Blog

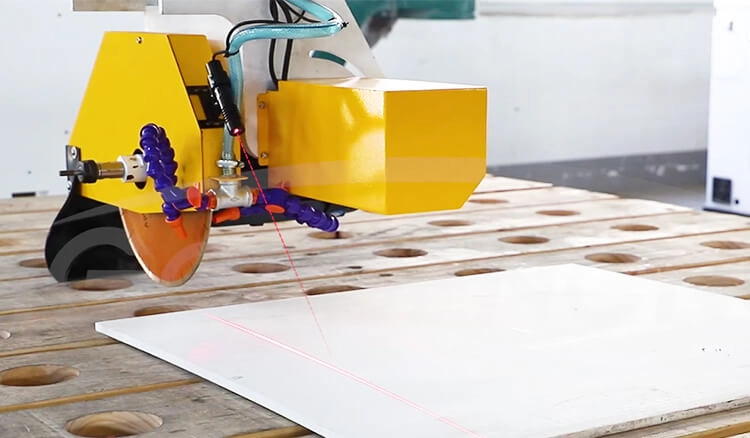

Professional CNC Router for Stone: Cutting, Engraving & Shaping

CNC router for stone have transformed how professionals approach tasks like cutting, engraving, and shaping. From architectural features and monuments to detailed artistic carvings, CNC routers provide a level of accuracy and speed that traditional tools can’t match. In this article, we explore the advantages of CNC routers for stone, what to look for in a professional machine, and why IGOLDENCNC is a trusted provider for stone-working solutions.

Why Choose CNC Routers for Stone?

CNC routers for stone have become essential for achieving complex and intricate designs. These machines operate on multiple axes (such as X, Y, and Z) and can move precisely, creating fine details without the risk of human error. Whether you’re working with granite, marble, limestone, or quartz, CNC routers offer several advantages:

- Precision: CNC routers use computer programming to make precise cuts and engravings, essential for creating complex patterns or replicating designs consistently.

- Efficiency: Automated processes reduce production time, allowing professionals to complete projects faster and at a lower cost.

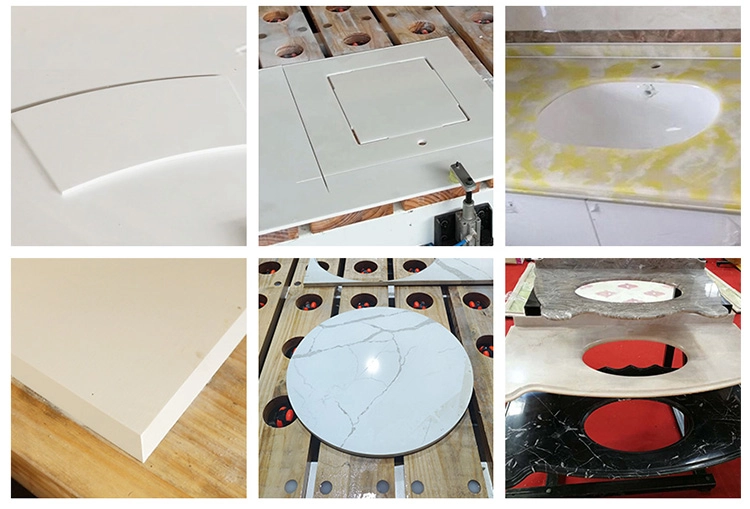

- Versatility: CNC routers handle various tasks like cutting, shaping, drilling, engraving, and polishing, making them suitable for diverse stone applications.

- Repeatability: CNC routers can reproduce the same design with high consistency, essential for large production runs or custom orders.

Key Features of Professional CNC Routers for Stone

To achieve professional-grade results, a CNC router must be equipped with certain features tailored to stone processing. Here’s what to consider:

1. Robust Frame and Durability

- Stone CNC routers must withstand the heavy-duty demands of stone cutting. A stable, reinforced frame helps maintain accuracy even when working with dense materials like granite and marble.

- The machine’s durability ensures a longer lifespan, reducing maintenance costs over time.

2. High-Power Spindles

- High-power spindles are necessary to cut through hard stone effectively. Look for spindles with adjustable speeds, which allow for more precise control over cutting depth and speed for different types of stone.

3. Cooling Systems

- Working with stone generates significant heat, so an efficient cooling system is essential. Water-cooled spindles help dissipate heat, preventing tool wear and keeping the material from overheating or cracking.

4. Dust Protection and Collection

- Stone cutting produces a large amount of dust and debris. A dust collection and protection system safeguards both the machine components and the operator, ensuring smoother operations and a safer work environment.

5. Advanced Software Compatibility

- Professional CNC routers must be compatible with advanced CAD/CAM software. This enables precise design control and allows users to import and execute intricate designs.

Top Applications of CNC Routers for Stone

CNC routers have opened new possibilities in the stone processing industry, allowing for diverse applications across various fields. Here are some common applications:

1. Architectural Stonework

- From intricate columns to decorative panels, CNC routers enable the creation of unique architectural details. These machines bring precision and speed to custom designs, enhancing building exteriors, interiors, and landscape elements.

2. Monuments and Tombstones

- Engraving text, symbols, and images onto monuments and tombstones is a popular use of stone CNC routers. The machines allow for precise, customizable designs to meet specific client requirements.

3. Countertops and Kitchen Surfaces

- For kitchens, CNC routers help cut and shape countertops, sink cutouts, and edge profiles with a clean, smooth finish. This application is ideal for materials like quartz and granite, which require both precision and strength.

4. Artistic Carvings and Sculptures

- Artists use CNC routers to create intricate stone sculptures and art pieces, achieving fine details that are hard to replicate manually.

5. Flooring and Wall Panels

- CNC routers facilitate the production of decorative stone flooring, wall panels, and mosaic designs. These products add visual interest to both residential and commercial spaces.

Benefits of Choosing IGOLDENCNC for Your Stone CNC Router

Investing in an IGOLDENCNC stone CNC router provides several distinct advantages:

- Precision and Consistency: With IGOLDENCNC’s high-performance machines, you can expect precise cuts and consistent quality on every piece. This is essential for businesses producing high-end, custom stone products.

- Customizability: Each IGOLDENCNC machine can be configured to match your specific project needs. From spindle power to table size, our machines are adaptable to a variety of requirements.

- User-Friendly Operation: IGOLDENCNC machines are compatible with popular CAD/CAM software, making it easy for users to design and execute complex patterns without extensive training.

- Long-Term Support and Warranty: We provide comprehensive after-sales support and a robust warranty, ensuring that you receive assistance when needed. Our technical support team is available to help with maintenance, troubleshooting, and upgrades.

- Affordable Quality: While IGOLDENCNC offers professional-grade quality, we maintain competitive pricing to help businesses achieve high performance without overspending.

How to Choose the Right CNC Router for Your Stone Projects

When selecting a CNC router for stone processing, consider the following factors to ensure it aligns with your needs:

- Material Type: Consider the types of stone you’ll be working with. Some models are better suited for softer stones, while others are equipped to handle harder materials like granite.

- Project Size: If you require large-scale production, look for models with larger work tables. Conversely, smaller, more detailed projects may benefit from a compact, precision-focused machine.

- Software Compatibility: Make sure the CNC router is compatible with CAD/CAM software for easy design integration and automation.

- Budget: Evaluate your budget and consider the long-term ROI. Higher-end models may require a larger investment but often provide greater durability and efficiency.

Choosing a professional CNC router for stone can significantly enhance your capabilities in cutting, engraving, and shaping stone materials. IGOLDENCNC offers a range of high-quality machines, each engineered for precision, durability, and versatility in stone applications. Whether you’re working on architectural projects, monuments, or custom art pieces, IGOLDENCNC has a solution tailored to meet your needs.

By selecting a trusted provider like IGOLDENCNC, you invest in more than just a machine—you gain a reliable partner for your business growth. Contact IGOLDENCNC today to learn more about our stone CNC routers and get a personalized recommendation for your next project.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.