Blog

Best 5 Axis Stone CNC Machines for Professional Stonework

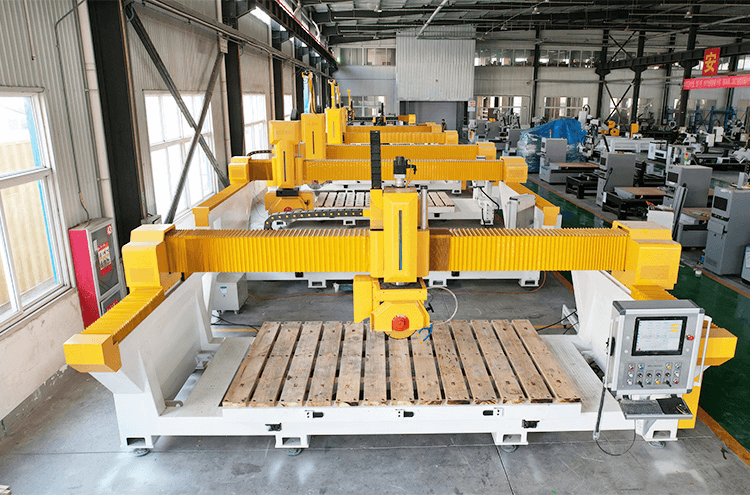

Whether you’re working with granite, marble, limestone, or quartz, the ability to create intricate designs and complex geometries is essential. This is where 5 axis CNC stone machines come into play. These advanced machines allow fabricators to cut, carve, and shape stone with unmatched precision, making them the ideal choice for professionals in the stone fabrication industry.

Unlike traditional 3-axis CNC machines, which move along three linear axes (X, Y, and Z), 5-axis CNC machines add two additional rotational axes, providing greater flexibility and the ability to machine complex shapes from multiple angles. This makes them particularly useful for producing architectural stone features, sculptures, countertops, and other high-precision stone components.

In this article, we will explore the best 5-axis stone CNC machines available on the market, their features, benefits, and applications. We will also provide guidance on selecting the right machine for your specific needs, ensuring that you can achieve professional-grade results in your stoneworking projects.

What is a 5-Axis Stone CNC Machine?

Have you ever wondered how a machine can change our lives? A 5-axis CNC machine is a computer-controlled device that automates the process of cutting, carving, and shaping stone materials. In addition to the standard three axes (X, Y, and Z), a 5-axis machine includes two additional rotational axes (A and B), allowing the machine to tilt and rotate the cutting tool or the workpiece. This enables the machine to access hard-to-reach areas and create complex geometries that would be impossible with a 3-axis machine.

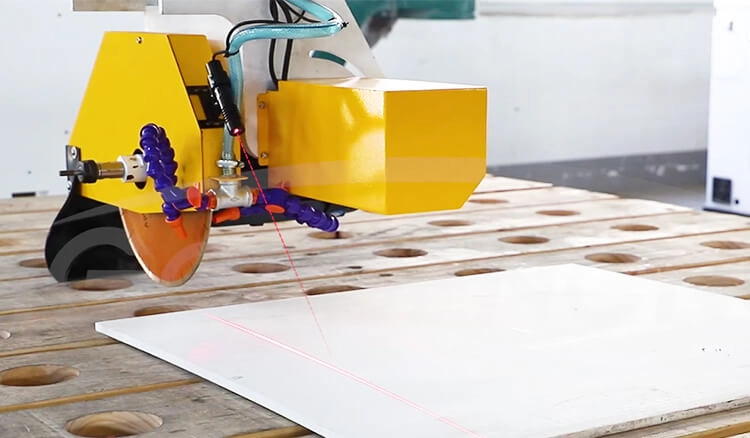

For stone fabrication, 5-axis CNC machines are equipped with diamond-coated tools and water cooling systems to handle the hardness and abrasiveness of natural stones like granite and marble. These machines are widely used in industries such as construction, architecture, memorial engraving, and artistic stonework.

How 5-Axis CNC Machines Work

The process of using a 5-axis CNC machine for stone involves several key steps:

- Design Creation: The first step is to create a digital design using CAD (Computer-Aided Design) software. This design contains all the necessary dimensions, patterns, and specifications for the stone component.

- CNC Programming: The CAD file is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program contains the instructions for the CNC machine, including tool paths, cutting speeds, and feed rates.

- Tool Setup: The CNC machine is set up with the appropriate cutting or engraving tools, typically diamond-tipped tools for stone. The machine is also equipped with a water cooling system to prevent overheating and reduce dust.

- Machining: The 5-axis CNC machine follows the programmed instructions to cut, carve, or shape the stone material. The machine moves along five axes (X, Y, Z, A, and B) to achieve the desired geometry and design.

- Finishing: After the machining process, the stone component may undergo additional finishing steps, such as polishing or edge profiling, to achieve the desired surface finish.

Benefits of Using a 5-Axis CNC Machine for Stonework

Using a 5-axis CNC machine for stone fabrication offers several advantages over traditional 3-axis machines and manual stoneworking methods. These benefits include:

1. Complex Geometries and Designs

The ability to move along five axes allows 5-axis CNC machines to create complex shapes, patterns, and designs that would be impossible with a 3-axis machine. This is particularly useful for applications that require intricate engravings, such as stone sculptures, custom countertops, or architectural elements.

2. Precision and Accuracy

5-axis CNC machines are capable of achieving extremely high levels of precision, often within micron-level tolerances. This is particularly important when working with stone, as even small inaccuracies can lead to costly errors or material waste.

3. Flexibility

With the ability to tilt and rotate the cutting tool or workpiece, 5-axis CNC machines offer greater flexibility in machining complex shapes from multiple angles. This makes them ideal for producing sculptures, columns, balustrades, and other intricate stone components.

4. Efficiency and Speed

5-axis CNC machines can complete complex machining tasks in a single setup, reducing the need for multiple setups and manual intervention. This increases production efficiency and allows for faster turnaround times, making it ideal for both prototyping and high-volume production.

5. Reduced Material Waste

By optimizing cutting paths and tool movements, 5-axis CNC machines minimize material waste, which is particularly important when working with expensive materials like granite and marble. Reducing waste can lead to significant cost savings, especially for large-scale projects.

FAQ: 5-Axis Stone CNC Machines

1. What materials can be machined with a 5-axis CNC machine?

5-axis CNC machines are capable of machining a wide range of stone materials, including granite, marble, limestone, quartz, and artificial stone. These machines are equipped with diamond-coated tools to handle the hardness and abrasiveness of natural stone.

2. What are the advantages of a 5-axis CNC machine over a 3-axis machine?

The main advantage of a 5-axis CNC machine is its ability to move along five axes, allowing for the creation of complex geometries and designs that would be impossible with a 3-axis machine. This makes 5-axis machines ideal for producing intricate stone components such as sculptures, columns, and architectural elements.

3. Can a 5-axis CNC machine be used for engraving stone?

Yes, 5-axis CNC machines are capable of engraving intricate designs and patterns in stone. The precision and flexibility of 5-axis machining allow for the creation of detailed engravings, such as memorials, monuments, and decorative stonework.

4. What industries use 5-axis CNC machines for stone fabrication?

5-axis CNC machines are used in a variety of industries, including construction, architecture, memorial engraving, and artistic stonework. These machines are ideal for producing high-precision stone components such as countertops, flooring, sculptures, and architectural features.

5. How do I choose the right 5-axis CNC machine for my business?

When selecting a 5-axis CNC machine, consider factors such as the size of the machine, spindle power, tooling options, software compatibility, and cooling system. It’s also important to choose a machine that meets the specific needs of your business, whether you’re producing large stone slabs or intricate sculptures.

The 5-axis CNC machine is a must-have for professional stone fabricators aiming for precision and efficiency. It excels in producing countertops, architectural elements, and sculptures. With its advanced capabilities, the machine ensures flexibility and accuracy for complex designs and intricate details.

Choosing the right machine is crucial for success. Use diamond-coated tools and follow best practices for stone machining to achieve outstanding results. This approach ensures components meet the highest standards of quality and performance.

For more details on 5-axis CNC machines and their applications, explore additional resources and guides on stone fabrication.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.