Blog

Quartz CNC Machine: Precision Machining for Hard Materials

The Quartz CNC machine is a specialized piece of equipment designed to cut, shape, and polish quartz with extreme precision. These machines use diamond-tipped tools and advanced software to automate the machining process, ensuring that every cut is accurate and consistent. Whether you’re working with quartz for countertops, optical components, or semiconductor parts, a CNC machine offers the precision and efficiency needed to produce high-quality results.In this guide, we will explore the features, benefits, and applications of Quartz CNC machines

Precision machining of hard materials-Quartz CNC Machine

Large granite cutting machine, CNC stone cutting machine, large automatic stone five-axis bridge cutting machine, 360 ° infrared automatic bridge cutting machine, marble infrared bridge cutting machine adopts four-guide column lifting and lowering, the spindle uses FAG bearings, with high efficiency, high precision, easy operation, stable performance and other characteristics. It is suitable for cutting and processing of marble, granite, artificial stone and other large-size plates.

How Quartz CNC Machines Work

The process of CNC machining quartz involves several steps:

- Design: First, a digital design of the part or product is created using CAD (Computer-Aided Design) software. This design contains all the necessary dimensions and specifications for the quartz component.

- Programming: The CAD file is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software. This program contains the instructions for the CNC machine, including tool paths, cutting speeds, and feed rates.

- Machining: The CNC machine is set up with the appropriate cutting tools, usually diamond-tipped tools for quartz. The machine then follows the programmed instructions to cut, shape, or polish the quartz material. The machine moves in multiple axes (X, Y, and Z) to achieve the desired geometry.

- Finishing: After machining, the quartz component may undergo additional finishing processes, such as polishing or edge profiling, to achieve the desired surface finish.

Key Features of Quartz CNC Machine

When selecting a Quartz CNC machine, it’s important to consider the following key features, which are essential for machining hard and brittle materials like quartz:

1. Diamond-Tipped Tools

Quartz is extremely hard, with a Mohs hardness of 7, which means that standard cutting tools will wear out quickly. Diamond-tipped tools are essential for machining quartz, as they are capable of cutting through the material with precision and durability.

2. High-Speed Spindle

The spindle is the part of the CNC machine that rotates the cutting tool. For machining quartz, a high-speed spindle is necessary to achieve clean, precise cuts. Spindle speeds of 20,000 to 60,000 RPM are common for quartz machining, depending on the complexity of the design and the thickness of the material.

3. Multi-Axis Movement

Quartz CNC machines typically operate in three or more axes (X, Y, and Z), allowing for complex geometries and intricate designs to be machined. Some advanced machines offer 5-axis movement, which allows for even more flexibility in cutting and shaping quartz.

4. Coolant System

Machining quartz generates a significant amount of heat due to the friction between the cutting tool and the material. A coolant system is essential to dissipate this heat and prevent damage to the quartz. Coolant also helps to flush away dust and debris, keeping the cutting area clean and reducing tool wear.

5. Vacuum Hold-Down System

A vacuum hold-down system is used to secure the quartz material to the machine’s work surface, preventing it from shifting during machining. This ensures that each cut is accurate and consistent, even when working with large or heavy quartz slabs.

6. Automatic Tool Changer

Some Quartz CNC machines come with an automatic tool changer, which allows the machine to switch between different cutting tools without manual intervention. This is especially useful for complex designs that require multiple types of cuts, such as drilling, shaping, and polishing.

Benefits of Using a Quartz CNC Machine

Using a Quartz CNC machine offers several advantages over traditional machining methods. These benefits include:

1.Quartz CNC Machine Precision and Accuracy

Quartz CNC machines are capable of achieving extremely high levels of precision, often within micron-level tolerances. This is particularly important when machining quartz, as the material’s hardness and brittleness require precise control to avoid chipping, cracking, or other damage.

2. Consistency of Quartz CNC Machine

Because CNC machines are controlled by computer programs, they can produce consistent results across multiple parts. This is especially important for industries that require large quantities of identical quartz components, such as semiconductors or optical lenses.

3. Complex Geometries

Quartz CNC machines allow for the creation of complex shapes and geometries that would be difficult or impossible to achieve with manual machining methods. This is particularly useful for applications that require intricate designs, such as optical components or custom countertops.

4. Efficiency

CNC machining is an automated process, meaning that once the machine is programmed and set up, it can run with minimal human intervention. This increases production efficiency and allows for faster turnaround times, making it ideal for both prototyping and high-volume production.

5. Reduced Material Waste

CNC machines optimize cutting paths to minimize material waste, which is particularly important when working with expensive materials like quartz. Reducing waste can lead to significant cost savings, especially for large-scale projects.

Applications of Quartz CNC Machine

Various industries use quartz CNC machines to make high – precision components and products. Here are some of the common applications:

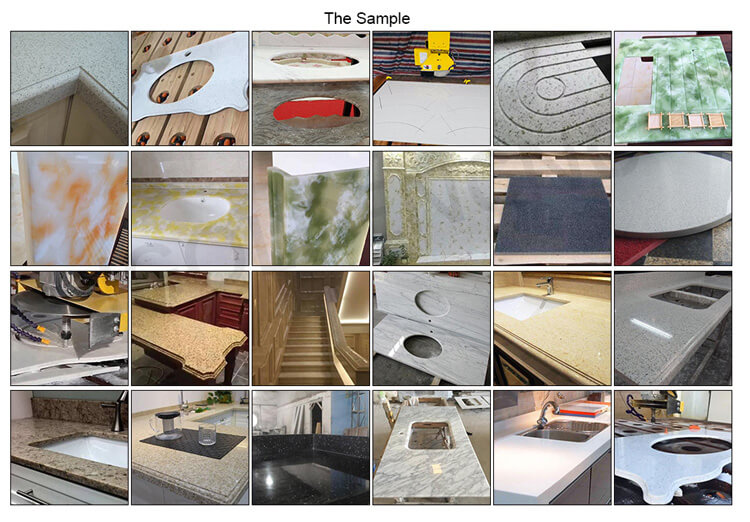

1. Quartz Countertops

People widely use Quartz CNC machines to produce quartz countertops. They use CNC machines to cut and shape quartz slabs into custom countertop designs, including sink cutouts, edge profiles, and backsplashes. The precision of CNC machining guarantees that each countertop fits precisely in its designated space.

2. Semiconductor Components

The semiconductor industry widely uses quartz because of its chemical resistance and thermal stability. Manufacturers use CNC machines to create precise quartz components for semiconductor manufacturing equipment, such as wafer carriers, etching chambers, and optical components.

3. Optical Lenses and Components

People also use quartz in the production of optical lenses and components for applications like microscopes, telescopes, and laser systems. CNC machining enables the creation of highly precise and intricate lens shapes to ensure optimal optical performance.

4. Quartz Tubes and Rods

Industries such as pharmaceuticals and laboratory equipment use quartz tubes and rods for their chemical resistance and thermal stability. Workers use CNC machines to cut and shape these components to exact specifications to ensure they meet the requirements of their intended applications.

5. Custom Quartz Parts

People also use CNC machines to produce custom quartz parts for various industries, including aerospace, medical devices, and electronics. These parts often require high precision and complex geometries, which CNC machines are good at producing.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.