Blog

CNC Granite Machines for Professional Stone Carving and Cutting

CNC granite machines have transformed the stone fabrication industry by offering exceptional precision, speed, and flexibility. These machines use advanced computer numerical control (CNC) technology, automating the cutting and shaping of stone materials like granite, marble, and quartz, allowing for the creation of complex designs and ensuring high levels of accuracy.

Varieties of CNC Stone (Granite & Marble) Cutting Machines

CNC Bridge Saw

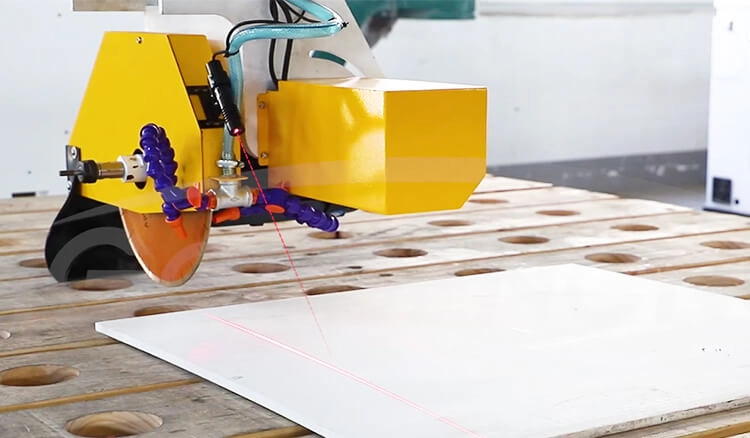

CNC bridge saws are widely used for cutting large stone slabs such as granite, marble, and quartz. Featuring a bridge structure that supports the cutting head, these machines ensure precise and controlled cuts.

A CNC bridge saw utilizes a bridge-like design, where the cutting head is guided by a computer program to perform accurate cuts on various stone types. The machine typically uses a diamond blade that can slice through materials like granite and marble, with high precision and speed. The automation of CNC technology improves efficiency, making it an essential tool for both small and large-scale projects.

The intelligent five-axis CNC bridge cutting machine is a high-tech device with multiple functions, including photo-taking, plate positioning, automatic measurement, and multi-directional cutting. It can cut large plates, create circular or angular cuts, and perform a wide variety of functions like chamfering, drilling, and hole cutting.

Key Advantages of CNC Bridge Saws:

- High cutting precision

- Capable of processing large slabs

- Automated cutting process

- Durable and robust for long-term use

Common Applications:

- Countertops

- Flooring

- Wall cladding

- Architectural elements

5-Axis Bridge Cutting Saw Specifications

| Technical Indicator | Parameter |

|---|---|

| Model | iGS-B3320 (Pro) |

| X-Axis Stroke | 3300mm |

| Y-Axis Stroke | 2000mm |

| Z-Axis Stroke | 255mm (Blade Diameter 400mm) |

| A-Axis | 90° |

| C-Axis | 360° |

| Saw Blade Motor Power | 7.5kW / 11kW / 15kW / 18.5kW |

| Blade Diameter | 350mm / 400mm / 450mm |

| Motor Power (XYZ Axis) | 1.8kW (Z-Axis Holding Brake) |

| Input Power | 3-phase AC 380V / 220V 50-60Hz |

Standard Features:

- Laser positioning

- Table flipping for different cutting angles

- Automatic mitering, chamfering, and hole drilling

Optional Features:

- Suction cup displacement for better stone positioning

- Automatic photo layout for precise cutting

- Software for enhanced measurements

CNC Water Jet Cutters

CNC water jet cutting machines use high-pressure water mixed with abrasives to cut through granite and other types of stone. This cutting method avoids heat generation, preventing material deformation and ensuring high-quality cuts.The CNC water jet system consists of a pressurization unit, a cutting platform, a sand storage system, and a control system. It ensures clean, precise cuts on a variety of materials, including difficult-to-cut materials like titanium alloys and composites.

Key Advantages:

- Zero heat generation, avoiding material distortion

- Ideal for detailed and intricate designs

- Capable of cutting multiple materials

- Versatile for both soft and hard materials

Common Applications:

- Decorative stonework

- Inlays and custom shapes

- Artistic stone designs

Water Jet Cutter Specifications:

| Technical Indicator | Parameter |

|---|---|

| Model | iGWJ-4020 |

| Platform Size | 4200*2200mm |

| Cutting Stroke | 40002000150mm |

| Max. Cutting Speed | 20m/min |

| Max. Running Speed | 50m/min |

| Cutting Accuracy | ±0.1mm |

| Platform | Steel |

| Motor | Japan Yaskawa Servo Motor |

| Control System | WEIHONG |

| Electrical Components | Schneider |

The water jet cutting method is well-suited for applications requiring high precision, especially when working with thick materials or designs that require minimal cutting waste.

Stone CNC Router

Stone CNC routers are highly versatile machines capable of cutting, shaping, and engraving granite, marble, and other stones. These machines feature rotating tools, which can perform a wide range of operations from simple cuts to intricate engravings.

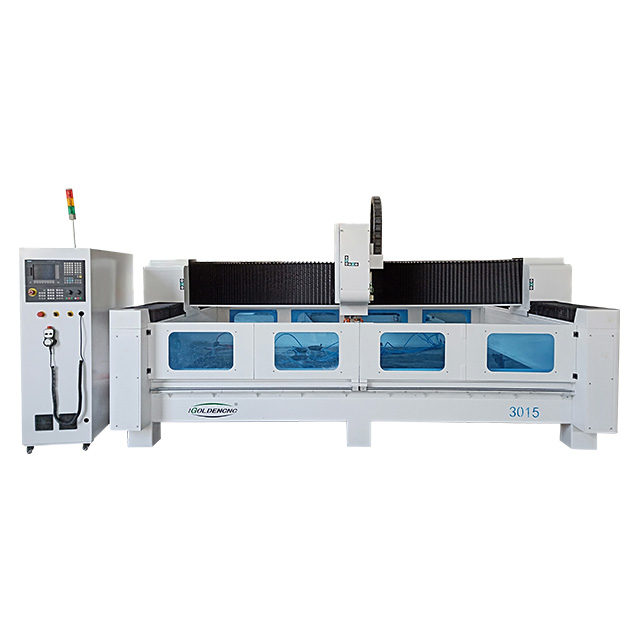

ATC Stone CNC Machining Center

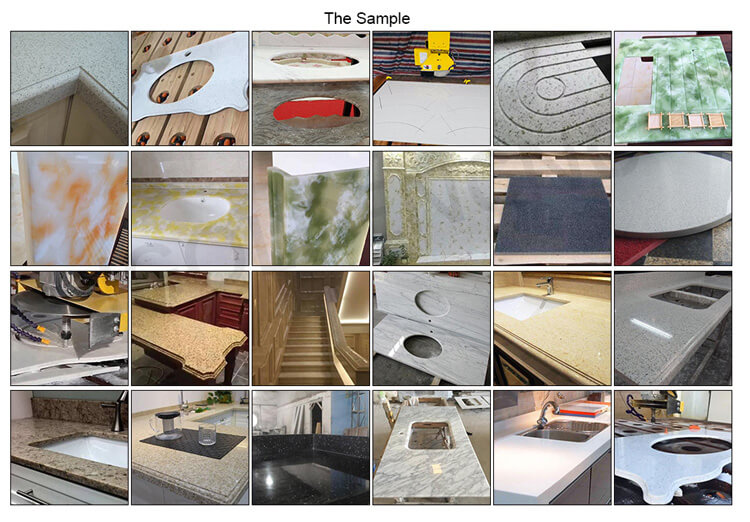

Stone processing center is a CNC automatic engraving high-tech equipment, mainly used for the processing of stone countertop, can achieve a feeding to complete all the processes of countertop processing. Stone countertop copying, special-shaped processing, grinding Roman edge, treatment of circular arc after retaining water, cutting basin holes, grinding basin along, polishing and other processes can also do stone relief carving.

Widely used in kitchen countertops, bathroom countertops, stone tabletop, coffee table countertop, TV counter surface processing, can also be used in billiard table, welcome table countertop, ordering table and other stone countertops.

Technical Specifications for Quartz Stone CNC Processing Center

| Technical Data | Parameter |

|---|---|

| X, Y Axis Working Area | 2000*3000mm |

| Z Axis Working Height | 500mm |

| Positioning Accuracy | 0.05mm |

| Max. Running Speed | 20000mm/min |

| Spindle RPM | 24000 RPM |

| Working Voltage | AC 380V±10% / 50-60Hz |

| Machine Weight | 3300kg |

The ATC (Automatic Tool Change) system allows for seamless, automated changes between tools, making it easier to handle complex tasks. This includes countertop shaping, edge grinding, hole cutting, and more.

Benefits of CNC Granite Stone Cutting Machines

- Precision and Quality

CNC granite cutting machines provide unmatched accuracy, enabling the production of intricate designs and high-quality finishes. The automated system ensures that each cut is precise with minimal waste. - Speed and Efficiency

These machines increase production speeds and reduce human error, which is essential for high-volume operations. Automation significantly cuts down on labor time and costs, improving overall efficiency. - Versatility

CNC granite machines are adaptable to various types of stone, including granite, marble, and engineered stone. Their ability to handle a range of materials makes them suitable for diverse applications. - Durability

CNC granite machines are designed with durability in mind, equipped with robust components that can endure the demanding nature of stone cutting. This reliability ensures long-term investment value. - Reduced Labor Costs

Automation reduces the need for manual labor, ensuring a more streamlined production process. Complex designs and shapes can be created with ease, minimizing the risk of human error.

CNC Stone Cutting FAQ

1.What stones can be cut using CNC granite machines?

CNC granite machines can process various stone types such as granite, marble, quartz, and engineered stones.

2.How does CNC cutting compare to traditional cutting methods?

CNC cutting offers higher precision and faster processing speeds compared to manual cutting. The automation ensures more intricate designs and consistent results.

3.Which industries benefit from CNC stone cutting machines?

Industries such as architecture, stone countertop fabrication, decorative stonework, flooring, and wall cladding benefit from the speed, accuracy, and versatility of CNC machines.

4.Are there any limitations to CNC granite cutting machines?

While CNC granite cutting machines are highly effective, factors such as material thickness, cutting speed, and stone type should be considered when choosing the right cutting method.

5.What maintenance is required for CNC granite cutting machines?

Regular maintenance is essential, including cleaning, inspecting tools, ensuring proper alignment, and monitoring overall machine performance to maximize longevity and functionality.

CNC granite stone cutting machines are an invaluable tool in the stone fabrication industry. Offering precision, efficiency, and versatility, these machines are capable of cutting, shaping, and engraving a wide variety of stones, including granite, marble, and quartz. Whether you’re working on countertops, custom stone shapes, or decorative elements, investing in a CNC granite cutting machine can significantly enhance both the quality and productivity of your projects.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.