Blog

CNC Stone Cutting Machine: Precision Cutting for Granite&Marble

Cutting and shaping stone materials like granite and marble requires precision, efficiency, and reliability. Fortunately, CNC stone cutting machine have revolutionized the stoneworking industry. By automating processes and delivering high-precision solutions, they make it easier to cut, shape, and engrave a variety of stone types. Whether you’re crafting intricate designs or preparing large slabs for construction, these machines are indispensable for professionals.

In this blog, we’ll explore the features, benefits, and applications of CNC stone cutting machines, offering a comprehensive guide to help you make an informed decision.

What is a CNC Stone Cutting Machine?

A CNC stone cutting machine is a computer-controlled tool designed to cut, shape, and engrave materials like granite, marble, quartz, and sandstone. By leveraging Computer Numerical Control (CNC) technology, these machines execute operations with exceptional accuracy and consistency based on programmed instructions.

CNC machines combine advanced software, powerful spindles, and precision cutting tools. As a result, they handle everything from intricate designs to large-scale projects, making them essential in industries like construction, monument manufacturing, and custom stone design.

Key Features of CNC Stone Cutting Machines

- High-Precision Cutting Tools:CNC machines use diamond-tipped saw blades, routers, or water jet systems to create smooth, precise cuts. Consequently, they handle a wide range of materials, from soft limestone to hard granite.

- Multi-Axis Capabilities:Many machines feature multi-axis systems (e.g., 3-axis, 4-axis, or 5-axis). This allows them to move in multiple directions, enabling intricate carving and complex shapes.

- Durable Construction:Built with heavy-duty frames and corrosion-resistant materials, these machines withstand the rigors of daily stoneworking. In turn, this ensures long-lasting performance.

- Automatic Tool Changer (ATC):The ATC system enables seamless switching between tools for cutting, engraving, and polishing. This not only enhances productivity but also minimizes downtime.

- Water-Cooling Systems:Cutting stone generates significant heat. Thus, water-cooling systems maintain precision and extend the lifespan of tools by preventing overheating.

- User-Friendly Software:With intuitive CAD/CAM software, operators can easily program detailed designs. Moreover, even complex projects become manageable for users of all skill levels.

Benefits of CNC Stone CNC Machine

1. Unmatched Precision and Accuracy

CNC machines execute designs with micrometer-level precision. For instance, they are ideal for applications like custom countertops or intricate sculptures where exact dimensions are critical.

2. Increased Efficiency

Automation drastically reduces production time. Previously, tasks requiring hours of manual labor can now be completed within minutes, helping businesses meet tight deadlines.

3. Versatility Across Applications

From cutting and engraving to polishing and shaping, CNC machines adapt to various tasks. This versatility makes them indispensable in industries like interior design and monument manufacturing.

4. Reduced Material Waste

Optimized cutting paths minimize errors, conserving expensive materials like marble and granite. As a result, businesses can reduce costs significantly.

5. Lower Labor Costs

Automation reduces the need for skilled labor. Instead, operators can oversee multiple machines simultaneously, lowering overall labor expenses.

Applications of CNC Stone Cutting Machines

1. Granite&Marble Countertops

CNC machines cut and polish slabs with precision, ensuring accurate dimensions and smooth finishes for countertops. Additionally, they can handle custom edge profiles and sink cutouts.

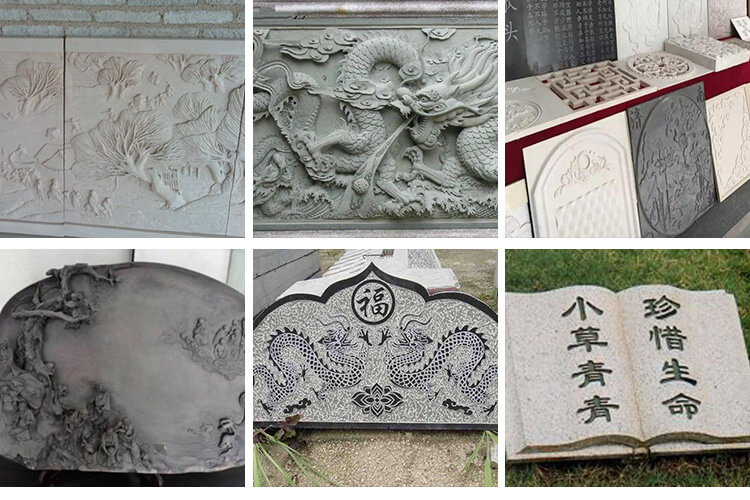

2. Monument and Memorial Engraving

Intricate designs and personalized engravings on tombstones and monuments are effortless with CNC machines. Furthermore, they ensure uniform results across batches.

3. Architectural Stonework

Custom stone elements like facades, columns, and decorative wall panels are crafted with CNC machines. As such, they are widely used in high-end architectural projects.

4. Tile Cutting and Shaping

CNC machines cut tiles into precise sizes and shapes, enabling custom patterns for floors, walls, and outdoor spaces. Moreover, they support artistic mosaic designs.

5. Custom Stone Art and Sculptures

Artists and designers use CNC machines for intricate sculptures and decorative pieces. Thanks to their precision, even the finest details are achievable.

Choosing the Right Stone CNC Router

When selecting a CNC stone cutting machine, consider these factors:

- Material Compatibility: Ensure the machine supports your stone types, such as granite or sandstone.

- Cutting Dimensions: Verify that the cutting area and thickness capacity align with your project needs.

- Power and Speed: Look for high spindle power and fast cutting speeds for efficient processing.

- Software Support: Choose a machine compatible with intuitive CAD/CAM software.

- Durability and Build Quality: Invest in robust machines designed for heavy-duty use.

Why Choose IGOLDENCNC for CNC Stone Cutting Machines?

At IGOLDENCNC, we specialize in manufacturing high-quality CNC machines tailored to the stoneworking industry. With years of expertise, we deliver advanced technology and robust designs that ensure precision and efficiency.

Key Advantages of IGOLDENCNC:

- Customizable Options: Multi-axis capabilities, ATC systems, and more tailored to your needs.

- Exceptional Support: From selection to training and maintenance, our team supports you every step of the way.

- Affordable Pricing: Competitive prices for premium machines, ensuring excellent value.

- Global Reputation: Trusted by professionals worldwide for reliable CNC solutions.

CNC stone cutting machines have transformed the stoneworking industry with their precision, efficiency, and versatility. Whether it’s cutting granite countertops, engraving marble monuments, or creating intricate sculptures, these machines empower professionals to deliver high-quality results effortlessly.Investing in a reliable CNC machine boosts productivity and reduces costs. At IGOLDENCNC, we offer expert guidance and top-tier machines to help you elevate your projects. Contact us today to learn how our solutions can enhance your stoneworking capabilities!

Pingback: 5 Axis CNC Stone Machines: Ideal for Intricate Designs&Shapes - iGoldencnc