilizing a computer-controlled system, these machines can follow exact measurements and designs with incredible accuracy. This level of precision is critical in industries where minute details can make a significant difference, such as in aerospace, automotive, and stone carving.

For example, a CNC router machining center can achieve tolerances as tight as 0.01mm, ensuring that each part or design is identical, even with large-scale production.

2. Increased Efficiency and Productivity

CNC routers are designed for speed. Since the machine is automated, the time spent manually guiding the tool or adjusting settings is minimized. This leads to faster production cycles, allowing businesses to complete more projects in less time.

Moreover, CNC router machining centers can run continuously, 24/7, with minimal supervision. This maximizes output while reducing labor costs and human error.

3. Versatility in Material Processing

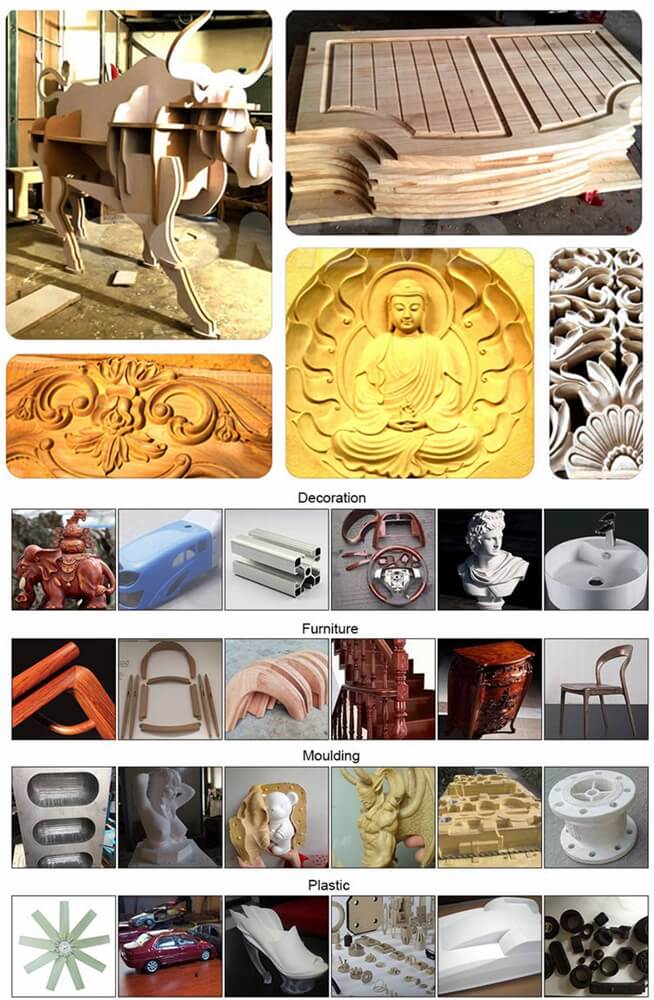

A CNC router machining center is not limited to one material. It can process a wide range of materials, making it versatile enough for multiple industries. From hardwoods and softwoods to metals and stone, the machine can handle different materials efficiently.

This versatility is particularly useful for businesses that serve a variety of sectors, such as woodworking for furniture and cabinetry, sign-making for engraving, and even stonework for monuments or gravestones.

4. Complex Designs with Ease

CNC router machining centers excel at producing intricate designs and details that would be difficult or impossible with traditional manual methods. With the aid of advanced CAD (Computer-Aided Design) software, designers can create complex patterns, 3D shapes, and highly detailed carvings.

Whether it’s creating custom furniture designs, cutting elaborate patterns into metal, or engraving personalized messages on a stone monument, CNC machining centers allow manufacturers to turn even the most complex ideas into reality.

How CNC Router Machining Centers Are Used in Various Industries

Woodworking

In the woodworking industry, CNC router machining centers are essential tools for creating intricate designs and custom-made furniture. These machines can cut, shape, and carve wood with incredible precision, which is important when producing detailed furniture pieces, cabinetry, or decorative accents. CNC routers are also ideal for mass-producing identical parts, such as panels, moldings, and cabinet doors.

Metalworking

CNC routers can also be used to process metals such as aluminum, steel, and brass. These machines offer high-speed cutting, enabling manufacturers to create custom metal parts with ease. The CNC router machining center’s ability to precisely cut complex shapes and patterns makes it a go-to tool in the automotive, aerospace, and electronics industries.

Stone Processing

For businesses working in stone processing, a CNC router machining center can perform detailed cutting and engraving tasks on materials like granite, marble, and limestone. This is particularly useful in the monument-making and stone sculpture industries, where precision and intricate detailing are essential. Whether it’s carving text into a tombstone or sculpting a stone sculpture, CNC routers can handle the job with high accuracy.

Plastic and Composite Materials

CNC routers can also cut and shape various types of plastics and composites. In industries such as signage, packaging, and electronics, the ability to precisely carve or cut plastic components is essential for both aesthetic and functional purposes.

Choosing the Right CNC Router Machining Center for Your Business

When selecting a CNC router machining center, it’s important to consider several factors to ensure you’re investing in the right machine for your needs:

1. Material Compatibility

Not all CNC routers are capable of processing all materials. Some are better suited for softer materials like wood or plastic, while others are designed to handle harder materials like metal or stone. Be sure to choose a machine that is compatible with the materials you intend to process.

2. Machine Size and Workspace

Consider the size of the parts you will be working with. Some CNC routers have larger work areas and can handle big pieces of material, while others are more compact. Make sure the machine you choose fits your space and can handle your typical project sizes.

3. Speed and Efficiency

CNC routers vary in terms of speed, and it’s important to find a machine that can meet your production requirements. Faster machines can help increase productivity, especially when working with large volumes of parts.

4. Control and Software Integration

CNC router machining centers use software to control the machines. It’s important to choose a machine that integrates well with the software you are familiar with or the one that offers the features you need. Popular CNC software options include VCarve, Alphacam, and Mastercam.

FAQ

1. What materials can a CNC router machining center handle?

CNC router machining centers are versatile and can process a wide range of materials such as wood, metals (e.g., aluminum, steel), plastics, composites, and stone (granite, marble). The ability to handle these different materials makes them suitable for industries like woodworking, metalworking, signage, stone carving, and more.

2. How does a CNC router center improve production?

A CNC router machining center improves production by automating processes that would otherwise require manual labor. This leads to faster, more precise work, reducing the chances of human error. It also allows for consistent quality and can run 24/7, increasing output while lowering labor costs and improving efficiency.

3. How do I choose the right CNC router center for my business?

When selecting a CNC router center, consider factors like the materials you need to process, the machine’s size and workspace, speed, software compatibility, and your production requirements. Ensure the machine can handle the materials you work with and that it offers the features you need for your business’s projects.

Maintenance and Longevity of CNC Router Machining Centers

To ensure that your CNC router machining center performs optimally over time, regular maintenance is essential. This includes routine tasks like cleaning, lubricating moving parts, checking the machine’s alignment, and ensuring that the electrical system is functioning properly. Most manufacturers also recommend periodic training for operators to ensure that the machine is used effectively and safely.

By adhering to maintenance schedules, businesses can extend the life of their machines, reduce downtime, and avoid costly repairs. Investing in a high-quality CNC router machining center is a long-term investment that, when properly maintained, can deliver years of reliable service.

Conclusion

The CNC router machining center is an essential tool in modern manufacturing, offering unmatched precision, versatility, and efficiency across a wide range of industries. Whether you’re working with wood, metal, stone, or plastic, CNC routers enable complex designs, high-speed processing, and consistent quality. By selecting the right machine for your needs and maintaining it properly, you can optimize your production and stay competitive in your field.

Invest in a high-quality CNC router machining center to elevate your material processing capabilities and take your business to the next level.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.