Blog

Best CNC Stone Carving Tools for Granite, Marble, and Stonework

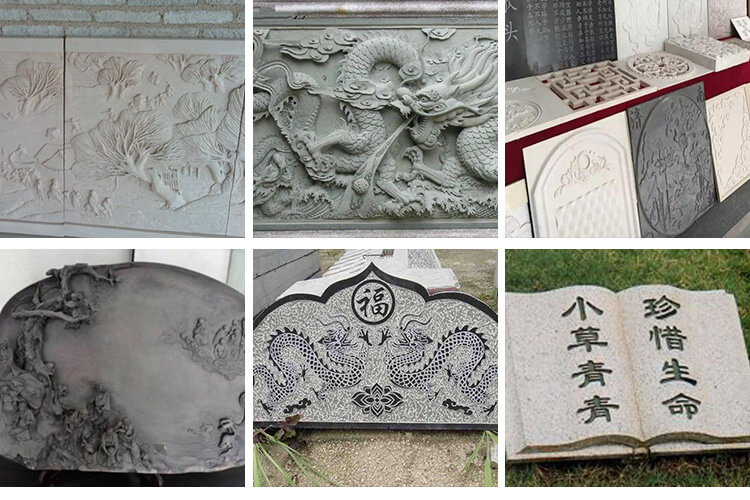

CNC stone carving tools have revolutionized the way stones like granite, marble, and other materials are carved, engraved, and shaped. Whether you’re working on intricate designs for sculptures, tombstones, countertops, or architectural elements, having the right CNC stone carving tools is essential to achieving high-quality results. These tools not only ensure precision but also make the carving process more efficient and less labor-intensive.

In this blog, we’ll explore the best CNC stone carving tools available, focusing on their specific features, benefits, and ideal applications. From diamond-tipped bits to multi-axis CNC routers, we’ll cover everything you need to know to enhance your stoneworking capabilities.

Understanding CNC Stone Carving Tools

Types of CNC Stone Carving Tools

The CNC stone carving tools you choose depend on the type of stone you’re working with, the complexity of your design, and the capabilities of your machine. Here are some of the most commonly used tools for stone carving:

1. Diamond-Coated Bits

Diamond-coated bits are among the most popular and durable tools for carving hard stones like granite and marble. Industrial-grade diamonds embed themselves in these bits, providing exceptional hardness and wear resistance and making the bits ideal for cutting through tough materials. Diamond-coated bits function in both rough cutting and fine engraving, offering smooth, precise cuts.

- Benefits: Longer tool life, faster cutting speeds, and cleaner cuts.

- Best for: Fine detail engraving, sculpture carving, and general cutting.

2. Tungsten Carbide Tools

Tungsten carbide tools are known for their strength and sharpness.These tools are commonly used by stone carvers in CNC stone carving for tasks involving heavy material removal, such as rough shaping.High levels of pressure can be withstood by tungsten carbide, making it a great choice for harder stones like granite and marble.

- Benefits: High durability and performance, especially for rough carving and shaping.

- Best for: Rough stone shaping, large-scale carving, and initial cuts.

3. Fluted Router Bits

Carvers use fluted router bits for fine detail carving and smooth finishing on stone surfaces. The fluted design reduces heat buildup and prevents the tool from getting clogged with debris.These bits are especially useful for achieving detailed carvings and are perfect for texturing and contouring.

- Benefits: Smooth, detailed cuts with minimal vibration.

- Best for: Fine engraving, surface texturing, and contour carving.

4. Ball Nose Bits

Ball nose bits are essential for 3D carving and achieving rounded, smooth surfaces on stone. These tools are perfect for applications that require carving into complex contours or creating rounded edges. They are ideal for creating intricate details, like leaves, faces, or other detailed textures.

- Benefits: Ability to carve smooth curves and detailed 3D features.

- Best for: 3D engraving, relief carvings, and detailed stone sculptures.

5. V-Bits

V-Bits are often used for lettering and engraving. Their unique V-shaped design allows them to carve clean, sharp lines and precise letters into stone surfaces. V-Bits are often used to create inscriptions on gravestones, plaques, or any stonework that requires legible text.

- Benefits: Clear, precise carvings and letterings.

- Best for: Lettering, number engraving, and simple logos or designs.

6. Chamfer Bits

Chamfer bits are used to create beveled edges on stone surfaces, often providing a polished and finished look. These bits are ideal for creating sloped edges on stones, making them a good choice for architectural applications or decorative stonework.

- Benefits: Creates beveled, smooth edges on stone surfaces.

- Best for: Edge finishing, architectural detailing, and stone borders.

Features to Look for in CNC Stone Carving Tools

When choosing CNC stone carving tools, several features should be taken into consideration to ensure that you get the best performance for your projects:

1. Durability

Stones like granite and marble are tough materials that can quickly wear down low-quality tools. Therefore, it’s essential to invest in high-quality carving tools that can withstand the pressure of carving hard materials without wearing out quickly. Diamond-coated tools and tungsten carbide tools are among the most durable options available.

2. Compatibility with CNC Machines

Make sure that the CNC stone carving tools you choose are compatible with the specific type of machine you are using. Some tools are designed specifically for 3-axis CNC routers, while others are suitable for more advanced 5-axis machines. Always verify the specifications to ensure the tool will fit your machine and work seamlessly.

3. Tool Geometry and Design

The geometry of the carving tool affects the quality of the cut. For instance, V-Bits have a sharp point that allows for precise text and engraving, while ball nose bits are designed for smoother, rounded cuts. Fluted bits help remove material efficiently while reducing heat, and diamond bits are ideal for achieving smooth, fine carvings on dense stones.

4. Heat Resistance

Stone carving generates a lot of heat, especially when cutting through dense materials. High-quality carving tools should be resistant to heat to avoid distortion or premature wear. Tools with specialized cooling features or coatings, such as diamond coating, are designed to handle high temperatures during prolonged use.

Top CNC Stone Carving Machines for Professional Use

Alongside choosing the right tools, selecting a high-quality CNC stone machine is essential for achieving professional results. Here are some top CNC stone carving machines that are well-suited for carving granite, marble, and other types of stone:

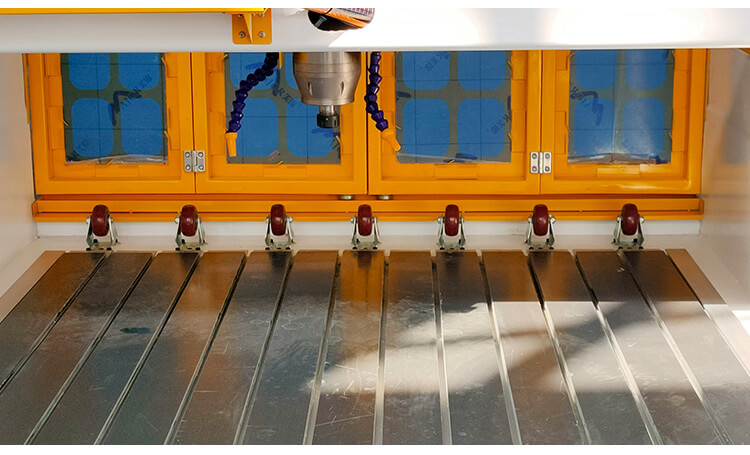

1. IGOLDENCNC 4-Axis CNC Stone Carving Machine

The IGOLDENCNC 4-Axis CNC Stone Carving Machine is designed for high-precision carving and engraving of stones like granite and marble. It features advanced software integration, a robust spindle, and multi-axis control, making it perfect for detailed stonework. With the ability to handle heavy materials, this machine is ideal for both large and small projects.

2. Biesse Rover CNC Router

The Biesse Rover is a reliable and efficient machine that combines speed with precision. It is equipped with powerful tools for stonework and supports both 3-axis and 4-axis carving. This CNC router is perfect for creating detailed 3D carvings and is compatible with a variety of stone carving tools for diverse applications.

3. CMS Brembana Maxima CNC Router

Another high-end CNC stone router, the CMS Brembana Maxima, designed for professionals, shows its versatility and ability to handle large slabs of stone. The Maxima CNC provides excellent stability and precision, making it perfect for fine detailing and custom engraving on granite, marble, and other stone surfaces.

Conclusion

Choosing the best CNC stone carving tools is essential for ensuring high-quality results in stonework. Whether you are working on custom memorials, sculptures, or architectural elements, the right tools will make the carving process more efficient and precise. Diamond-coated tools, tungsten carbide tools, and V-bits are among the top choices for working with tough materials like granite and marble. By selecting durable, high-performance tools and pairing them with the right CNC machine, you can achieve intricate, long-lasting stone carvings for any application.

When you invest in high-quality CNC stone carving tools, you ensure that your stonework meets the highest standards of precision and artistry, helping you deliver exceptional results for your clients.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.