Blog

High-Performance CNC Stone Machine for Detailed Carving and Shaping

Precision and attention to detail are vital in stonework, whether it’s crafting memorials, creating sculptures, or designing architectural features. Advanced CNC stone machine has transformed the industry by offering unmatched accuracy and efficiency. These machines are a key asset for professionals looking to enhance their productivity and quality in stone carving. In this blog, we’ll explore the features and benefits of CNC stone machines, how they improve stonework, and why they are perfect for professional monument and stone carving businesses.

What is a CNC Stone Machine?

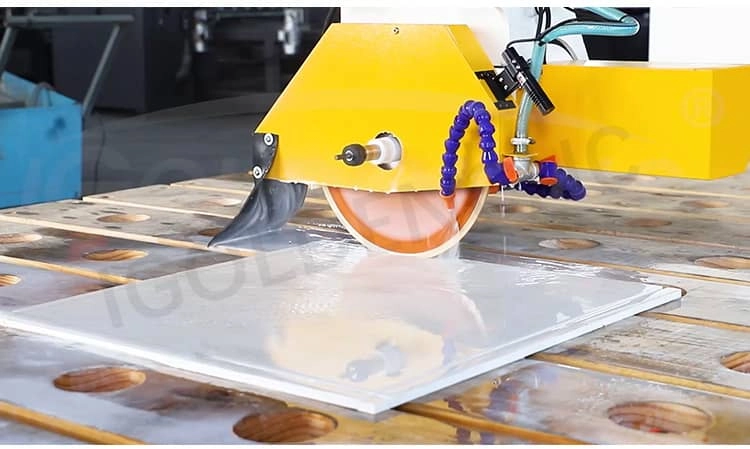

A CNC stone machine uses computer numerical control (CNC) technology to carve, engrave, and shape stone materials with high precision. Unlike traditional hand carving, CNC machines are guided by computer software that translates design files into instructions for the machine to follow. This automation ensures consistency, speed, and a level of detail that manual methods cannot achieve.

CNC stone machines are ideal for sculpting intricate designs, engraving text, and creating custom shapes. The versatility and accuracy they offer make them invaluable tools for the monument, stone carving, and architectural stone industries.

Why Choose CNC Stone Machines?

1. High Precision and Accuracy

One of the most significant advantages of CNC stone machines is their precision. When carving intricate designs, fine details, or complex patterns, precision is essential. These machines follow exact measurements and coordinates, ensuring the highest level of accuracy with every cut.

In the monument industry, this is especially important for engraving names, dates, and images on gravestones. A slight error in detail can impact the quality of the final product. With CNC technology, businesses can guarantee flawless results every time.

2. Efficiency and Speed

Traditional stone carving is time-consuming, with each project taking hours or days to complete. A CNC stone machine can carve the same design much faster. The process is automated, allowing the machine to work continuously without breaks. This speed significantly improves production times, which helps meet deadlines and increase output.

Moreover, CNC machines reduce the likelihood of human error, which can slow down the process and lead to costly mistakes.

3. Cost-Effective Production

While the initial investment in a CNC stone machine can be significant, the long-term savings are substantial. These machines reduce labor costs by automating many of the manual tasks involved in stone carving. This not only saves time but also decreases material waste by ensuring precise cuts every time.

The efficiency of a CNC machine enables businesses to take on more projects, increasing overall profitability. For companies that work on large-scale orders, like memorials or architectural stonework, CNC technology can dramatically increase production capacity.

4. Consistency Across Projects

Every stone carving, whether it’s a memorial, sculpture, or architectural element, must meet high standards of consistency. Manual carving can lead to slight variations between pieces. However, CNC machines ensure that every carving is identical, producing consistent results from one project to the next. This is particularly valuable when multiple pieces of the same design need to be produced.

Applications of CNC Stone Machines

1. Monument and Memorial Carving

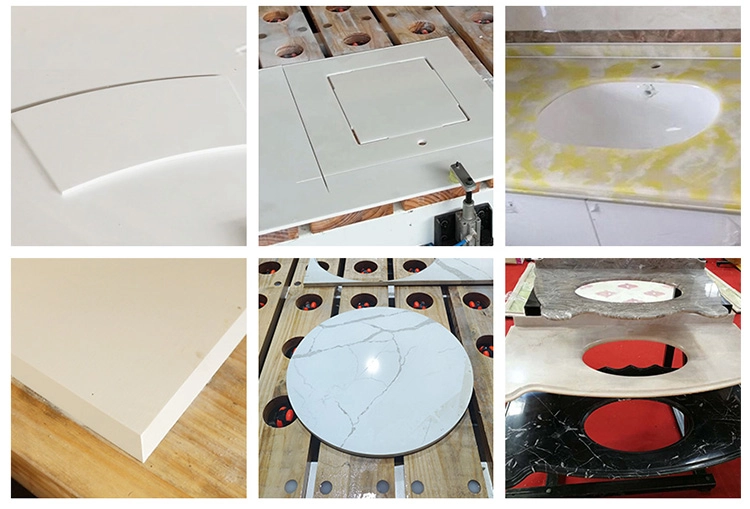

The monument industry relies heavily on CNC stone machines for engraving names, dates, logos, and images on gravestones and memorials. Custom memorials often require high levels of detail and precision, which is easily achieved with CNC technology.

CNC stone machines allow businesses to create highly detailed engravings quickly, reducing turnaround time while maintaining high quality. Clients can select from various fonts, images, and patterns to personalize their memorials.

2. Sculptures and Artistic Stonework

Artists and sculptors use CNC stone machines to create detailed stone sculptures and art pieces. The flexibility of CNC technology allows for the carving of intricate designs, whether it’s a lifelike portrait or a geometric sculpture. The machine’s ability to replicate precise details makes it an ideal tool for creating one-of-a-kind works of art.

CNC machines can carve from many types of stone, including marble, granite, and limestone. Artists can experiment with complex shapes and textures, as the machine’s precision ensures every detail is accurately replicated.

3. Architectural Stone Elements

In architectural stonework, CNC stone machines are used to create detailed components such as columns, arches, and facades. These machines allow stoneworkers to carve complex designs with accuracy and speed, ensuring that each piece fits perfectly into a building’s design.

For both exterior and interior stonework, CNC machines enable the creation of customized stone elements, from ornamental patterns to structural pieces.

4. Stone Furniture and Decorative Items

CNC stone machines are also used to carve decorative stone furniture, countertops, sinks, and tiles. These machines can cut, shape, and engrave stone with high precision, allowing for the creation of intricate designs on functional pieces. Custom-designed stone furniture is highly sought after for its aesthetic appeal and durability.

How to Choose the Right CNC Stone Machine

When selecting a CNC stone machine, there are several factors to consider to ensure that the machine meets your specific needs:

- Machine Size and Capacity: Choose a machine that suits the scale of your projects. Larger projects, like monuments and sculptures, require a machine with a bigger work area.

- Spindle Power: The spindle is the part of the machine that holds the carving tools. Higher spindle power is necessary for cutting through dense stones like granite.

- Software Compatibility: Look for a CNC machine that is compatible with popular design software like CAD or CAM. This ensures seamless integration between the design and production phases.

- Axis Count: A 5-axis CNC machine offers greater flexibility and precision. It allows for multi-dimensional carving, which is crucial for complex designs.

Maintenance and Support for CNC Stone Machines

To keep a CNC stone machine running at its best, regular maintenance is essential. Clean the machine thoroughly after each use to prevent stone dust from building up, which can affect performance. Lubricate the moving parts regularly to ensure smooth operation. Checking for wear and tear on the tools is also important to maintain cutting efficiency.

Many CNC stone machine manufacturers provide comprehensive support and training for operators, helping businesses maximize the lifespan of their equipment and get the most out of their investment.

Conclusion

CNC stone machines have revolutionized the stone carving and monument industries by providing tools that are faster, more precise, and more efficient than traditional hand-carving methods. Whether you’re engraving a simple inscription on a memorial or creating intricate sculptures, these machines ensure that every piece is crafted with the highest level of detail and consistency.

By investing in a CNC stone machine, businesses can enhance their productivity, improve their quality of work, and offer more custom stone carving options to clients. In an industry that values craftsmanship and precision, these advanced machines are essential for staying competitive and meeting client demands.

FAQ

1. How do CNC stone machines work?

CNC stone machines use computer-controlled software to guide carving tools through stone. The design is created in CAD software and then translated into precise movements by the machine.

2. Can CNC stone machines carve all types of stones?

Yes, CNC stone machines can work with a variety of stones, including granite, marble, limestone, and sandstone.

3. How long does it take to carve a stone piece with a CNC machine?

The carving time depends on the size and complexity of the project. Generally, CNC stone machines can complete projects much faster than traditional methods.

4. Are CNC stone machines difficult to operate?

Most CNC stone machines are designed to be user-friendly, with intuitive software and training resources available to operators.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.