Blog

CNC Router Machining: Ideal for Custom Fabrication and Design

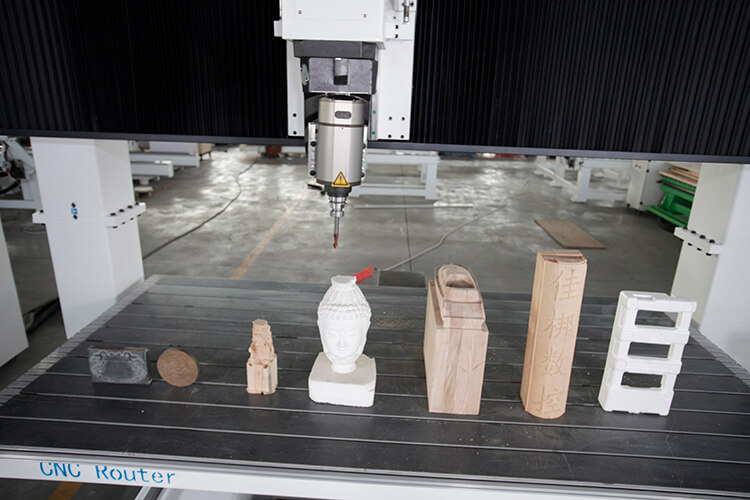

CNC router machining is a game-changing technology that has transformed industries requiring high precision, custom design, and efficient production. With its ability to cut, carve, and engrave a variety of materials including wood, metal, plastics, and composites, CNC routers have become essential in many sectors. Whether you’re in woodworking, metal fabrication, or sign making, this versatile tool can enhance your production capabilities and improve your business outcomes.

In this blog post, we’ll dive into CNC router machining, its features, applications, benefits, and why it’s the ideal choice for custom fabrication and design.

What is CNC Router Machining?

CNC (Computer Numerical Control) router machining is an automated manufacturing process that uses a computer-controlled machine to cut, carve, and shape materials based on programmed designs. Unlike manual routers, which require human intervention, CNC routers are fully automated and can execute highly detailed tasks with precision and consistency.

The CNC router machine is typically equipped with a cutting tool (often referred to as a spindle) that moves along multiple axes to shape or carve a material into the desired design. The machine is controlled via a computer interface, where users can upload a CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing) file containing the machining instructions.

Key Features of CNC Router Machining

- Precision and Accuracy:One of the primary benefits of CNC router machining is its ability to deliver precision cutting and carving. Unlike manual processes, CNC routers are highly accurate, ensuring that each piece is consistent and within the exact specifications, even for complex designs.

- Versatile Material Compatibility:CNC routers are capable of machining a wide variety of materials. Whether it’s softwood, hardwood, plastic, metal, or composite materials, CNC routers can handle them with ease. This versatility makes CNC routers suitable for multiple industries, from woodworking and automotive to aerospace and sign making.

- Multi-Axis Movement:CNC routers come in different axis configurations, including 3-axis, 4-axis, and 5-axis machines. The additional axes allow for more intricate designs and greater flexibility in machining, enabling the router to carve, shape, and cut materials at multiple angles.

- User-Friendly Software:Modern CNC router machines come with intuitive software that simplifies the design process. Many machines are compatible with popular CAD and CAM programs, allowing users to create and modify their designs directly within the software before running them on the CNC machine.

Applications of CNC Router Machining

The versatility of CNC router machining makes it applicable across a wide range of industries. Here are some common uses:

1. Woodworking and Furniture Making

CNC routers are widely used in woodworking to create detailed furniture pieces, cabinetry, decorative panels, and intricate wood carvings. They can easily cut through both soft and hardwoods, making them ideal for creating custom designs, joins, and unique patterns.

2. Sign Making and Advertising

CNC routers are commonly used to create custom signs, logos, and displays. Whether it’s cutting letters, logos, or shapes from materials like wood, acrylic, or metal, CNC routers can produce highly detailed and precise engravings, making them ideal for sign-making businesses.

3. Prototyping and Product Design

In the product design industry, CNC routers allow designers to create prototypes with high accuracy and speed. Whether it’s a model or a fully functional prototype, CNC routers enable rapid prototyping, helping designers test and refine their ideas before moving to mass production.

4. Metal Fabrication

CNC routers are also used in metalworking, particularly in the aerospace, automotive, and construction industries. These machines can cut and shape metal sheets, profiles, and plates, providing a high degree of accuracy in parts manufacturing.

5. Custom Engraving

CNC routers can engrave a wide variety of materials, such as metal, wood, and plastic, with intricate designs and patterns. This makes them a popular choice for engraving logos, serial numbers, or artistic patterns on products or surfaces.

Benefits of CNC Router Machining

Investing in a CNC router for your business can provide a range of advantages:

1. High Precision and Consistency

The precision offered by CNC routers is unmatched, allowing businesses to produce identical pieces consistently. Whether you need to produce one part or a thousand, CNC router machining ensures each piece is of equal quality.

2. Increased Productivity

CNC routers can work continuously, 24/7, without needing breaks or human intervention. This boosts productivity, especially in high-volume production settings, and reduces labor costs.

3. Complex Designs Made Easy

CNC router machines are ideal for creating intricate designs that would be challenging to achieve manually. The advanced software control allows you to program complex patterns, shapes, and carvings that are executed precisely.

4. Customization

With CNC router machining, businesses can easily offer custom solutions for clients. Whether it’s custom cabinetry, signage, or a specialized product, the ability to design and produce unique items on demand is one of the main benefits of CNC machining.

5. Cost Savings

Although CNC routers represent a significant initial investment, they can save money in the long run by reducing material waste, speeding up production times, and reducing the need for manual labor. The cost per piece decreases significantly with high-volume production.

Choosing the Right CNC Router for Your Business

When selecting a CNC router for your business, several factors should be taken into consideration:

1. Size and Work Area

Determine the size of the workpieces you’ll be cutting or carving. CNC routers come in various sizes, from compact tabletop models for smaller projects to larger machines capable of handling big sheets of material.

2. Axis Configuration

Consider how complex your designs are. A 3-axis router will suffice for simple cutting and shaping, but for more intricate work like engraving or multi-dimensional carving, a 4-axis or 5-axis CNC router would be more suitable.

3. Spindle Power and Speed

For high-volume production or tougher materials, a router with a more powerful spindle will be necessary. Look for a spindle with adequate speed and torque to handle the types of materials you’ll be working with.

4. Software Compatibility

Ensure the CNC router machine is compatible with the design software you use, such as AutoCAD, Fusion 360, or SolidWorks. Ease of use and integration with software will save time and reduce mistakes during production.

5. Budget

CNC routers come in a range of prices. While high-end models offer more advanced features, they also come with a higher price tag. Consider your budget and the specific requirements of your projects when selecting a machine.

Safety Precautions

Before diving into the intricate world of CNC routing, it’s crucial to prioritize safety before proceeding to any machine operation. Here are some essential safety precautions you need to keep in mind:

1. Read the User Manual

Familiarize yourself with the manufacturer’s guidelines and recommendations in the user manual. Pay special attention to your CNC router model’s safety instructions and operational procedures.

2. Wear Appropriate Personal Protective Equipment (PPE)

Always wear safety glasses to protect your eyes from flying debris.

Use hearing protection, especially if your CNC router generates high noise levels. In addition, wear appropriate clothing, including closed-toe shoes and snug-fitting garments, to prevent entanglement with moving parts.

3. Secure the Workspace

Ensure the work area is well-lit and clutter-free to prevent tripping hazards. Establish clear pathways and emergency exits in case of unforeseen events. Keep bystanders away from the operating machine.

4. Check and Maintain Tools

Regularly inspect and maintain cutting tools and ensure the toolpath is clear and free of any obstructions before starting the CNC router. Replace worn-out or damaged tools promptly to prevent accidents and maintain cutting precision.

5. Material Setup

Be sure to securely fasten the material you will be working on to the router bed using appropriate clamps or fixturing devices. Double-check material dimensions to avoid collisions and ensure accurate cutting.

6. Emergency Stop Procedures

There will be times when you must immediately stop any production process already underway for safety and other reasons. Familiarize yourself with the emergency stop system of your machine. As you review the CNC router tutorial in the user’s guide, test the emergency stop feature before starting any operation to ensure its immediate effectiveness.

7. Dust Collection System

Many CNC routers will include a dust collection system to minimize airborne particles and maintain a clean workspace. Empty and clean the dust collector regularly to prevent clogs and maintain optimal performance.

8. Power Supply and Connections

Finally, ensure the CNC router is properly grounded before cutting to prevent electrical hazards. Regularly inspect power cords and connections for any signs of wear or damage before using your machine.

Adhering to these safety precautions sets the foundation for safety on your production floor. In the subsequent sections of this guide, we’ll delve into the step-by-step process of setting up and operating your CNC router, exploring its full potential while keeping safety at the forefront of your workflow.

Conclusion

CNC router machining has proven itself as one of the most effective methods for precision cutting, shaping, and engraving. From woodworking and metal fabrication to sign making and custom product design, CNC routers enable businesses to achieve high precision, efficiency, and customization.

Whether you’re a small business owner or a large-scale manufacturer, a CNC router can significantly improve your production process, reduce waste, and provide the flexibility needed to tackle complex designs. Invest in CNC router machining today to stay ahead of the competition and unlock new creative possibilities for your business.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.