Blog

Best Wholesale 3 Axis Stone CNC Router for Marble & Granite

In the stone fabrication industry, precision, speed, and versatility are paramount. Whether you’re crafting intricate designs for monuments or cutting large slabs of marble and granite, having the right equipment can make all the difference. One of the most essential tools for this job is the wholesale 3 axis stone CNC router.

This blog explores the best wholesale 3 axis stone CNC router for working with marble, granite, and other stones. We will discuss the benefits, key features, and why investing in a wholesale 3-axis CNC router can help streamline your stone processing operations.

What Is a 3-Axis Stone CNC Router?

A 3-axis stone CNC router is a machine used for cutting, engraving, and shaping stones like marble, granite, and limestone. The term “3-axis” refers to the three primary movements of the tool: X-axis, Y-axis, and Z-axis. These axes enable the router to move across the stone’s surface in three dimensions, allowing for intricate cuts, carvings, and shapes.

The X-axis controls left and right movements, the Y-axis controls forward and backward movements, and the Z-axis controls up and down movements. Together, these movements give the router the ability to create highly detailed and precise patterns and designs.

Why Choose a 3-Axis CNC Router for Stone Fabrication?

There are several reasons why 3-axis CNC routers are an excellent choice for stone fabrication, particularly when working with hard materials like marble and granite.

1. Precision and Accuracy

The precision of a stone CNC router is one of its most significant advantages. With digital control systems and advanced programming, these routers can achieve accuracy to within fractions of a millimeter. This level of detail is crucial for creating high-quality stone products, whether you’re making tombstones, countertops, or custom carvings.

2. Efficiency and Speed

Compared to manual stone cutting methods, a 3-axis CNC router can significantly increase production speed. These machines can operate 24/7 with minimal downtime, allowing businesses to complete large volumes of work quickly and efficiently. As a result, you can take on more projects and reduce turnaround times.

3. Consistency and Repeatability

Another benefit of 3-axis CNC routers is their ability to replicate designs with consistent quality. Once a design is programmed into the machine, it can produce the same result repeatedly without any variations. This is particularly beneficial for businesses that need to produce multiple pieces with identical designs, such as customized stone plaques or commercial countertops.

4. Complexity in Design

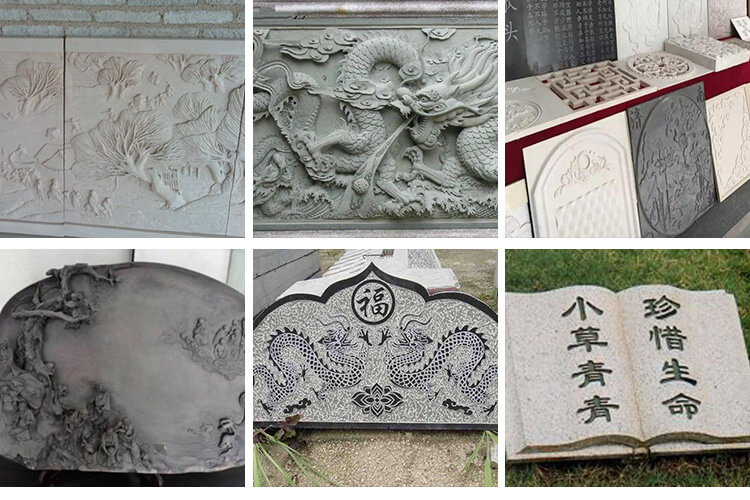

With a 3-axis stone CNC router, you can create highly complex and intricate designs that would be time-consuming or impossible with traditional hand tools. From engraving detailed images to cutting complex shapes, these machines provide the flexibility to craft customized stone products with ease.

5. Reduced Labor Costs

By automating much of the cutting and engraving process, 3-axis CNC routers reduce the need for manual labor. This results in lower operational costs, freeing up resources for other areas of the business. Moreover, CNC routers require less skilled labor than traditional methods, making them easier to operate and maintain.

Key Features of the Best Wholesale 3-Axis Stone CNC Routers

When considering wholesale CNC machines, it’s important to evaluate their features and specifications to ensure they meet your needs. Here are some key features to look for:

1. Spindle Power and Speed

The spindle is one of the most critical components of a CNC router. It directly impacts the cutting speed and precision. For stone cutting, you need a powerful spindle capable of handling tough materials like granite and marble. A high-speed spindle allows for faster cutting while maintaining precision.

2. Control System

A robust and user-friendly control system is essential for programming the machine and managing operations. The best 3-axis CNC routers come equipped with advanced control systems that can handle complex designs and automated operations. Common control systems include Siemens, Fagor, and Fanuc, which are known for their precision and ease of use.

3. Tool Changing Mechanism

Some 3-axis CNC routers come with an automatic tool changer (ATC), allowing for seamless switching between tools during the cutting process. This feature saves time and helps maintain production efficiency by reducing manual intervention.

4. Cutting Area and Dimensions

The cutting area refers to the size of the stone slab the router can handle. A larger cutting area means you can work with bigger pieces of stone without the need for repositioning. Ensure that the machine’s cutting area matches your typical project requirements.

5. Dust Collection System

Stone cutting generates a significant amount of dust, especially when working with materials like granite. A dust collection system is essential for keeping the work environment clean and safe. It helps maintain visibility and prevents the accumulation of harmful particles that can affect the machine’s performance.

6. Water Cooling System

Cutting through hard stones generates heat, which can cause wear and tear on the tools and affect the material. A water cooling system helps keep the tools cool, preventing overheating and ensuring a smooth cutting process.

Benefits of Purchasing Wholesale 3-Axis CNC Routers

1. Cost-Effective Investment

Buying wholesale 3-axis CNC routers can significantly reduce costs compared to purchasing individual units. Wholesale purchases often come with discounts or bulk pricing, making them a more affordable option for businesses looking to expand their operations or replace outdated equipment.

2. Increased Production Capacity

With a wholesale 3-axis CNC router, you can ramp up your production capacity without sacrificing quality. These machines allow you to take on larger projects and increase your throughput, helping you meet the growing demands of your clients.

3. Access to High-Quality Equipment

Wholesale purchases often come with access to top-tier equipment at a competitive price. This ensures that your business has access to high-quality, durable CNC routers that can handle tough stone materials like granite and marble, ensuring long-term reliability and minimal downtime.

Choosing the Right Wholesale 3-Axis CNC Router for Your Needs

When choosing a wholesale 3-axis CNC router, it’s important to evaluate several factors to ensure it aligns with your business requirements:

- Project Scope: Consider the size and complexity of the projects you typically work on. If you handle large stone slabs, you will need a router with a larger cutting area.

- Machine Features: Ensure the machine offers the key features you need, such as a powerful spindle, an automatic tool changer, and a dust collection system.

- After-Sales Support: Consider the level of after-sales support provided by the manufacturer or supplier. Good customer service, training, and maintenance options are essential for maximizing the lifespan of the machine.

- Warranty: Check if the machine comes with a warranty, which can give you peace of mind and protection in case of technical issues.

Conclusion

A wholesale 3-axis CNC router is an invaluable tool for stone fabricators working with marble, granite, and other stones. These machines provide precision, speed, and versatility, enabling businesses to produce high-quality products efficiently. By purchasing wholesale, you can save money and gain access to top-tier equipment without compromising on performance.

Whether you are involved in monument making, custom stone engraving, or large-scale stone fabrication, investing in a high-quality 3-axis CNC stone router will help you elevate your operations and stay competitive in the stone industry.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.