Blog

Affordable Homemade 5 Axis CNC Router: Precision CNC Machine

Creating a 5-axis CNC router at home is an exciting, cost-effective way to access advanced machining capabilities. While traditionally expensive, the option to build a homemade 5-axis CNC router is now a reality for hobbyists and small business owners alike. This machine’s ability to cut in multiple directions enables complex cuts, smooth curves, and intricate 3D designs that bring your projects to a professional level. In this guide, we’ll explore how to build an affordable 5-axis CNC router and introduce IGOLDENCNC’s high-quality 5-axis CNC routers as a valuable alternative.

Why Build a Homemade 5-Axis CNC Router?

Building a homemade 5-axis CNC router offers several distinct advantages. For individuals who enjoy a challenge, it’s an educational and hands-on way to delve into CNC technology, electronics, and machining. By building the router yourself, you can customize the machine’s size, capabilities, and budget to suit your specific needs. Here’s why a homemade 5-axis CNC router can be a great choice:

- Cost Savings: Factory-made 5-axis CNC machines are typically quite expensive. Building a homemade model can significantly reduce costs by allowing you to source parts individually, often for much less.

- Customizability: When you build your own CNC router, you can tailor its specifications to match the scale and materials of your projects, ensuring the machine’s functionality meets your needs.

- Expanded Design Capabilities: A 5-axis CNC router’s advanced movement allows for precise 3D shapes, contours, and complex cuts that would be challenging to achieve with a simpler machine.

While a homemade machine provides a range of benefits, IGOLDENCNC’s professional 5-axis CNC routers remain an excellent alternative if you seek immediate high performance, reliability, and enhanced capabilities.

Components for Building a Homemade 5-Axis CNC Router

Building your own 5-axis CNC router requires selecting quality components that work together to achieve precision cutting. Here’s an overview of the essential parts:

Sturdy Frame and Gantry:A solid frame is crucial to minimize vibrations during operation, ensuring high precision. Aluminum or steel are durable options for DIY frames.The gantry needs stability for smooth movement across all axes.

High-Quality Stepper Motors:Stepper motors control the movement of the router along each axis. For a 5-axis setup, you’ll need motors with high torque to handle intricate movements, along with compatible motor drivers.

Spindle:The spindle is the cutting tool itself. Select one based on your primary material, whether that’s wood, metal, or plastic. It’s essential to choose a spindle with enough power to handle heavy-duty tasks if needed.

Controller Board:The controller board processes instructions and sends signals to the motors, enabling precise multi-axis control. Boards like Arduino with GRBL firmware or more advanced options compatible with 5-axis functions are suitable for DIY setups.

Rotational Axes Components:The rotational components for the additional axes allow the spindle to tilt and rotate, enabling intricate 3D cuts. Rotary tables or pivoting mechanisms are typically used here.

Linear Rails and Ball Screws:For smooth and accurate motion, linear rails guide the movement of the router, while ball screws help translate motor rotations into precise linear motion, critical for high-detail projects.

Homemade a 5-Axis CNC Router: Step-by-Step Tips

Define Your Budget and Requirements

- List your desired features and determine the primary materials you’ll be working with. This will help you select components that match your specific project goals.

Select Compatible Parts

- Choose parts that are compatible with each other, especially the motor and driver combinations, and the controller board’s compatibility with the 5-axis requirements. Many users find it helpful to purchase a kit containing basic components to simplify the process.

Focus on Precision During Assembly

- Accuracy in assembly is crucial, as even minor alignment errors can affect the performance of a 5-axis router. Measure, align, and secure components with care, and consider using a level or calibration tools to maintain accuracy.

Test and Calibrate

- Once assembled, test your router on a variety of materials. Fine-tune the settings and make necessary adjustments to the software to ensure each axis performs precisely.

IGOLDENCNC’s Professional 5-Axis CNC Routers: A Convenient Alternative

While building a homemade CNC machine can be rewarding, it does come with challenges and a learning curve. If you’re looking for a more efficient path to high-precision cutting, IGOLDENCNC’s line of 5-axis CNC routers offers a top-tier alternative for both small businesses and serious hobbyists. Here are some highlights:

Why Choose IGOLDENCNC?

Reliable Precision: IGOLDENCNC’s 5-axis CNC routers offer professional-grade precision out of the box, capable of producing complex and detailed parts without the need for constant calibration.

Versatile Functionality: These machines can handle a wide range of materials, including metals, plastics, wood, and stone, making them suitable for diverse applications.

User-Friendly Interface: The machines come with advanced CNC software that supports complex 5-axis operations, streamlining the design-to-production process.

Durability and Stability: Built with high-quality materials, IGOLDENCNC routers are designed for heavy use, providing long-lasting performance and reliability.

Key Features of IGOLDENCNC’s 5-Axis CNC Routers

Advanced Controller: These routers use advanced controllers, simplifying intricate multi-axis control.

High-Powered Spindle: With a robust spindle, IGOLDENCNC routers cut efficiently through tough materials like stone and metal.

Enhanced Accuracy: Thanks to the stability of their frames and the precision of their motors, IGOLDENCNC routers deliver unparalleled accuracy, ideal for professional applications.

Applications of IGOLDENCNC’s 5-Axis CNC Routers

IGOLDENCNC’s 5-axis routers are widely used across industries, including:

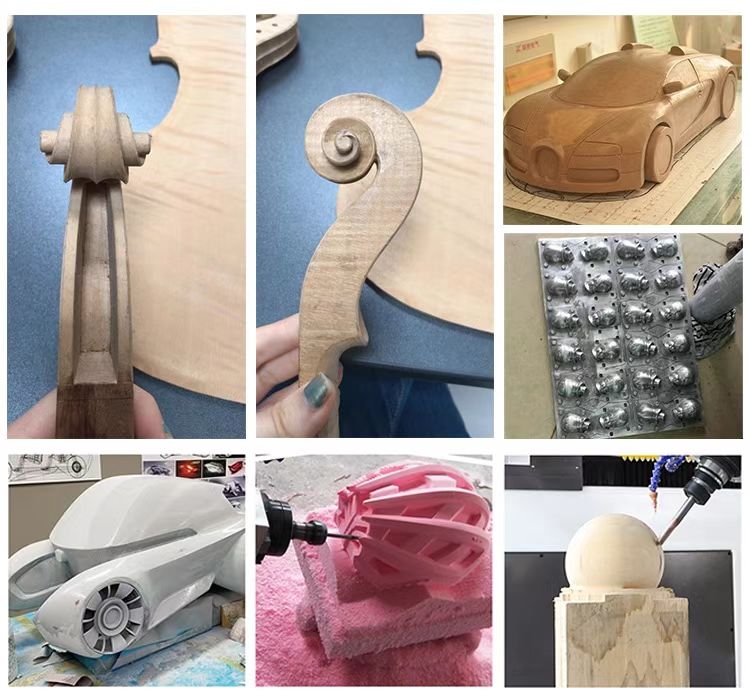

Prototyping and Product Design: Produce highly detailed prototypes and custom parts.

Stone and Woodworking: Carve complex 3D shapes in marble, granite, or hardwood with ease.

Metal Fabrication: Create intricate metal components for machinery, automotive, and aerospace applications.

Cost Breakdown: Homemade vs. Professional 5-Axis CNC Routers

If you’re considering building a 5-axis router, here’s a rough estimate of costs:

Homemade 5-Axis CNC Router Cost:

- Frame and Gantry: $200 – $500

- Stepper Motors: $200 – $400

- Spindle: $100 – $300

- Controller Board: $50 – $150

- Rotary Components for Axes: $100 – $200

- Miscellaneous (screws, wires, etc.): $50 – $100

Total Estimated Cost: $800 – $2,000

IGOLDENCNC 5-Axis CNC Router Cost:

While a professional-grade IGOLDENCNC router may cost more, the time saved, reliability, and support provided make it a valuable investment for businesses and serious enthusiasts. IGOLDENCNC’s machines generally start around $10,000 and go up based on features and size.

Tips for Maximizing the Performance of a Homemade CNC Router

- Prioritize Precision: Regularly calibrate your machine and check for alignment issues to maintain precision.

- Use Quality Software: Invest in good software for designing and converting files, such as Fusion 360 or Mach3, to ensure smooth multi-axis operation.

- Ensure Proper Cooling: CNC routers can heat up quickly, so adding a cooling system, especially for the spindle, is essential to prevent overheating.

- Routine Maintenance: Clean and inspect moving parts to keep them free from dust and debris, which can hinder performance.

Creating an affordable homemade 5-axis CNC router offers endless possibilities for custom, precise cuts. For hobbyists with technical skills, a DIY approach is a cost-effective way to explore CNC capabilities. However, if you’re seeking professional reliability and are ready to invest, IGOLDENCNC’s 5-axis routers provide advanced functionality, durability, and unmatched precision. With IGOLDENCNC, you gain not only high-quality equipment but also comprehensive support for your CNC projects, making it a smart choice for those aiming for top-tier results.With the right planning, tools, and approach, you can decide whether to go DIY or invest in a professional IGOLDENCNC router to bring precision machining into your workshop or business.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.