Blog

Top CNC Machine Stone for Cutting, Shaping, and Engraving

CNC machines for stone are revolutionizing the way businesses approach stone cutting, shaping, and engraving. These powerful machines enable you to achieve precise, high-quality results with a variety of stone materials, such as marble, granite, and quartz. Whether you’re in the business of countertop production, monument engraving, or custom stone sculptures, having the right CNC stone machine is key to boosting efficiency and precision.

At IGOLDENCNC, we specialize in providing advanced CNC machines designed specifically for stone processing. In this guide, we’ll walk you through the benefits of CNC machines for stone, introduce the top models we offer, and explain how they can enhance your stoneworking operations.

What is a CNC Machine for Stone?

A CNC machine for stone uses computer-controlled technology to perform cutting, engraving, and shaping tasks with precision. Unlike traditional manual methods, CNC machines automate the process, which results in faster production times, higher accuracy, and the ability to handle intricate designs with ease.

These machines are equipped with powerful tools such as diamond blades, routers, and engraving bits, all of which can work with a variety of stone materials. Whether you’re fabricating countertops, creating custom monuments, or engraving detailed designs, CNC machines offer the flexibility and power you need to execute complex stone projects.

Why Choose CNC Machines for Stone?

Precision and Accuracy

CNC machines are renowned for their ability to execute precise cuts and designs. They can carve intricate patterns, cut through thick stone slabs, and create perfectly smooth surfaces with minimal error. This level of precision is critical for industries such as monument engraving, custom tile production, and countertop manufacturing.

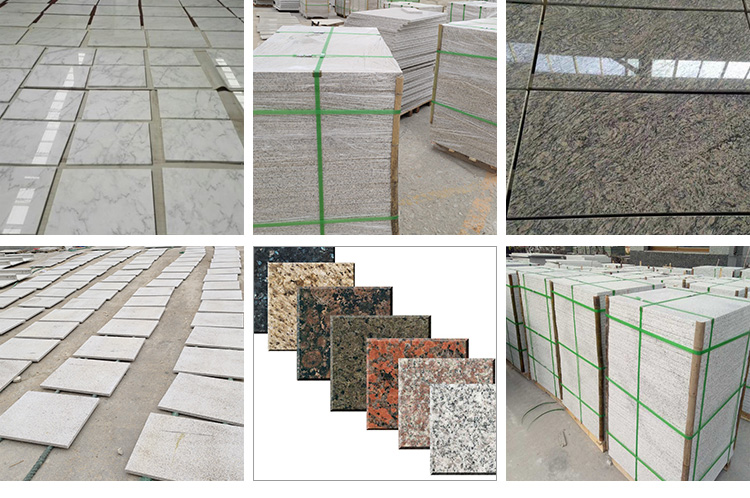

Versatility Across Stone Types

One of the standout features of CNC machines is their ability to process various types of stone, including:

- Granite

- Marble

- Quartz

- Limestone

- Travertine

Whether you’re cutting a granite countertop or engraving a marble monument, a CNC stone machine can handle the material and the task.

Speed and Efficiency

CNC machines can operate for hours at a time without needing breaks, making them ideal for large-scale stone processing. Their speed allows you to meet tight deadlines while maintaining high-quality results. Automation also minimizes human error, increasing production efficiency and reducing material waste.

Cost-Effectiveness

Although CNC machines require an upfront investment, they prove to be cost-effective in the long term. With reduced labor costs, faster production times, and minimized waste, you’ll see a return on your investment quickly. Additionally, the precision of CNC machines reduces the likelihood of errors that could otherwise lead to costly rework.

Top CNC Stone Machines at IGOLDENCNC

At IGOLDENCNC, we offer a range of CNC machines designed to tackle all aspects of stone processing, from cutting and shaping to engraving and polishing. Below, we’ll introduce you to some of our best-selling CNC stone machines:

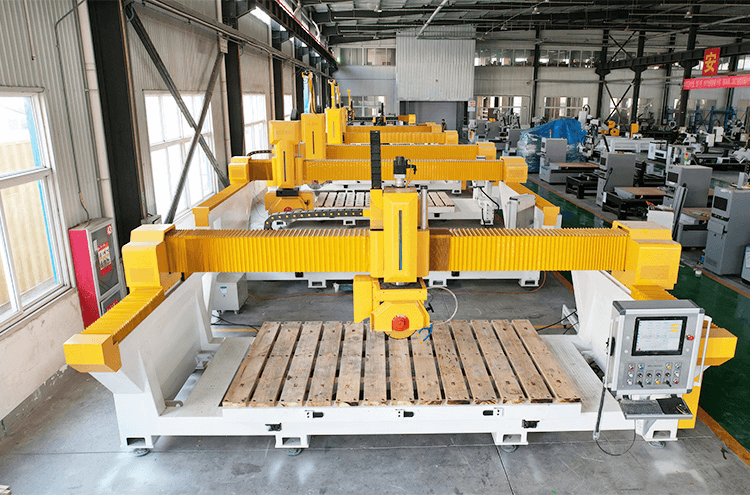

5-Axis CNC Stone Cutting Bridge Saw

The 5-Axis CNC Stone Cutting Bridge Saw is a versatile, high-performance machine capable of making intricate cuts and detailed shapes. With its five axes of movement, it can cut both straight and curved edges, chamfer surfaces, and even make inclined cuts with ease.

Key Features:

- 5-Axis Movement: Ideal for complex stone cuts and curved edges.

- High-Speed Cutting: Cuts through thick stone slabs quickly and accurately.

- Advanced Software: Allows for easy programming of custom cutting paths.

- Material Compatibility: Works with granite, marble, quartz, and more.

Applications: This machine is perfect for large-scale stone processing, such as countertop production, wall cladding, and monument cutting.

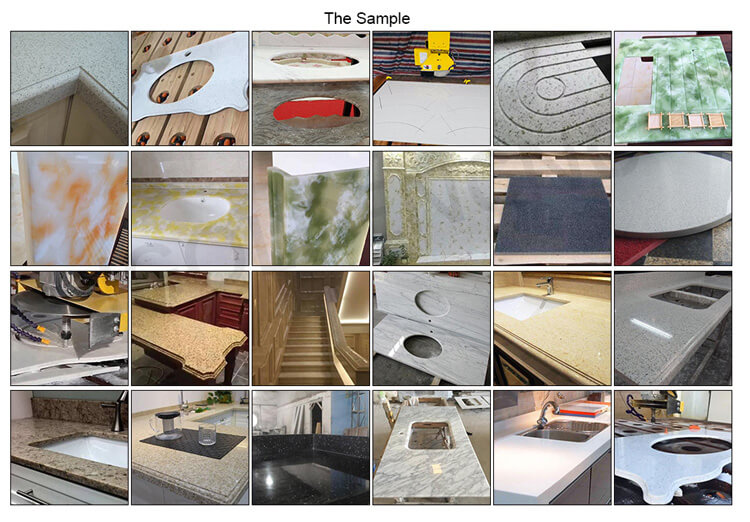

CNC Stone Engraving Machine

The CNC Stone Engraving Machine specializes in precision engraving, allowing you to create detailed patterns, text, and images on stone surfaces. Whether you’re making custom memorials, decorative plaques, or signage, this machine offers the detail and accuracy you need.

Key Features:

- High-Precision Engraving: Capable of carving intricate designs and text on stone.

- Adjustable Depth and Speed: Customizable settings for various engraving tasks.

- Wide Compatibility: Works with a range of stone materials like granite and marble.

- User-Friendly Interface: Easy-to-learn software for designing and executing engraving jobs.

Applications: Ideal for memorial engraving, custom signage, decorative stone carvings, and artwork.

CNC Stone Cutting Router

The CNC Stone Cutting Router is a versatile machine that handles both cutting and engraving tasks. With its robust build and high precision, it can carve through tough stone materials and produce high-quality finished products.

Key Features:

- Multi-Functional: Capable of both cutting and engraving, making it a highly versatile tool.

- Durable Construction: Designed to handle heavy-duty stone materials.

- Precision Movement: Ensures fine details and accurate cuts on both large and small projects.

Applications: Great for fabricating kitchen countertops, custom stone sculptures, and decorative tiles.

CNC Stone Cutting Machine with Rotary Axis

The CNC Stone Cutting Machine with Rotary Axis is perfect for 3D stone carving and shaping. The rotary axis allows the machine to carve around cylindrical objects, such as columns, sculptures, and custom architectural features.

Key Features:

- Rotary Axis: Enables carving around cylindrical or 3D stone objects.

- High Precision: Ideal for creating detailed 3D designs and sculptures.

- Flexible Design Options: Suitable for various artistic and architectural applications.

Applications: Perfect for sculpting stone columns, 3D artworks, and custom architectural stone pieces.

CNC Bridge Saw for Large-Scale Stone Cutting

The CNC Bridge Saw is designed for high-speed, large-scale cutting. It is ideal for businesses that need to process large stone slabs quickly while maintaining precision.

Key Features:

- Heavy-Duty Performance: Built to handle large slabs of stone without sacrificing speed or accuracy.

- Multiple Cutting Options: Can cut straight, angled, and curved edges.

- Efficient Operation: Reduces time and labor costs for high-volume production.

Applications: Widely used in countertop manufacturing, cladding production, and large-scale stone cutting projects.

Why Choose IGOLDENCNC for Your CNC Stone Machine Needs?

At IGOLDENCNC, we pride ourselves on offering top-quality CNC machines for stone processing. Here’s why our customers choose us:

- Durability and Reliability: Our machines are built to last, ensuring that your investment will serve you for years to come.

- Customization: We offer customizable CNC solutions to fit the specific needs of your stone business.

- Global Reach: Serving customers worldwide, we offer prompt shipping and excellent customer support.

- Competitive Pricing: Get the best value for your money with our affordable and high-quality CNC machines.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.