Blog

Advanced Water Jet Cutting Machine for Clean and Precise Cuts

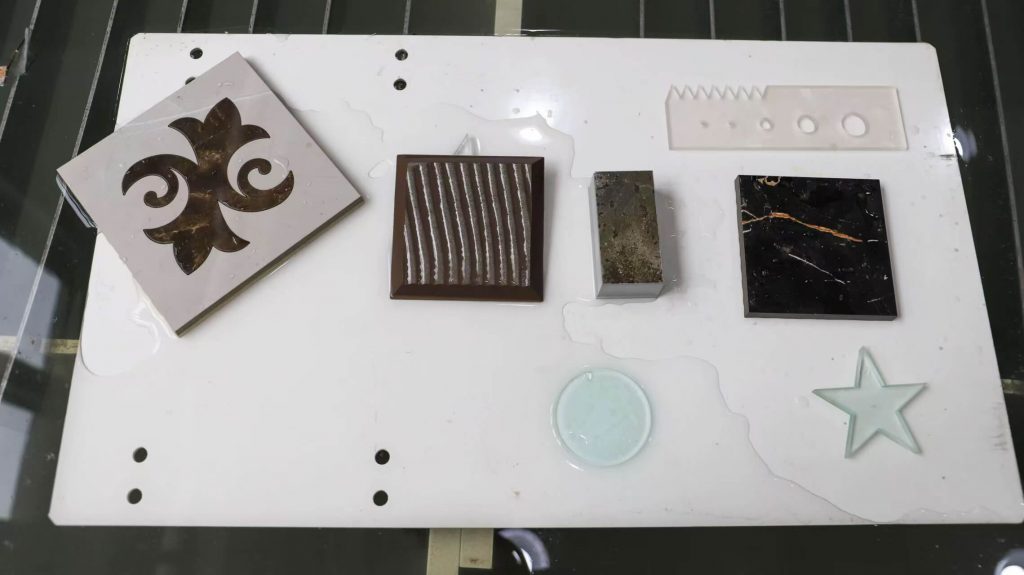

In the modern manufacturing and fabrication industries, precision and efficiency are key to producing high-quality products. One technology that has revolutionized cutting processes across a wide range of industries is the Water Jet Cutting Machine. This advanced cutting technology provides a cold cutting solution that offers unparalleled accuracy, versatility, and material preservation. Whether working with metal, glass, stone, or composite materials, the Water Jet Cutting Machine offers clean and precise cuts without compromising the integrity of the materials being processed.

What is a Water Jet Cutting Machine?

A Water Jet Cutting Machine uses a high-pressure stream of water, often mixed with an abrasive material like garnet, to cut through various materials. The power of the water jet comes from forcing water through a tiny nozzle at extremely high speeds—sometimes over 3,000 feet per second. This stream can cut through materials as thin as paper or as thick as several inches of metal, stone, or composite materials. One key benefit of water jet cutting is that it’s a cold cutting process. Since no heat is generated, there is no heat-affected zone (HAZ). This eliminates the risk of material deformation, property changes, or thermal distortion.

How Does a Water Jet Cutting Machine Work?

Water jet cutting machines operate by forcing water through a nozzle at extremely high pressures, typically ranging from 30,000 to 90,000 psi (pounds per square inch). Depending on the material, an abrasive substance like garnet may be added to the water stream. This helps cut through harder materials such as metals and ceramics.

A 5-axis CNC Water Jet Cutting Machine offers advanced capabilities with X, Y, Z, A, and C-axis linkage. The additional axes allow the machine to cut in multiple directions and angles, providing unmatched versatility for intricate designs and 3D shapes. These machines also feature a cutting head that ensures precise cuts, even at sharp angles or along continuous curves.

Key Features and Advantages of Water Jet Cutting

1.Precision and Accuracy

Water jet cutting machines, especially 5-axis CNC models, offer high precision. With cutting accuracies of up to ±0.1mm, the process ensures every cut is exact and consistent. This makes water jet cutting ideal for applications requiring tight tolerances and intricate designs.

2.Versatility and Multi-Functionality

Water jet cutting can handle a wide range of materials, from soft materials like foam and rubber to harder materials like metals, glass, ceramics, and stone. 5-axis water jet cutters enhance versatility by enabling cuts at any angle or in 3D space. This makes them perfect for complex shapes, bevel cuts, 3D modeling, and other advanced applications.

3.Cold Cutting Process

A major advantage of water jet cutting is that it’s a cold cutting process. Unlike laser or plasma cutting, it generates no heat. This prevents issues like heat distortion, material warping, or changes in chemical properties. Water jet cutting is ideal for heat-sensitive materials like certain plastics, composites, and metals.

4.No Material Deformation

Since water jet cutting is a non-contact process, it won’t deform or distort the material. The cutting head doesn’t touch the workpiece; only the high-pressure water stream applies force, ensuring delicate materials are handled carefully.

5.Environmentally Friendly

Water jet cutting is eco-friendly because it generates no fumes, toxic gases, or hazardous waste. The process also uses recyclable water, making it a sustainable option. In industries that prioritize sustainability, water jet cutting is an attractive solution.

Applications of Water Jet Cutting Machines

Water jet cutting machines serve a wide range of industries for various cutting applications, including:

- Aerospace: Aerospace companies use water jet cutting to cut complex parts from materials like titanium, aluminum, and composites.

- Automotive: The automotive industry relies on water jet cutting for precise fabrication of parts, especially prototypes and custom components.

- Architecture: Architects use water jet cutting machines to create intricate designs in stone, marble, and glass for features, facades, and decorations.

- Signage and Branding: The precision of water jet cutting makes it ideal for creating custom logos, signage, and lettering from various materials.

- Stone and Tile Cutting: The technology excels at cutting natural stones and tiles, providing smooth, burr-free cuts that traditional methods can’t achieve.

- Food Industry: Water jet cutters in the food industry slice through various products without causing contamination or heat-related damage.

With the ability to cut virtually any material, water jet cutting has become an essential tool in various industries that require high-quality, precision cuts.

Benefits of 5-Axis CNC Water Jet Cutting

The 5-axis CNC water jet cutting machine offers several significant improvements over traditional 3-axis systems. Here’s why you should consider upgrading to a 5-axis version:

- Complex Geometry Handling A 5-axis CNC water jet cutting machine can rotate the cutting head along multiple axes, allowing for more complex geometries. This makes it perfect for cutting intricate curves, bevels, and other advanced shapes that cannot be achieved with a traditional 3-axis machine.

- Efficient Cutting at Any Angle With the ability to rotate the cutting head to any angle, a 5-axis water jet cutter can achieve cuts at sharp angles, including cylindrical, conical, and spiral cuts. This capability is especially important in industries that require high-precision 3D cuts.

- Reduced Material Waste Due to the precision and versatility of 5-axis cutting, there is less material waste during the cutting process. This reduces material costs and contributes to more sustainable manufacturing practices.

- High-Speed Cutting Modern 5-axis water jet cutting machines can achieve cutting speeds of up to 20 meters per minute, significantly improving productivity and reducing turnaround times for complex cutting jobs.

- Cleaner Cuts with Smooth Surfaces The cutting process produces clean, smooth edges without the need for post-processing. Unlike other cutting methods, such as plasma or laser cutting, water jet cutting leaves no burrs or slag, resulting in a higher-quality finished product.

Product Specifications of a 5-Axis CNC Water Jet Cutter

Here is an overview of the technical parameters of a high-performance 5-axis CNC water jet cutting machine:

| Technical Parameter | Value |

|---|---|

| Model | iGWJ-4020 |

| Platform Size | 4200 * 2200mm |

| Cutting Stroke | 4000 * 2000 * 150mm |

| A Axis Rotation Angle | ±60° |

| C Axis Rotation Angle | Infinite rotation |

| Max Cutting Speed | 20 m/min |

| Max Running Speed | 50 m/min |

| Cutting Accuracy | ±0.1mm |

| Rotating Accuracy | ±0.1° |

| Control Accuracy | ±0.05mm |

| Repeated Positioning | ±0.05mm |

| Control System | WEIHONG |

| Motor Servo | Japan Yaskawa Servo Motor |

| Guide Rail | Taiwan HIWIN |

| Platform | Steel Platform |

The Water Jet Cutting Machine is an advanced cutting solution that combines precision, versatility, and efficiency. With capabilities such as 5-axis cutting, it has become an invaluable tool in industries ranging from aerospace and automotive to architecture and manufacturing. By providing cold cutting without heat distortion, it ensures that the integrity of materials is maintained throughout the process. With its ability to cut virtually any material and produce high-quality, smooth cuts, the Water Jet Cutting Machine is an essential investment for businesses looking to stay ahead in a competitive market.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.