Blog

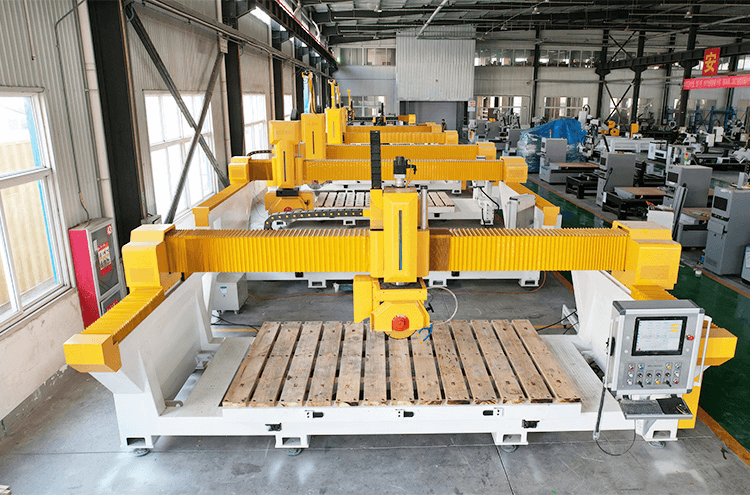

Granite CNC Machine for Sale

The demand for granite CNC machines has surged in recent years, driven by the need for precision and efficiency in stone cutting and engraving. Whether you’re in the construction, monument-making, or interior design industry, a granite CNC machine can dramatically enhance your ability to produce high-quality stone products, from countertops to custom sculptures. In this blog, we’ll dive into the features, benefits, and considerations you should keep in mind when searching for the best granite CNC machine for sale. By understanding the advantages of these machines, you can make a well-informed decision for your business.

What is a Granite CNC Machine?

The granite CNC machine is a specialized computer numerical control (CNC) machine designed to cut, carve, and engrave granite and other hard stones with extreme precision. These machines are equipped with high-powered spindles, durable cutting tools, and advanced software that allows them to handle the rigorous demands of stone fabrication. A granite CNC machine is ideal for tasks such as cutting granite slabs for countertops, engraving intricate designs on tombstones, or creating decorative stone pieces for landscaping or architecture.

The key difference between granite CNC machines and other types of CNC routers or milling machines is their ability to withstand the hardness and density of materials like granite, marble, and other natural stones. With high-torque spindles and diamond-coated tools, these machines ensure clean, precise cuts even through the toughest materials.

Key Features to Look for in a Granite CNC Machine

When shopping for a granite CNC machine for sale, there are several important features you should prioritize to ensure that you’re investing in a machine that meets your needs.

1. High-Powered Spindle

Granite is a dense and tough material, which requires a high-powered spindle to cut through effectively. Look for machines with spindles that have sufficient horsepower (HP) to tackle the hardest granite and marble types. Spindle power typically ranges from 5 HP to 15 HP, depending on the machine’s capabilities. A high-powered spindle will not only provide faster cutting speeds but also ensure a smoother finish and minimize tool wear.

2. Heavy-Duty Frame Construction

The frame of a granite CNC machine must be rigid and durable enough to support heavy materials. Look for machines with robust steel or cast iron frames that minimize vibrations during operation. This ensures both accuracy and longevity of the machine. A solid frame is especially important when working with large stone slabs, which can be heavy and difficult to manage without a stable base.

3. Multi-Axis Capabilities

While most CNC machines are designed with three-axis systems (X, Y, and Z), granite CNC machines often feature multi-axis capabilities, allowing for more intricate and complex cuts. Machines with 4, 5, or even 6 axes provide additional flexibility, enabling users to cut, shape, and engrave stone pieces from multiple angles in a single pass. This capability is particularly useful for creating detailed engravings or sculptural designs, which require the machine to work on all sides of the stone.

4. Water-Cooling System

Cutting granite generates a significant amount of heat, which can damage both the stone and the tools. To prevent this, many granite CNC machines come equipped with water-cooling systems. The cooling system not only reduces heat but also helps to clear away debris and dust generated during the cutting process. This feature improves the longevity of the machine and ensures cleaner, more accurate cuts. Additionally, the water helps reduce the risk of cracks or fractures in the stone during the cutting process.

5. Advanced Control Software

A granite CNC machine relies on sophisticated software to execute precise cuts and designs. Look for machines that come with easy-to-use and reliable CNC software, such as AlphaCam or ArtCAM. These programs enable you to design and program intricate shapes, engravings, and patterns that would be nearly impossible to achieve with traditional stone-cutting methods. Some machines even come with pre-loaded templates or custom design capabilities, allowing you to work with both 2D and 3D designs.

Benefits of Investing in a Granite CNC Machine

1. Increased Precision and Accuracy

One of the most significant advantages of using a granite CNC machine is its unparalleled precision. CNC technology allows for automated cutting based on computer-generated instructions, ensuring every cut is consistent and accurate. This is especially important when producing custom stone pieces, such as tombstones, countertops, or decorative items, where even small deviations from the design can lead to costly mistakes. The ability to reproduce designs with high accuracy is a significant benefit for businesses that rely on high-quality stone fabrication.

2. Faster Production Times

Traditional stone cutting and engraving methods are time-consuming and labor-intensive. Granite CNC machines automate much of the process, which significantly reduces production times. Complex designs that once took hours or days to produce can now be completed in a fraction of the time, allowing businesses to increase their output and meet tight deadlines. With faster turnaround times, you can also improve customer satisfaction and handle larger orders with ease.

3. Reduced Labor Costs

With a granite CNC machine, the need for manual labor is greatly reduced. Once the machine is programmed, it can operate autonomously, cutting and engraving stone with minimal human intervention. This not only saves on labor costs but also reduces the risk of human error. In industries like tombstone engraving or custom countertop production, labor costs can make up a significant portion of the overall expenses. By investing in a CNC machine, you can streamline your operations and reduce your reliance on manual labor.

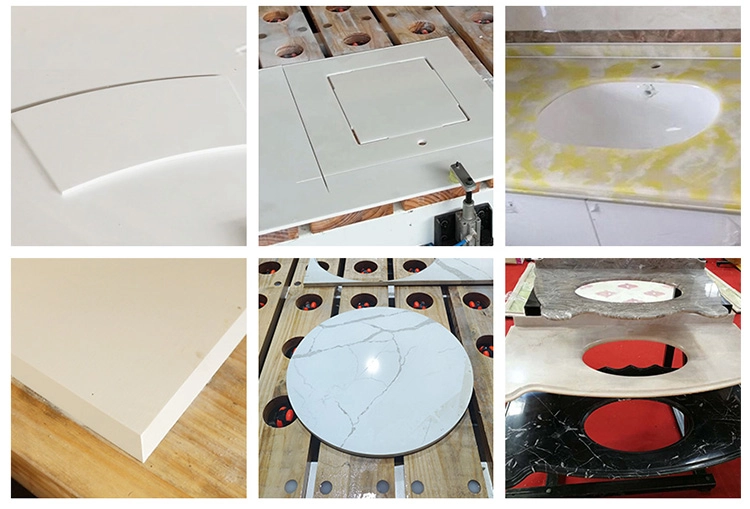

4. Greater Design Flexibility

Granite CNC machines provide an unmatched level of design flexibility, allowing users to create complex 2D and 3D designs with ease. From custom engravings to intricate patterns and even sculptures, the machine can handle a wide variety of creative projects. Many machines come with pre-configured templates and patterns, making it easy to get started. However, the real power of a CNC machine lies in its ability to execute highly detailed custom designs based on the operator’s specifications.

5. Consistency and Quality

Manual stone cutting and engraving methods are prone to variations and inconsistencies due to human error. Granite CNC machines, however, produce consistent and repeatable results, ensuring that each piece meets the same high standards of quality. This consistency is crucial in industries where precision is paramount, such as monument making, kitchen and bath countertops, and even the production of stone sculptures and artwork.

Applications of a Granite CNC Machine

The versatility of a granite CNC machine makes it suitable for a wide range of applications across various industries:

- Tombstone and Monument Engraving: Many granite CNC machines are used by monument makers and cemeteries to create detailed engravings on tombstones and memorials. The ability to carve custom inscriptions and intricate designs ensures that each memorial is unique and personal.

- Stone Countertops and Flooring: In the stone countertop industry, granite CNC machines are used to cut and shape granite slabs into countertops, backsplashes, and vanity tops. The precision of the machine ensures that the cuts are clean and accurate, reducing the need for manual adjustments.

- Architectural Stonework: Whether you’re working on custom stone features for homes or large-scale commercial projects, a granite CNC machine can create detailed architectural stone elements, including columns, pediments, and decorative accents.

- Custom Stone Art and Sculptures: Artists and sculptors also use granite CNC machines to bring their designs to life. These machines can carve intricate 3D sculptures, statues, and art pieces with remarkable detail and precision.

How to Choose the Best Granite CNC Machine for Sale

When searching for a granite CNC machine for sale, there are several factors to consider:

- Budget: Determine your budget and find a machine that fits within your price range. Prices can vary significantly depending on the machine’s size, features, and capabilities.

- Machine Specifications: Make sure the machine’s specifications match the type of work you plan to do. Consider factors like spindle power, axis configuration, and the size of the worktable.

- Brand Reputation: Choose a reputable brand with a track record of producing reliable and durable CNC machines. Companies like IGOLDENCNC, Haas, and Biesse are known for their high-quality CNC machines.

- Customer Support and Training: Ensure that the manufacturer offers excellent customer support and training. Proper training will help you maximize the machine’s potential and ensure smooth operations.

Conclusion

Investing in a granite CNC machine can significantly improve the precision, efficiency, and quality of your stone-cutting and engraving operations. With advanced features like high-powered spindles, multi-axis capabilities, and water-cooling systems, these machines are perfect for businesses in industries such as monument making, custom stone fabrication, and architectural design.

By choosing the right granite CNC machine for sale, you can enhance your production capacity, reduce labor costs, and deliver high-quality products that meet the growing demands of your customers. Whether you’re a small business or a large manufacturer, incorporating a CNC machine into your workflow will give you a competitive edge in the stone industry.

FAQs

1. What materials can a granite CNC machine cut?

A granite CNC machine can cut a wide range of materials, including granite, marble, quartz, ceramics, and other hard stones. Some machines are also capable of working with softer materials like wood, metal, and plastics.

2. How long does it take to set up a granite CNC machine?

The setup time depends on the complexity of the job and the size of the workpiece. However, once the machine

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.