Blog

CNC Stone Carving: Precision Engraving for Marble&Granite

In the world of stone artistry, CNC stone carving has transformed how intricate designs are created in hard materials like granite and marble. With the help of CNC (Computer Numerical Control) technology, stone carving has evolved from time-consuming manual labor to efficient, automated processes. This revolution has allowed artists, architects, and stone fabricators to achieve incredible precision and speed in their work.

This blog explores the benefits and capabilities of CNC stone carving, highlighting its significance in creating high-quality stonework, from memorials to architectural features.

What is CNC Stone Carving?

CNC stone carving uses advanced machines controlled by computer software to carve, engrave, or mill stone surfaces. The process begins by designing the pattern or image on CAD (Computer-Aided Design) software. Once the design is complete, the file is uploaded to the CNC machine, which follows the digital instructions to guide its tools in precise movements.

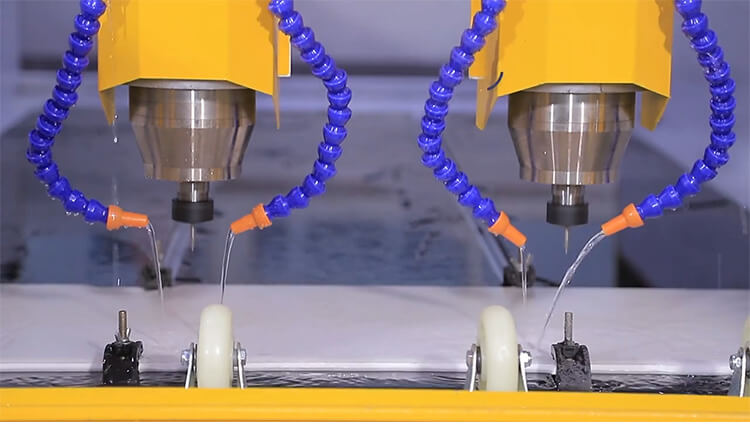

These machines are typically equipped with diamond-tipped tools to cut through tough stones like granite and marble, ensuring smooth, accurate results. With CNC technology, it is possible to create complex 3D designs, engravings, and shapes that were previously difficult or impossible to achieve by hand.

How Does CNC Stone Carving Work?

The workflow for CNC stone carving begins with a digital design created in CAD software. This design is then converted into machine instructions that control the movement of the carving tools. The CNC machine is capable of moving in multiple axes, which means it can approach the stone from several angles, creating intricate carvings in 3D.

One of the key advantages of CNC technology is the ability to use water cooling systems during the carving process. This helps keep the tools and stone cool, preventing overheating that can lead to cracks or damage.

Why Choose CNC Stone Carving?

1. Unmatched Precision and Consistency

The primary reason many industries turn to CNC stone carving is for its ability to deliver exceptional precision. The computer-controlled machines follow exact instructions, ensuring that every carving is consistent. In industries such as memorial design, even the smallest details—like dates, names, or intricate patterns—need to be reproduced accurately across multiple stones. CNC machines can perform this task flawlessly, ensuring each product matches the original design exactly.

2. Efficiency and Speed

Compared to traditional hand carving, CNC stone carving is significantly faster. Complex carvings that would take days to complete by hand can often be finished in just a few hours with the help of a CNC machine. The increased speed of production also reduces labor costs and increases output, allowing businesses to meet demand more easily.

For example, memorial stone businesses that need to engrave large numbers of headstones can complete each order much more quickly, without compromising on quality.

3. Versatility for Complex Designs

CNC stone carving is highly versatile, allowing for the creation of intricate and detailed designs. The machine’s ability to carve from multiple axes makes it suitable for creating 3D shapes, relief carvings, and even undercuts in stone. Whether you are designing a custom piece of art or producing decorative stonework for a building, CNC carving can handle a wide variety of tasks.

The versatility of CNC stone carving makes it ideal for different applications. From fine art sculptures to custom memorials, the possibilities are virtually endless.

4. Cost-Effective Production

Investing in a CNC stone carving machine can lead to significant cost savings in the long run. Although the initial cost of purchasing a machine can be high, the reduction in labor costs and the ability to produce items more quickly result in a faster return on investment. As CNC technology streamlines the carving process, businesses can focus their resources on other areas, such as marketing and customer service.

5. Customization for Personalization

Personalization is a key aspect of many industries, especially in memorial design. CNC stone carving offers unparalleled customization options, allowing businesses to create one-of-a-kind engravings. From personalized messages on gravestones to custom designs for commercial buildings, CNC machines can easily accommodate detailed and unique requests.

Whether you’re engraving a personal quote, logo, or artwork, CNC technology ensures that the final product perfectly matches the customer’s vision.

Applications of CNC Stone Cutting

1. Memorial and Monument Creation

In the memorial industry, CNC stone cutting has become indispensable. The need for precision and customization is crucial when creating gravestones and memorials. CNC machines can replicate intricate designs, text, and portraits with incredible accuracy, ensuring that each memorial is both beautiful and lasting.

With CNC stone cutting, stone fabricators can offer personalized, high-quality memorials at a faster pace, making it easier to meet customer demand without sacrificing quality.

2. Architectural Stonework

Architectural projects often require the carving of stone elements such as decorative facades, columns, and moldings. CNC stone cutting allows for precise cutting and shaping, ensuring that every piece fits perfectly. Whether you’re creating custom stone features for a new building or restoring a historic structure, CNC cutting provides a high level of detail and accuracy.

The ability to produce complex and large-scale stonework with CNC technology is especially valuable for architects and construction professionals seeking both creativity and efficiency in their projects.

3. Art and Sculpture

Artists are increasingly turning to CNC stone cutting to bring their creative visions to life. CNC machines offer the precision and versatility required to create detailed sculptures, ranging from abstract art to realistic representations.

Whether working with marble, granite, or other natural stones, CNC technology helps artists push the boundaries of what’s possible in stonework, offering an efficient way to achieve detailed, high-quality results.

Key Features to Look for in a CNC Stone Carving Machine

When purchasing a CNC stone carving machine, keep the following features in mind:

- High Power Spindle: The spindle should be strong enough to carve through hard stones like granite and marble.

- Multiple Axes: Look for machines that offer at least 3-5 axes of movement, as this allows for more intricate and detailed carvings.

- Durable Construction: A sturdy, vibration-resistant frame is essential for ensuring high-quality carvings.

- Water Cooling System: This helps to maintain tool and stone temperature, preventing damage during the carving process.

Conclusion

CNC stone carving technology has revolutionized how we create stonework. From precision memorials to intricate sculptures, this automated carving process offers speed, accuracy, and versatility. Whether you’re in the memorial industry or the art world, CNC machines can improve production quality and efficiency, allowing for greater creativity and customization.

If you’re considering integrating CNC stone carving into your business, investing in the right machine can lead to significant improvements in both output and profitability. With its ability to produce high-quality, personalized designs quickly and consistently, CNC technology is an invaluable tool for anyone working with stone.

FAQs

1. What types of stone can be carved using CNC machines?

CNC stone carving machines can carve a variety of stones, including granite, marble, limestone, and sandstone. The specific tools used depend on the stone’s hardness.

2. How does a CNC stone carving machine differ from traditional methods?

Traditional stone carving requires manual effort, often leading to inconsistent results. CNC stone carving uses computer-controlled machines that produce precise, repeatable designs at a much faster rate.

3. How long does it take to carve a memorial using a CNC machine?

The time required depends on the design’s complexity. A simple engraving might take a few hours, while more detailed work could take longer. However, CNC machines are significantly faster than manual methods.

4. Can I customize the designs I want carved into stone?

Yes, CNC stone carving offers excellent customization options. You can design anything from custom logos to detailed portraits, ensuring a highly personalized end product.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.