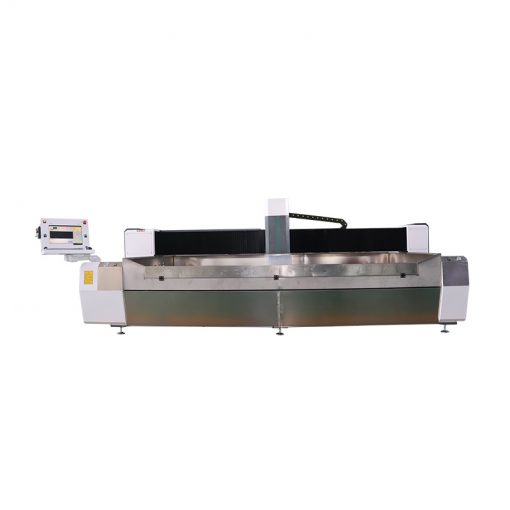

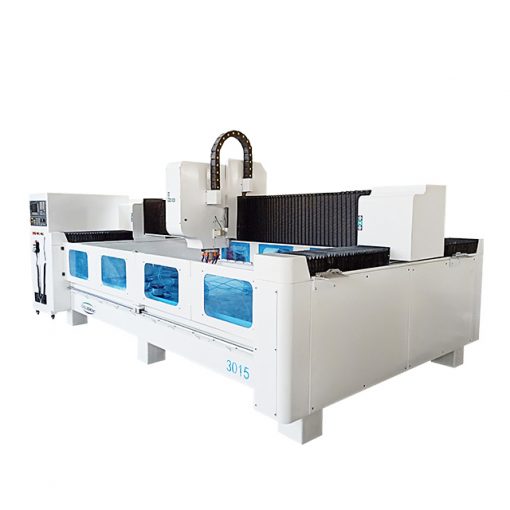

Glass milling machine

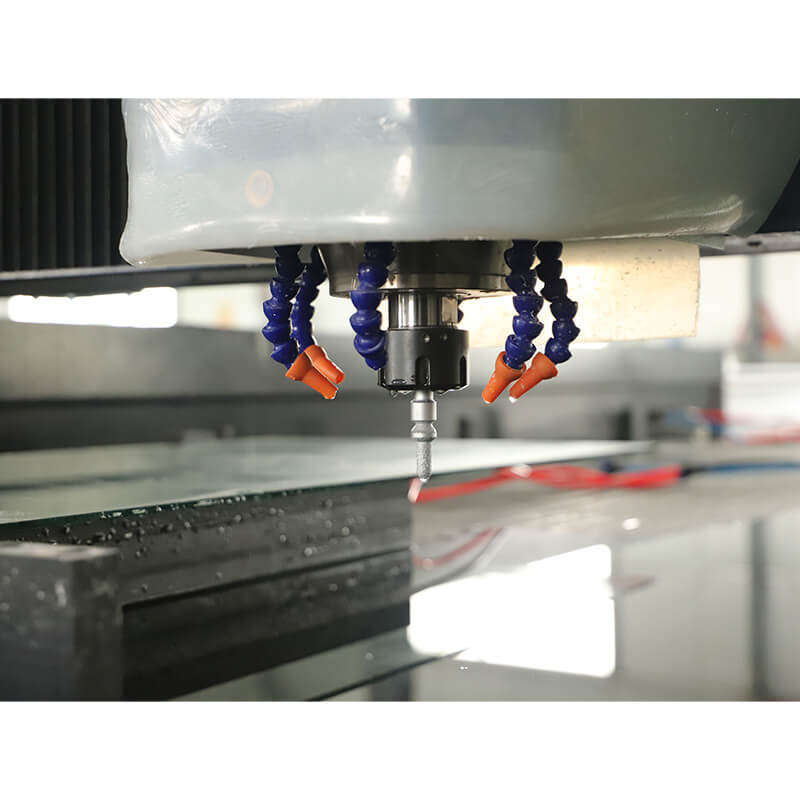

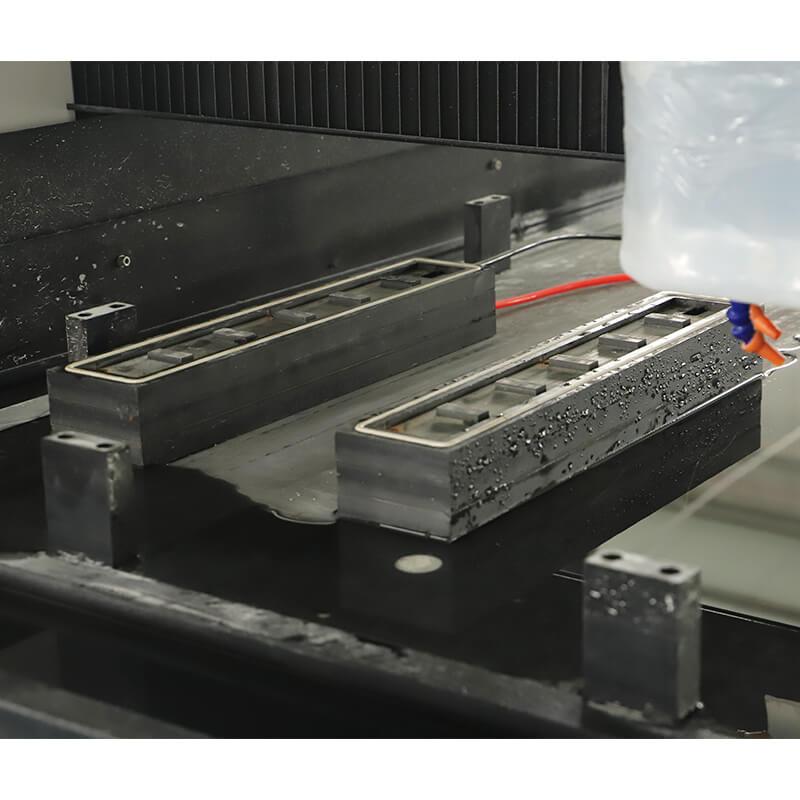

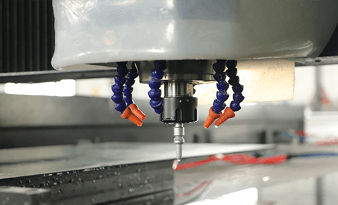

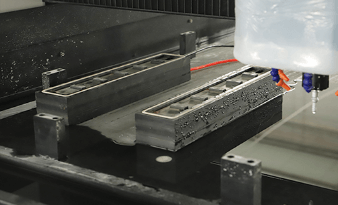

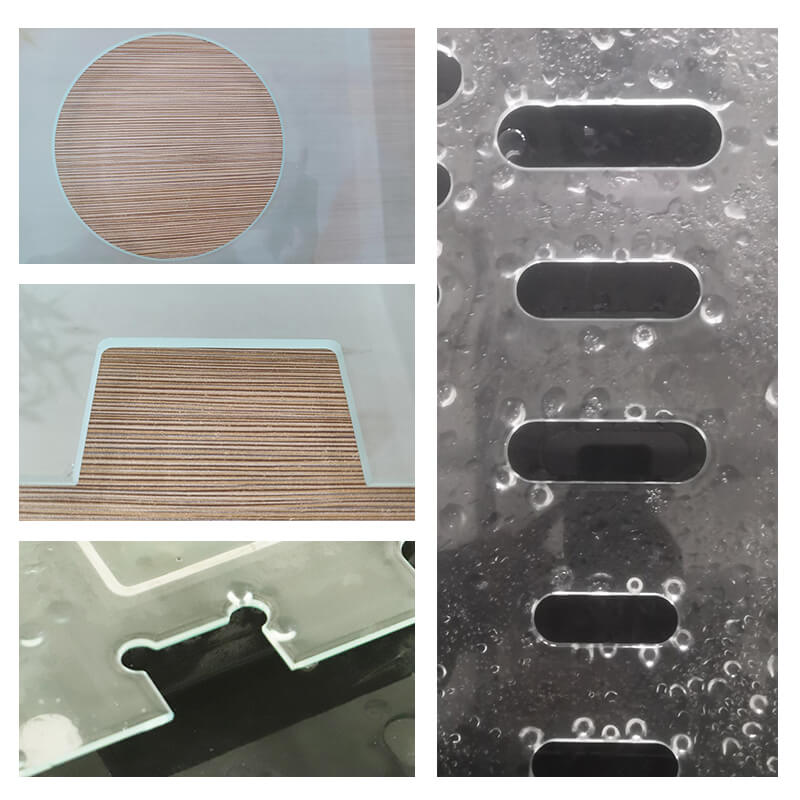

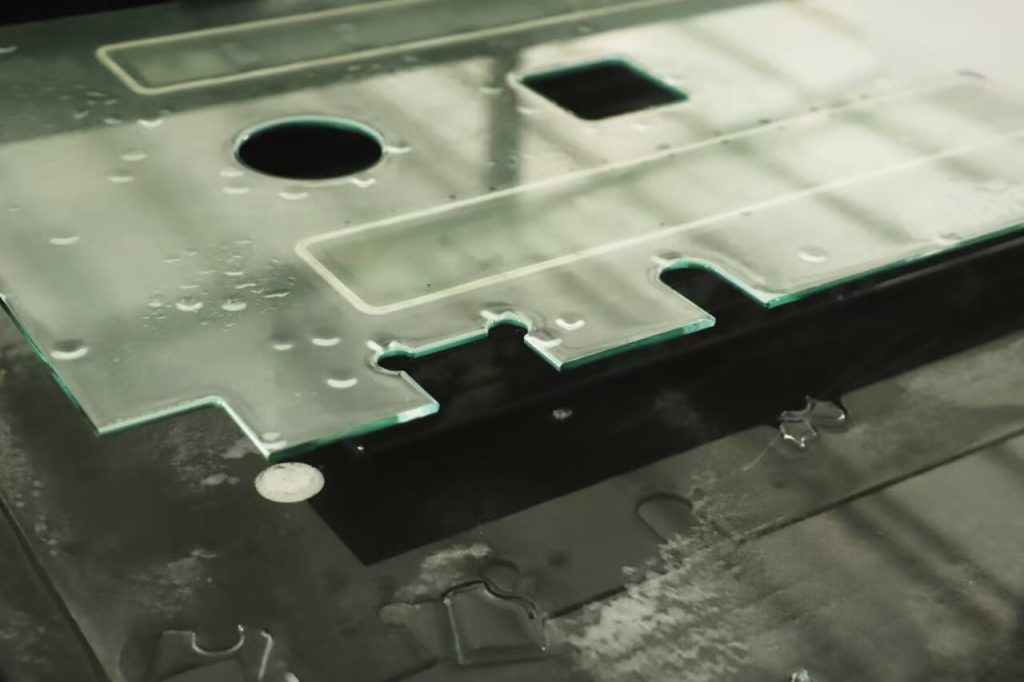

Glass Milling Machine is also called CNC Glass Machining Center is designed to deliver high precision and efficiency for cutting, engraving, drilling, and slotting glass materials. Whether for industrial manufacturing, custom designs, or artistic glassworks, this CNC machine provides reliable performance and excellent processing quality.

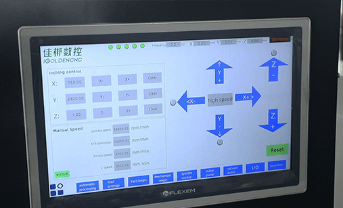

Glass Milling Machine is compact in design and precise in assembly. Adopt large inertia servo motor, industrial control system, constant power high-speed motorized spindle. Three (X/Y/Z) adopts high-precision rack transmission suitable for high-speed, low-speed and other cutting processing. lt has the characteristics of high machining precision and stable operation. Suitable for glass drilling, glass cutting, and glass edging and other processes.

Reviews

There are no reviews yet.