Blog

Best Stone CNC Router Center for Your Needs

If you’re searching for the best stone CNC router center, your quest ends here. These machines are essential for professionals in the stoneworking industry, offering unmatched precision, efficiency, and versatility. Whether you’re cutting, engraving, shaping, or polishing, a high-quality CNC router center ensures every project meets the highest standards.

This article will explore the features, parameters, applications, and benefits of stone CNC router centers. By the end, you’ll have a clear understanding of what makes a CNC router center exceptional and why IGOLDENCNC is your best choice.

Why Invest in a Stone CNC Router Center?

Stone CNC router centers are advanced tools designed to automate and simplify stone processing. Unlike manual methods, these machines allow professionals to achieve detailed designs and precise cuts consistently.

Key Advantages

- Precision: Achieve flawless results for intricate designs and engravings.

- Efficiency: Automate repetitive tasks, saving time and effort.

- Flexibility: Handle various functions, including cutting, polishing, and carving.

- Durability: Built to handle the demands of stone processing with ease.

- Cost Savings: Reduce material waste and labor costs significantly.

By automating labor-intensive tasks, a CNC router boosts productivity while ensuring high-quality results. Furthermore, it simplifies workflows for businesses of all sizes.

Features of the Best Stone CNC Router Center

To choose the best stone CNC router, it’s important to understand the features that set high-quality machines apart. Here are the key characteristics to look for:

1. Powerful Spindles

High-performance spindles are essential for processing hard materials like granite, marble, and quartz. With speeds of up to 24,000 rpm, these spindles ensure smooth and accurate operations. Moreover, they reduce the risk of material damage.

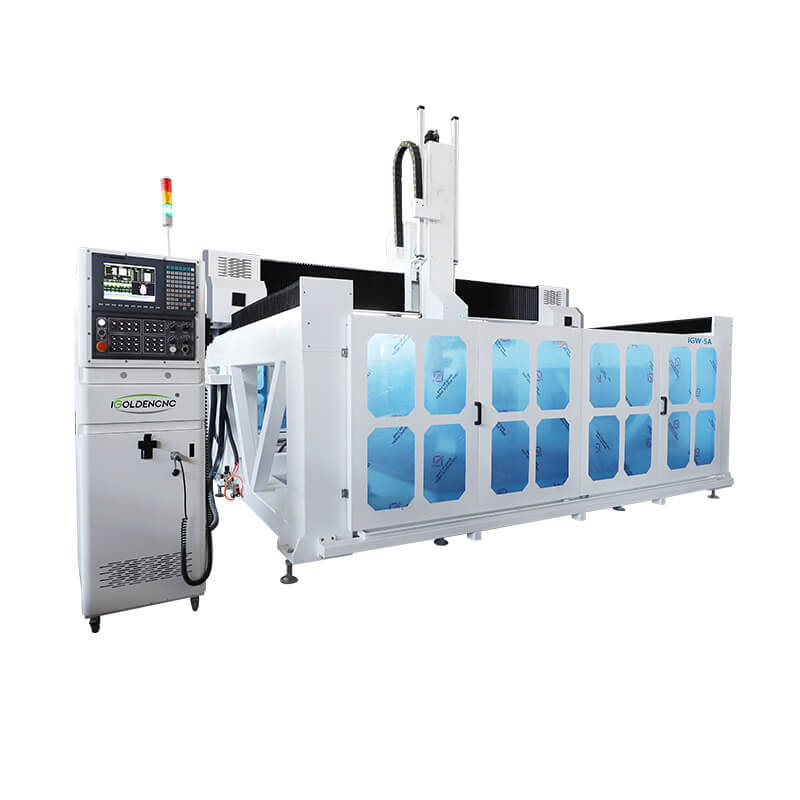

2. Sturdy Construction

A robust frame, often made of thickened steel, minimizes vibration during operation. This not only enhances precision but also extends the machine’s lifespan, reducing maintenance costs over time.

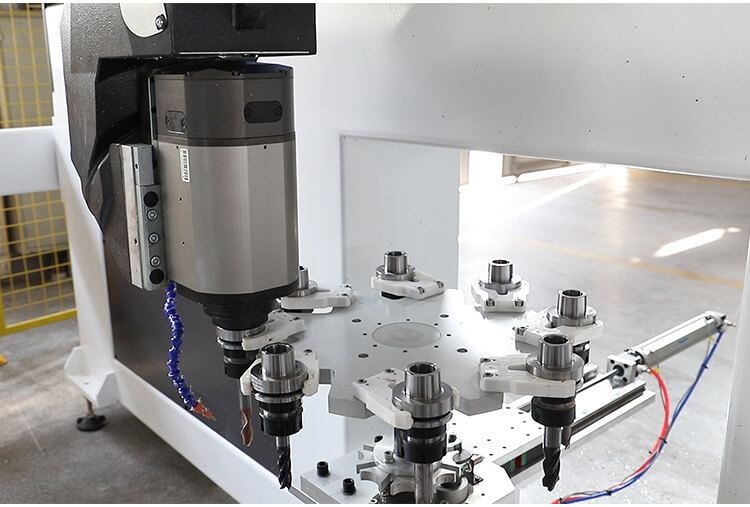

3. Automatic Tool Changer (ATC)

ATC systems allow the machine to switch between tools quickly, improving efficiency. For instance, a disc tool magazine with 6–10 slots enables seamless transitions between cutting, drilling, and polishing. Consequently, it saves valuable production time.

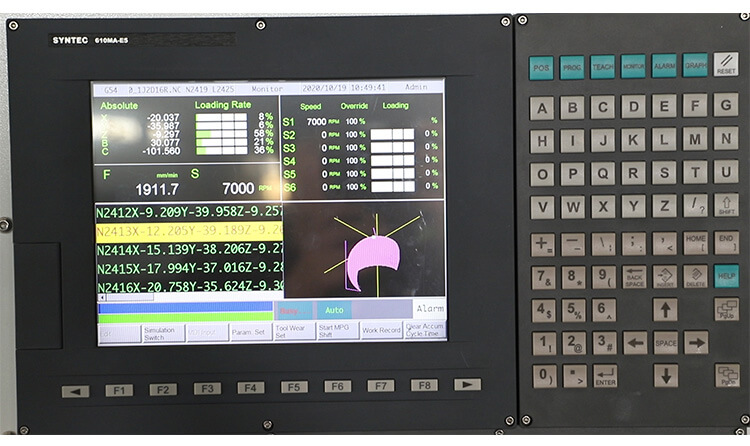

4. Advanced Control Systems

Modern CNC machines feature intelligent control systems like the Taiwan SYNTEC controller. These systems include functionalities such as:

- Breakpoint memory for resuming interrupted tasks.

- Power outage recovery to prevent wasted materials.

- Time prediction to estimate project completion.

These features ensure that even complex projects run smoothly and efficiently.

5. Customizable Specifications

Leading manufacturers offer customization options for working area size, spindle power, and voltage. This ensures the machine fits your specific production requirements, making it more versatile.

Parameters of a High-Quality Stone CNC Router

To help you make an informed decision, here’s a detailed table showcasing the parameters of a top-tier stone CNC router:

| Parameter | Specification |

|---|---|

| X, Y Axis Working Area | 1720 × 3040 mm |

| Z Axis Working Height | 600–1200 mm (optional) |

| Positioning Accuracy | ±0.03 mm |

| Re-Positioning Accuracy | ±0.02 mm |

| Max. Working Speed | 30,000 mm/min |

| Spindle Power | 14 kW (optional) |

| Spindle RPM | 24,000 rpm |

| Machine Weight | 2,300 kg |

| Voltage | 220V/380V ±10% 50–60Hz |

These specifications highlight the machine’s ability to handle complex tasks efficiently and accurately. Additionally, they ensure compatibility with various production needs.

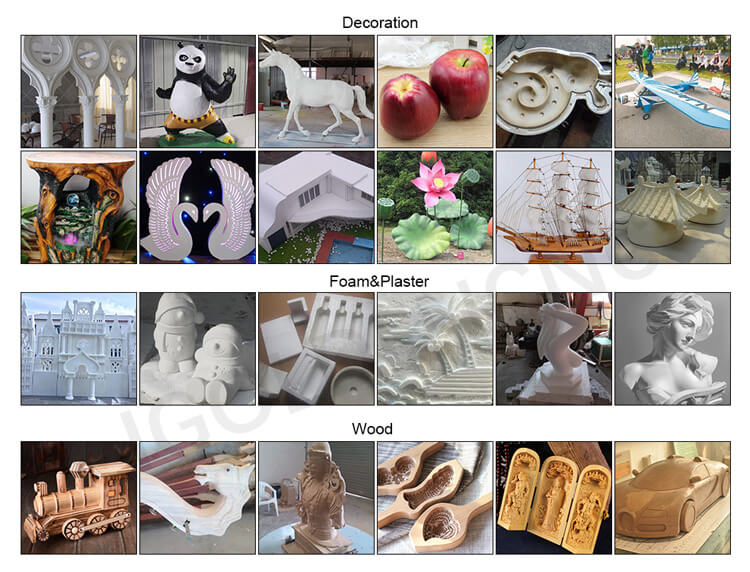

Applications of a best Stone CNC Router

The versatility of a stone CNC router makes it suitable for a wide range of industries. Below are some common applications:

1. Stone Processing

- Engraving intricate designs on headstones and monuments.

- Cutting and polishing kitchen countertops.

- Shaping decorative stone panels for walls and flooring.

2. Composite Materials Industry

- Trimming and punching fiberglass, plastic parts, and rubber products.

3. Mold Manufacturing

- Carving wooden molds for casting and resin products.

4. Furniture Industry

- Creating mortise and tenon joints for solid wood furniture.

- Shaping stair railings and decorative components.

5. Ceramic and Sanitary Industry

- Carving gypsum molds and other ceramic products with precision.

By offering such diverse functionality, a CNC router is an invaluable tool for businesses across multiple sectors. Moreover, it enables businesses to scale operations effectively.

How to Choose the Best Stone CNC Router

When selecting a CNC router, consider the following factors to ensure you’re getting the best value for your investment:

Build Quality:A strong and durable structure is essential for maintaining precision and withstanding long-term use. Furthermore, it reduces the need for frequent repairs.

Speed and Efficiency:Look for features like automatic tool changers and high-speed spindles to maximize productivity. Additionally, ensure the machine supports advanced software for seamless operations.

User-Friendly Interface:Choose a machine with an intuitive control system to simplify operation and reduce the learning curve. As a result, your team can start working with minimal training.

After-Sales Support:Ensure the manufacturer provides excellent support, including installation guidance, training, and technical assistance. This is particularly important for first-time buyers.

Welcome to IGOLDENCNC with the best stone cnc router center

At IGOLDENCNC, we pride ourselves on producing world-class CNC machines designed to meet the needs of modern businesses. Here’s what sets us apart:

Custom Solutions:We offer tailored configurations to meet your specific production needs, ensuring you get the perfect machine for your business.

Cutting-Edge Technology:Our machines incorporate advanced features like ATC, robust frames, and high-powered spindles for optimal performance.

Reliable Support:From initial setup to long-term maintenance, our team is dedicated to providing exceptional customer service.

Competitive Pricing:We offer top-tier machines at affordable prices, delivering excellent value without compromising quality.

Investing in the best stone CNC router center is a game-changer for your stoneworking projects. These machines not only deliver precision but also enhance efficiency and versatility, making them indispensable for professionals across various industries. Whether you’re shaping intricate designs or cutting large slabs, the right CNC router can redefine your workflow. At IGOLDENCNC, we understand the unique challenges of the stoneworking industry. That’s why we offer solutions tailored to meet your specific needs. When you choose us, you’re investing in a reliable partner committed to your success. Our machines are built to handle the most demanding tasks, ensuring every project is completed with unparalleled accuracy and efficiency.

Ready to take your stoneworking to the next level? Contact us today to learn more about our CNC router centers and discover how they can transform your operations. Let us help you find the perfect solution for your business needs!

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.