Blog

5 Axis CNC Routing: Precision Cutting and Sculpting for Designs

In modern manufacturing, 5-axis CNC routing has revolutionized industries that require high precision and intricate designs. This includes sectors like aerospace, automotive, medical devices, and stone cutting. 5-axis CNC routers provide unmatched flexibility, enabling manufacturers to create complex parts and sculptures that were previously impossible with traditional methods. In this blog, we’ll explore the benefits of 5-axis CNC routing, how it works, and how to select the right 5-axis CNC router for your business.

What is 5-Axis CNC Routing?

5-axis CNC routing refers to a computer-controlled cutting process that uses five axes for tool movement. Traditional CNC machines operate along three axes: X, Y, and Z. These represent horizontal, vertical, and depth movements. A 5-axis CNC router adds two rotational axes (A and B), allowing the tool to tilt and rotate, accessing the material from all angles.

This added flexibility enables the machine to cut, carve, and shape parts in ways that are impossible with a 3-axis machine. The result is more complex and accurate cuts, which are essential for industries requiring high detail.

Advantages of 5-Axis CNC Routing

1. Increased Precision and Accuracy

The most significant benefit of 5-axis CNC routing is enhanced precision. The tool’s ability to cut from any angle results in highly accurate parts. This is crucial for industries such as aerospace, where tight tolerances are essential. For example, parts with complex geometries, such as turbine blades, can be made with minimal errors. This reduces the need for secondary finishing work.

2. Improved Efficiency

With 5-axis CNC routing, the tool can access all sides of a part in a single setup. This eliminates the need for multiple machine setups, saving time. Fewer tool changes and repositioning mean faster production. In industries with tight deadlines or high-volume production, 5-axis CNC routers significantly boost efficiency.

3. Ability to Work with Complex Geometries

One of the main advantages of 5-axis CNC routing is its ability to handle intricate and difficult geometries. Traditional machines struggle with parts that have curves, angles, or undercuts. But 5-axis CNC routers can handle these complex designs, making them invaluable for industries such as aerospace and automotive manufacturing.

4. Longer Tool Life and Reduced Wear

Since 5-axis CNC routers maintain continuous cutting, the forces on the tools are distributed more evenly. This helps reduce wear and extends tool life. In contrast, traditional CNC machines often experience uneven wear on the cutting tools, leading to more frequent replacements. 5-axis CNC routers provide a more cost-effective and efficient solution in the long run.

5. Higher Quality Surface Finishes

Another benefit of 5-axis CNC routing is the improved surface finish. The router’s continuous movement minimizes tool marks and imperfections. This means fewer post-processing steps are required, resulting in a cleaner and higher-quality final product. In industries that require fine finishes, like medical device manufacturing, this is a critical advantage.

How Does 5-Axis CNC Routers Work?

A 5-axis CNC router works by moving the cutting tool along five axes. Here’s how the axes are defined:

- X, Y, and Z Axes: These represent horizontal, vertical, and depth movements.

- A and B Axes: These rotational axes allow the tool or material to rotate. The A-axis rotates around the X-axis, while the B-axis rotates around the Y-axis. This added movement allows the router to cut at any angle, enabling highly precise and complex cuts.

By combining these movements, 5-axis CNC routers can create detailed parts in fewer setups. This reduces production time and increases accuracy.

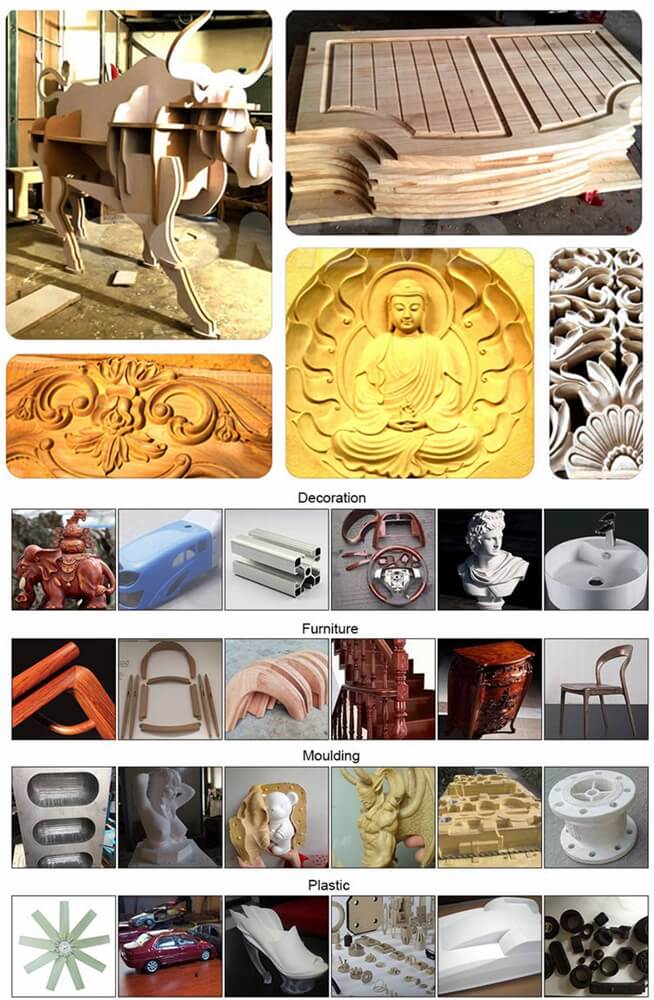

Applications of 5-Axis CNC Routing

1. Aerospace Manufacturing

In aerospace, precision is critical. 5-axis CNC routers are used to produce complex components, such as turbine blades, engine parts, and structural elements. The high precision provided by these machines ensures the parts meet strict tolerances required for safety and performance.

2. Medical Devices and Implants

The medical industry relies on 5-axis CNC routers for producing precise medical devices and implants. These machines can create custom prosthetics, surgical instruments, and implants with intricate designs. The ability to work with high precision is essential in ensuring the devices fit perfectly and function as intended.

3. Automotive Manufacturing

5-axis CNC routers are widely used in automotive manufacturing to produce parts such as engine components, custom body panels, and trim pieces. These routers can handle complex geometries, allowing automotive manufacturers to create lightweight yet durable parts that meet performance standards.

4. Stone and Sculpture Carving

Artists and fabricators use 5-axis CNC routers to carve intricate stone sculptures. Materials like marble, granite, and limestone can be shaped with high detail, which would be difficult to achieve using traditional carving methods. This technology helps produce stunning works of art with consistent precision.

5. Prototyping and Custom Manufacturing

5-axis CNC routers are also valuable in prototyping and custom manufacturing. Whether creating prototypes for new products or producing small batches of customized parts, these machines allow businesses to quickly and efficiently produce parts with complex designs.

Choosing the Right 5-Axis CNC Router

When selecting a 5-axis CNC router, consider the following factors:

- Work Area Size: Ensure the machine’s work area matches the size of your materials. A larger work area is essential if you work with big slabs of stone or large parts.

- Precision and Speed: Look for a router that offers both high precision and fast cutting speeds. Precision is critical for parts with tight tolerances, while speed is necessary for larger production runs.

- Compatibility with Software: Choose a machine that integrates with industry-standard design software like AutoCAD, SolidWorks, or Rhino. This will make it easier to turn your designs into machine-ready files.

- Tooling and Accessories: Check for the machine’s compatibility with different cutting tools, tool changers, and additional accessories. Some routers may support water cooling to improve cutting efficiency, especially when working with hard materials like stone.

- Customer Support and Training: Opt for a supplier that offers comprehensive training and customer support. Ongoing technical assistance can help you maintain your 5-axis CNC router and ensure it operates at peak performance.

Conclusion

5-axis CNC routing is transforming manufacturing by offering unparalleled precision, efficiency, and the ability to create complex designs. These routers are used in industries ranging from aerospace to sculpture, enabling businesses to produce intricate parts and designs with greater speed and accuracy.

If you are looking for a high-quality 5-axis CNC router, IGOLDENCNC offers top-of-the-line machines built to meet the demands of modern manufacturing. With flexible design options, high-speed capabilities, and precision cutting, IGOLDENCNC’s 5-axis CNC routers provide the tools necessary to enhance your business’s productivity and quality.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.